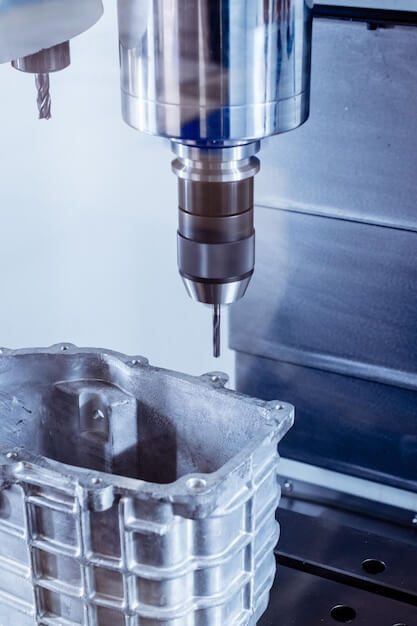

In modern industrial production, CNC (Computer Numerical Control) technology has become indispensable. With its characteristics of high precision, high efficiency, and high automation, CNC technology plays a crucial role in various fields. From automotive manufacturing to aerospace, CNC technology demonstrates its unique advantages and powerful capabilities.

Applications of CNC in the Automotive Industry Automotive manufacturing is one of the most extensive applications of CNC technology. Key components such as engines, chassis, and body parts rely on the high precision machining capabilities of CNC.

- Engine Materials: Engine cylinders and cylinder heads are typically made of gray cast iron and aluminum alloy. These materials require CNC machining to achieve strict dimensional and tolerance requirements, ensuring engine performance and longevity.

- Chassis Materials: The chassis includes key parts such as the transmission system, steering system, and braking system. These parts typically use high-strength steel and aluminum alloy. CNC machining ensures their complex shapes and high precision requirements.

- Body Materials: Body materials mainly consist of steel sheets and various types of steel. CNC technology plays a vital role in the cutting and forming of body parts.

Applications of CNC in the Machine Tool Industry Machine tool manufacturing also heavily relies on CNC technology, especially in the machining of high-precision and complex parts.

- Support Materials: Large and complex parts such as machine tool beds and bases are usually made of gray cast iron and nodular cast iron. CNC machining ensures high precision and complex shapes for these parts.

- Gear Materials: Transmission parts require high precision and strength. CNC machining meets these requirements and further improves gear performance through quenching and high-frequency induction hardening.

- Shaft Materials: High-strength steel shafts play a crucial role in machine tools. CNC machining ensures their rigidity, durability, and surface quality.

Applications of CNC in the Instrumentation Industry In the instrumentation industry, CNC technology is mainly used for manufacturing high-precision and small-sized parts.

- Housing Materials: Stainless steel, aluminum, brass, and plastics are commonly used for instrument housings and panels. CNC machining achieves precise machining and complex shapes for these materials.

- Shaft and Gear Materials: Shafts and gears in instruments require high precision and excellent mechanical properties. CNC machining ensures the high quality and reliability of these parts.

Applications of CNC in Thermal Equipment The manufacturing of thermal equipment such as boilers and steam turbines requires materials that can withstand high temperatures and pressures. CNC machining plays an important role in this regard.

- Boiler Materials: High-temperature resistant steels are the primary materials for boiler pipes and containers. CNC machining ensures their reliability and longevity in high-temperature environments.

- Steam Turbine Materials: Steam turbine blades and rotors are usually made of stainless steel and high-alloy steel. CNC machining achieves the complex shapes and high precision requirements of these parts.

Applications of CNC in Chemical Equipment The manufacturing of chemical equipment requires corrosion-resistant and high-strength materials. CNC technology excels in this area as well.

- Low Alloy Structural Steel: Used for pressure vessels and heat exchangers, low alloy steel requires precise machining. CNC technology ensures high precision and durability for these materials.

- Stainless Steel: Many parts in chemical equipment require stainless steel. CNC machining achieves the complex shapes and precision requirements of these parts.

- Non-Metallic Materials: Materials like ceramics and glass have high stability in corrosive environments. CNC technology enables precise machining of these materials.

Applications of CNC in Aerospace The aerospace industry demands extremely high requirements for materials and machining precision. CNC technology plays a crucial role in this field.

- High-Strength Steel: High-strength steel used for structural components in aircraft and spacecraft requires CNC machining to ensure strength and durability.

- High-Temperature Alloys: Nickel-based and other high-temperature alloys are used for aerospace engine components. CNC machining achieves the high difficulty and high precision requirements for these materials.

- Aluminum and Magnesium Alloys: These lightweight and high-strength materials are used for aircraft structures. CNC technology enables weight optimization and the production of high-strength parts.

- Composite Materials: Carbon fiber and glass fiber composites are used for various structural parts. CNC machining achieves their complex shapes and high precision requirements.

By integrating the above content, you can create a comprehensive and detailed article on CNC machining applications, showcasing the importance and advantages of CNC technology in different fields.

Related Posts

- High-Precision CNC Machining for Military Applications

Introduction to High-Precision CNC Machining in Military Applications The technical realm of high-precision Computer Numeric Control (CNC) machining is fast becoming integral to the military sector. This process, which relies…

- Precision CNC Machining for High-End Audio Equipment

Precision CNC Machining and its Role in High-End Audio Equipment Manufacturing The production of high-end audio equipment relies heavily on precision-driven processes to ensure the best quality sound. One such…

- Precision Aluminum CNC Machining: Cost-Effective Solutions for High-Volume Production?

Precision Aluminum CNC Machining: An Overview In the realm of manufacturing, precision aluminum CNC machining stands out as a key technique sought after for high-volume production runs. The term 'CNC'…

- The Art of CNC Precision Machining: Crafting High-Quality Parts

In the modern era, the success of CNC industries hinges on the production of parts that possess tight tolerances, impeccable surface finishes, and unwavering reliability. These meticulously crafted components contribute…

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Choosing the Correct Material for High-Precision CNC Gear Machining

Introduction: Understanding CNC Gear Machining and The Importance of Material Selection The precision in gear manufacturing largely depends on Computer Numerical Control (CNC) technology - a systematic procedure implemented to…