Introduction: Bridging Precision and Innovation

In the realm of modern manufacturing, precision is not just a requirement; it’s an art form. Particularly in the production of bearings, an essential component in myriad mechanical systems, the integration of China’s CNC (Computer Numerical Control) machining services with advanced surface treatment techniques represents a pivotal evolution. This fusion not only enhances the functionality and lifespan of bearings but also propels the industry towards unprecedented levels of efficiency and quality.Chinese companies can also provide online cnc machining services to provide customized bearing processing services to global customers.

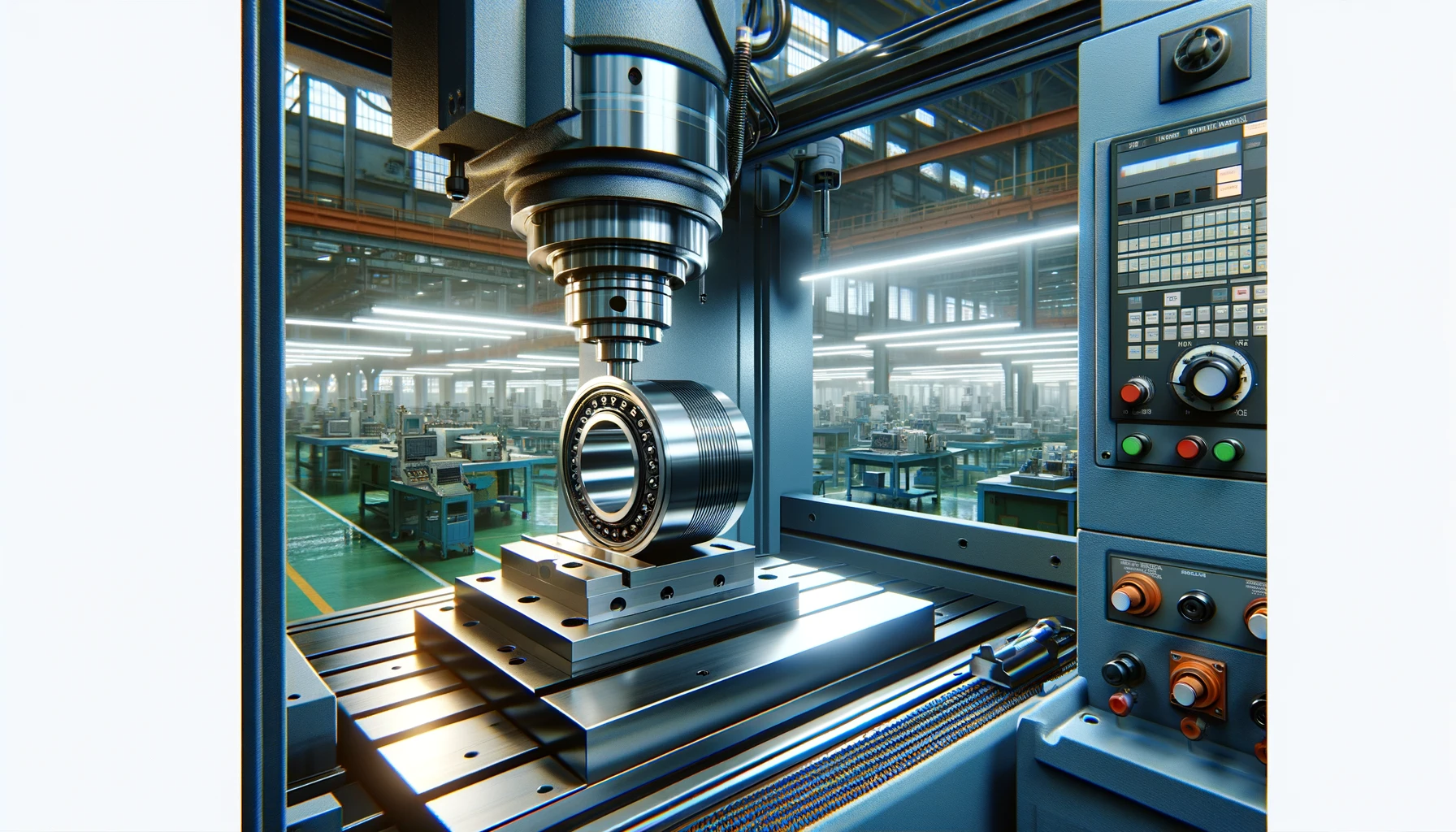

The Essence of China’s CNC Machining in Bearing Manufacturing

China’s prowess in CNC machining is a testament to its commitment to precision engineering. CNC machines, with their ability to follow precisely programmed sequences, offer unparalleled accuracy in the manufacturing of complex bearing components. For instance, a leading manufacturer in Zhejiang Province utilizes high-precision CNC lathes to craft the inner and outer races of bearings. These machines ensure that each component adheres to exacting tolerances, essential for the optimal performance of bearings in high-stress applications like aerospace and automotive industries.

Advanced Surface Treatment Techniques: Elevating Bearing Performance

Surface treatment, the process of altering the surface of a material to achieve certain properties, is critical in bearing manufacturing. Techniques such as nitriding, used by a prominent Shanghai-based bearing manufacturer, involve diffusing nitrogen into the surface of steel components to enhance their hardness and resistance to wear. This treatment significantly extends the service life of bearings, especially in applications where they are subjected to constant friction and high loads.

Synergy between CNC Machining and Surface Treatments

The real magic happens when CNC machining and surface treatments converge. This synergy is beautifully illustrated in the production of a specialized bearing for a high-speed railway project. The bearing’s components were first precision-machined using advanced CNC technology. Following this, a multi-layered coating process was applied, involving ceramic and titanium compounds to withstand the extreme conditions of high-speed rail operations. This dual approach ensured that the bearings could endure high speeds and temperatures while maintaining superior performance.

Case Studies: Success Stories in Bearing Solutions

One notable case involves a renowned wind turbine manufacturer that faced frequent bearing failures. By switching to bearings produced with a combination of precision CNC machining and a unique surface treatment involving a diamond-like carbon coating, they saw a dramatic reduction in maintenance needs and a significant increase in turbine uptime.

Challenges and Solutions in Precision Bearing Production

Despite the advancements, challenges persist in the precision bearing sector. Material inconsistencies, machining errors, and treatment inaccuracies can all compromise bearing integrity. Addressing these issues, a joint venture between a Chinese CNC service provider and a European surface treatment specialist led to the development of a proprietary quality control system. This system integrates real-time monitoring during CNC machining with post-treatment inspection, ensuring that each bearing meets strict standards.

Conclusion: The Future of Precision Bearings in Global Markets

As the demand for high-performance machinery and equipment continues to grow, the role of precision bearings, crafted through the artful integration of CNC machining and surface treatments, becomes increasingly crucial. This evolving landscape not only highlights China’s significant contributions to the field but also sets the stage for global advancements in mechanical engineering and manufacturing.

Other Articles You Might Enjoy

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…

- Revolutionizing CNC Machining for Complex Aerospace Assemblies

Introduction to CNC Machining in Aerospace Assemblies Computer Numerical Control (CNC) machining represents a significant technological development playing a notable role in the creation of complex aerospace assemblies. CNC machining…