CNC Machining for the Chemical Industry: Corrosion-Resistant Material Choices

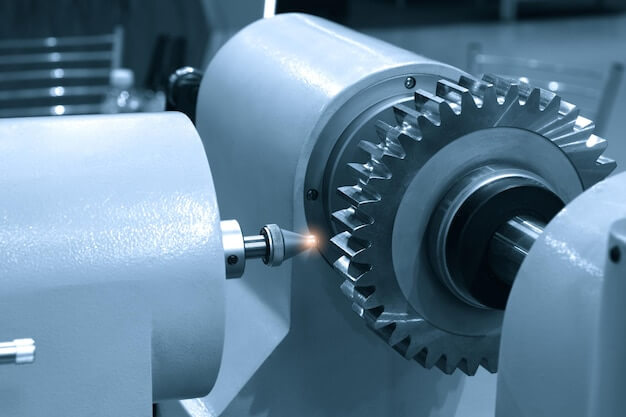

Introduction to CNC Machining in the Chemical Industry CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, offering precision and efficiency by automating the control of machine tools with computer systems. Its significance is particularly pronounced in the chemical industry, where the demand for corrosion-resistant materials is high. This industry requires components […]

CNC Machining of Hard Materials: Diamond-Like Coatings for Enhanced Performance

Introduction to CNC Machining CNC (Computer Numerical Control) machining stands as a pivotal technology in manufacturing, enabling the precise and automated shaping of materials based on digital instructions. This method is crucial for working with hard materials, such as metals and composites, which are integral in industries ranging from aerospace to medical devices. By leveraging […]

CNC Machining of Exotic Materials: Inconel, Titanium, and Monel

CNC Machining and Exotic Materials: Inconel, Titanium, Monel The art and science of creating objects from metal via the precise movements of cutting tools on a computer numerical control (CNC) machine is referred to as CNC machining. This method enables high levels of accuracy, repeatability, and speed during the formation of complex parts. Enabling businesses […]

Evaluating the Use of Beryllium Copper in CNC Machining for Aerospace Applications: Is It Safe and Effective?

Introduction: Beryllium Copper’s Role in CNC Machining for Aerospace Applications The advanced manufacturing industry, especially aerospace where safety and effectiveness are of prime importance, heavily relies on robust materials to meet the stringent application requirements. One of these materials is Beryllium Copper (BeCu), predominantly used in Computer Numerical Control (CNC) machining due to its unique […]

Zirconium vs. Titanium: Comparing CNC Machinability and Corrosion Resistance?

CNC Machinability and Corrosion Resistance: Zirconium vs Titanium The manufacturing industry often has to juggle a plethora of considerations while selecting materials for product manufacture. Top among these are two properties; CNC machinability and corrosion resistance. CNC (Computer Numerical Control) machinability refers to the ease with which a material can be shaped using automated machining […]

The Use of Bronze Alloys in CNC Machining for Maritime Engineering: Corrosion Resistance and Durability

Bronze Alloys and CNC Machining in Maritime Engineering Maritime engineering, a field associated with the design, building and maintenance of structures used at sea, frequently employs both Computer Numeric Control (CNC) machining and bronze alloys for various applications. Bronze alloys especially serve as popular materials due to their exceptional corrosion resistance characteristics and durability which […]

Titanium Grade 5 vs. Grade 23 for CNC Machining: Understanding the Differences and Applications?

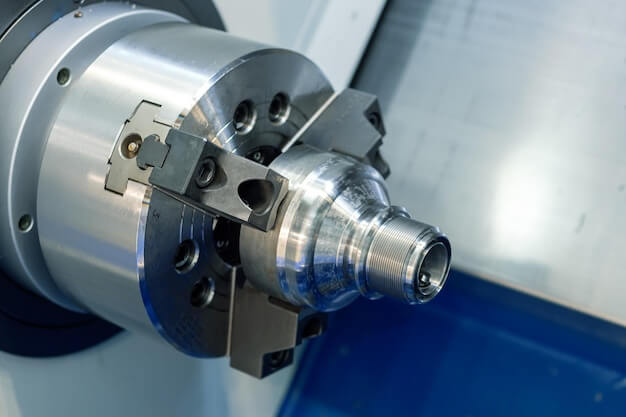

Understanding CNC Machining and Titanium Grades CNC (Computer Numerical Control) machining is a fundamental manufacturing process in many industries. It utilizes automated controls and cutting tools to remove material from a workpiece, shaping desired components accurately and efficiently. One must carefully select the material for this process based on its properties and required application. Among […]

Titanium Grade 5 vs. Grade 23 in CNC Machining: Which is More Efficient?

Introduction: Titanium Grade 5 vs. Grade 23 in CNC Machining In the realm of Computer Numerical Control (CNC) machining, the use of titanium-based materials is quite prevalent due to their excellent strength-to-weight ratio and corrosion resistance. Primarily, two types of titanium are used – Grade 5(Ti-6Al-4V) and Grade 23 (Ti-6Al-4V ELI). While Grade 5 is […]

PEEK Plastic in CNC Machining: Is It a Viable Alternative to Metals for High-Performance Parts?

Introduction to PEEK Plastic and CNC Machining The realm of material science welcomes a game-changing contender, popularly known as PEEK (Polyether Ether Ketone) plastic. A high-performance thermoplastic, PEEK boasts remarkable mechanical properties such as high-temperature stability, excellent chemical resistance, superior strength, stiffness and durability. It provides an edge for industries that necessitate robust materials with […]

Enhancing the Mechanical Properties of CNC Machined Parts through Material Blending

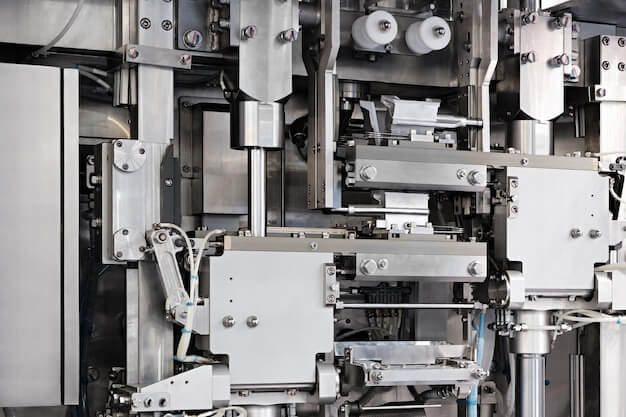

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated production of complex parts. This process relies on computerized controls and machine tools to remove layers from a solid block of material, thus shaping the desired part. The significance of CNC machining lies in […]

Thermal Management in CNC Machining: Selecting Materials for Heat Dissipation

Introduction to CNC Machining and Thermal Management CNC machining stands as a cornerstone in modern manufacturing, utilizing computer numerical control to operate machine tools with high precision. This process is pivotal for creating intricate parts with tight tolerances across various industries. A critical aspect often overlooked is thermal management within CNC machining processes. Effective thermal […]

Material Properties and Their Influence on CNC Machining Vibrations and Finishes

Introduction to CNC Machining CNC machining stands as a cornerstone in modern manufacturing, offering precision and efficiency in producing parts. At its core, CNC (Computer Numerical Control) machining involves the use of computers to control machine tools, ensuring high accuracy and repeatability. The importance of CNC machining in manufacturing cannot be overstated, as it enables […]