Introduction to CNC Machining and 3D Printing

CNC machining and 3D printing stand as pivotal technologies in the manufacturing sector, each playing a unique role in how objects are created. CNC (Computer Numerical Control) machining is a process where pre-programmed computer software dictates the movement of factory tools and machinery, allowing for the precise cutting, milling, and shaping of materials. On the other hand, 3D printing, or additive manufacturing, involves creating objects by layering materials based on digital models, offering a versatile approach to manufacturing complex designs with less waste. The evolution of machining metals has been significantly influenced by these technologies, transitioning from manual labor-intensive processes to automated and highly accurate methods. This shift not only enhances production efficiency but also opens up new possibilities in the use of materials and the complexity of designs that can be achieved.

- CNC Machining: Automates cutting, milling, and shaping of materials through computer control.

- 3D Printing: Builds objects by adding material layer by layer, allowing for complex designs.

Understanding Traditional Machining

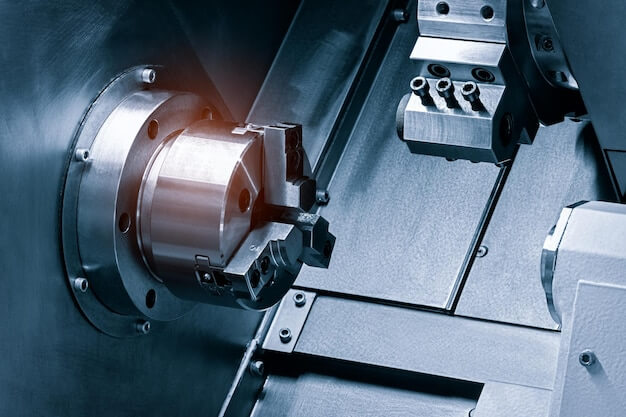

Traditional machining is a foundational manufacturing process that shapes metal and other materials through subtractive methods. This approach involves removing material from a workpiece to form the desired shape. A common example is using a milling machine to carve a piece out of a metal block. The process typically follows these steps:

- Designing the part: A blueprint or digital model is created to guide the machining process.

- Setting up the machine: The workpiece is securely fixed, and the appropriate cutting tools are selected and installed.

- Machining the part: The machine follows the design instructions to cut away excess material, shaping the workpiece into its final form.

- Finishing touches: Additional processes such as polishing or coating may be applied to finish the part.

This method is highly versatile, capable of producing a wide range of parts with precision. However, it inherently involves material waste as excess material is cut away and cannot be reused in the same process.

The Rise of 3D Printing in Metal Fabrication

3D printing, a cornerstone of additive manufacturing, revolutionizes metal fabrication by constructing objects layer by layer. Unlike traditional subtractive methods that carve out material, 3D printing adds material only where needed, significantly reducing waste. This process begins with a digital model, which a printer then translates into a physical object by melting and fusing layers of metal powder. Key components of this process include:

- Digital Model: A 3D blueprint of the object to be printed.

- Metal Powder: The raw material, available in various alloys.

- Printer Nozzle: Heats and deposits the metal powder.

- Layering Process: Adds material layer by layer to build the object.

For example, creating a complex metal part like a turbine blade becomes more efficient and precise, showcasing the method’s ability to produce components with intricate geometries that are challenging or impossible to achieve through traditional machining.

Comparing Techniques: Precision and Applications

When comparing precision and applications of CNC machining and 3D printing, it’s essential to consider factors such as material versatility, surface finish, and production volume. CNC machining offers high precision and is well-suited for metal materials, making it ideal for applications requiring tight tolerances and intricate designs. On the other hand, 3D printing provides versatility in geometric complexity and is advantageous for rapid prototyping and low-volume production. Understanding the specific requirements of the project is crucial in determining the most suitable technique for achieving precision and meeting application needs.

Material Considerations and Limitations in CNC Machining and 3D Printing Metals

Both CNC machining and 3D printing metals have distinct material capabilities and limitations that are crucial for manufacturers to understand. CNC machining is versatile, working with a wide range of materials including metals like aluminum, steel, and titanium, as well as plastics and composites. However, its limitations lie in the material’s machinability; harder materials require more time and cost to machine. On the other hand, 3D printing metals primarily focuses on materials that can be powdered such as stainless steel, titanium, and nickel alloys. While 3D printing offers the advantage of creating complex geometries that would be difficult or impossible to achieve with CNC machining, it is limited by the types of materials that can be effectively powdered and sintered without compromising the structural integrity of the printed object.

- CNC Machining Materials: Aluminum, Steel, Titanium, Plastics, Composites.

- 3D Printing Metals: Stainless Steel, Titanium, Nickel Alloys.

For example, titanium is a material that both techniques can work with, but the approach and outcome can significantly differ. In CNC machining, titanium’s toughness can lead to increased tool wear and longer machining times, whereas in 3D printing, titanium powder can be used to create lightweight, complex structures without the same level of tool degradation.

Cost and Time Efficiency in CNC Machining vs. 3D Printing Metals

The comparison between CNC machining and 3D printing metals in terms of cost and time efficiency reveals distinct advantages and challenges for each method. CNC machining is traditionally known for its precision and reliability in producing metal parts. However, the initial setup costs and the cost of materials can be high, especially for complex parts. In contrast, 3D printing offers a more cost-effective solution for producing complex geometries without the need for expensive tooling. The material costs for 3D printing can be lower, but the type of metal powder required can also influence the overall cost.

- Cost Efficiency: CNC machining incurs higher initial costs due to tooling and setup, while 3D printing reduces these expenses, making it cost-effective for small batches and complex designs.

- Time Efficiency: CNC machining is time-consuming for complex parts due to the need for multiple setups and tool changes. 3D printing, on the other hand, can produce complex parts in a single operation, significantly reducing production time.

For example, producing a complex aerospace component might require several hours or even days of machining time, along with the associated costs of the tools and materials. Using 3D printing, the same part could be produced in a fraction of the time, with less material waste and without the need for multiple setups.

Environmental Impact and Sustainability of CNC Machining and 3D Printing Metals

The environmental considerations of CNC machining and 3D printing metals are crucial in assessing their sustainability. CNC machining, traditionally known for its precision, often results in significant material waste as the process involves subtracting material to shape the final product. Efforts to enhance its sustainability include optimizing cutting paths to minimize waste and recycling metal scraps. On the other hand, 3D printing metals, also known as additive manufacturing, is inherently more material-efficient since it builds objects layer by layer, using only the necessary material. This process reduces waste and energy consumption, making it a greener alternative. However, the sustainability of 3D printing also depends on the source of the metal powders used, pushing for the development of recycled powders. Both methods are evolving with a focus on reducing environmental impact through:

- Improved material efficiency

- Recycling of waste materials

- Reduction in energy consumption

For example, the adoption of closed-loop recycling systems in CNC machining facilities can significantly reduce waste, while the use of solar energy to power 3D printers can lower the carbon footprint of metal additive manufacturing.

Future Trends in Metal Manufacturing

The evolution of metal manufacturing is poised for significant advancements, with CNC machining and 3D printing technologies at the forefront. These two methods are expected to evolve in ways that complement each other, enhancing the efficiency and capabilities of metal manufacturing. For instance:

- Integration of AI and Machine Learning: Predictive maintenance, optimized tool paths, and real-time adjustments during machining processes will become standard, reducing waste and increasing precision.

- Hybrid Manufacturing Systems: Machines that combine the subtractive precision of CNC machining with the additive capabilities of 3D printing will become more prevalent. This will allow for the creation of complex parts with internal structures that were previously impossible or too costly to produce.

- Material Innovations: The development of new metal alloys and composite materials specifically designed for 3D printing will expand the range of applications for metal parts, including in aerospace, automotive, and medical industries.

- Environmental Sustainability: Both technologies will advance towards more sustainable practices, including the use of recycled materials and energy-efficient processes, to minimize the environmental impact of manufacturing.

These advancements will not only improve the quality and efficiency of metal manufacturing but also open up new possibilities for design and production that are currently unimaginable.

Other Articles You Might Enjoy

- Understanding Rivets and Tack Welding Through CNC Machining( lightweight metal Brian)

CNC (Computer Numerical Control) machining is an advanced technology that has revolutionized the manufacturing industry. This transformative technique allows for precise control in processing materials such as metal, plastic, foam,…

- CNC Machining of Stainless Steel: Tips and Common Pitfalls?

CNC Machining and the Importance of Stainless Steel Computer Numerical Control (CNC) machining is a production process whereby pre-programmed computer software directs the movement of factory machinery or tools, enabling…

- Mastering Rivets and Tack Welding in CNC Machining(bending sheet metal Violet)

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry, enabling the production of complex parts with precision and efficiency. This article aims to shed light on two critical aspects…