CNC Machining with Inconel: Challenges and Solutions for High-Temperature Alloys?

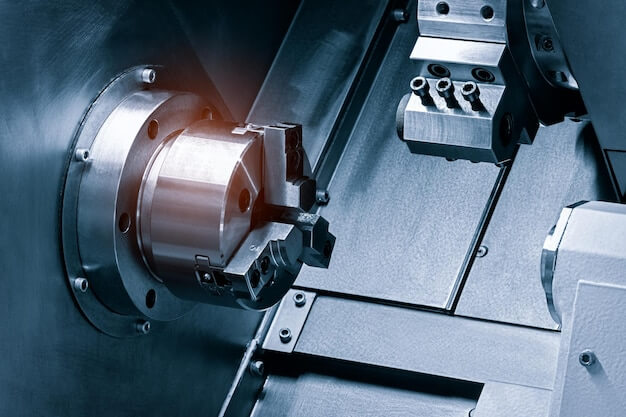

Introduction to CNC Machining with Inconel In the realm of Computer Numerical Control (CNC) machining, utilizing high-temperature alloys such as Inconel presents a unique set of challenges. Notorious for its difficulty to machine due to high tensile strength and abrasive properties, Inconel can negate traditional machining techniques, affect tool life negatively, and lead to substandard […]

Titanium Grade 5 vs. Grade 23 in CNC Machining: Which Provides Superior Performance?

Introduction to CNC Machining and Titanium Grades CNC Machining, short for Computer Numerical Control machining, is a manufacturing process which employs computerized controls to manipulate different types of machinery such as mills, lathes, grinders, and routers. This advanced technology enables precise control over complex cuts needed in the production of components made from various materials […]

Precision Engineering: The Role of Microstructure in Material Selection for CNC

Introduction to Precision Engineering and CNC Machines Precision engineering is a critical aspect of modern manufacturing, focusing on the design, development, and implementation of highly accurate components and systems. This discipline is essential for creating parts with very tight tolerances, ensuring that they fit and function as intended in a variety of applications. A key […]

Wear Resistance in CNC Machining Tools: Carbide vs. High-Speed Steel Materials

Introduction to CNC Machining Tools CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated shaping of materials into finished products. This process relies heavily on specialized tools that execute the cutting, drilling, and milling operations under computer guidance. A critical aspect of these tools is their wear […]

The Role of Aluminum Alloys in Modern CNC Machining: A Cost and Performance Analysis

Introduction: CNC Machining and the Importance of Materials Used in the Process CNC machining or Computer Numerical Control machining is a globally adopted manufacturing process involving pre-programmed computer software to dictate the movement of factory tools and machineries. It plays an essential role in modern engineering due to its capability to produce intricate parts with […]

Material Strength vs. Machinability: Finding the Balance for Efficient CNC Operations

Introduction to CNC Operations Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the automated control of machine tools by means of a computer. A pivotal aspect of ensuring efficient CNC operations lies in the selection of appropriate materials. This choice directly influences not only the machining process itself but also […]

Nickel Alloys in CNC Machining: Inconel 718 vs. Monel K-500 for Aerospace and Marine Applications?

Introduction to CNC Machining and Nickel Alloys Computer Numeric Control (CNC) machining is a pivotal process in the manufacturing industry, using pre-programmed computer software to dictate the movement of factory machinery and tools. The use of various materials during this process plays a critical role, with nickel alloys earning a special mention due to their […]

The Role of Aerospace Grade Aluminum in CNC Machining: Is it the Best Choice?

The Role of Aerospace Grade Aluminum in CNC Machining: An Introduction CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It plays an essential role in many industries, particularly aerospace due to its precision and efficiency. A crucial element behind this precision involves […]

Material Selection for CNC Machining in the Medical Device Industry: Titanium vs. Stainless Steel

Introduction: CNC Machining in the Medical Device Industry and Importance of Material Selection The application of Computer Numerical Control (CNC) machining in the medical device industry is increasingly imperative due to its ability to fabricate intricate components with impeccable precision. In this high-stakes field where reliability, durability, and biocompatibility are paramount, careful material selection for […]

Optimizing CNC Machining for Aerospace Components: A Material Perspective

Introduction The role of Computer Numerical Control (CNC) machining in the aerospace industry is critical in maintaining the precision and integrity of vital components. With its ability to automate complex cutting tasks, CNC machining significantly contributes to efficient production processes. More importantly, CNC machines can work with a wide range of materials all tailored for […]

CNC Machining in Aerospace: Optimizing for Lightness and Strength

Introduction to CNC Machining in Aerospace CNC (Computer Numerical Control) machining stands as a cornerstone in the aerospace industry, enabling the precise fabrication of components. This technology is pivotal for crafting parts that meet the stringent requirements of aerospace applications, focusing primarily on enhancing lightness and strength. By leveraging CNC machining, manufacturers can produce complex […]

Overcoming Challenges in CNC Machining with Soft Materials: Techniques and Tips

Introduction to CNC Machining and Challenges with Soft Materials CNC (Computer Numerical Control) machining is a core operation in the manufacturing sector, powering the production of complex parts across various industries. It involves programming computers to direct machinery, such as mills, grinders and lathes, to manufacture components to precise specifications. Despite its versatility, working with […]