CNC (Computer Numerical Control) machining stands as a cornerstone in the world of manufacturing. It is an innovative technology that has revolutionized the entire spectrum of creating precise, quality and intricate details on substances varying from metal to plastic. One particular technique within this field that warrants attention is bead blasting.

Bead blasting is essentially a process where fine glass beads are blasted at a surface to give it a uniform, smooth, attractive finish with minimal abrasive damage. This non-destructive procedure aids in removing surface deposits by applying fine glass beads at high pressure without affecting the surface integrity. Grandly utilized during CNC machining processes, it possesses clear benefits over other traditional techniques.

Understanding the Bead Blasting Process

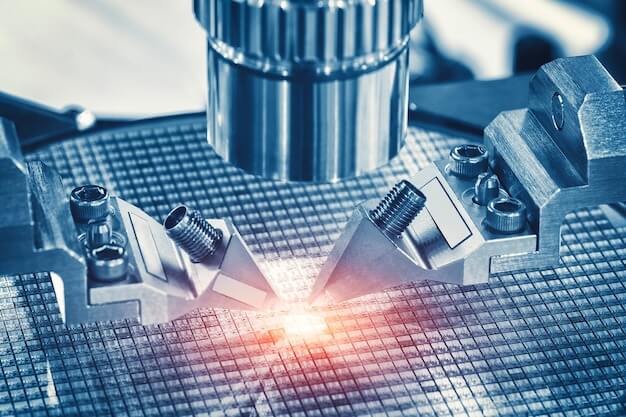

When put into action, bead blasting employs tiny spherical shots of glass propelled onto a surface under high pressure. The physical characteristics of these minuscule spheres allow them to provide a clean finishing touch while keeping the surface structure intact. Made possible through the use of various equipment such as air blast tumbling machines or even automated type sandblasting cabinets – ensure flexibility and increased efficacy for variety of components’ sizes and compositions.

A specific set of actions contribute towards successful completion of bead blasting within CNC machining; Starting off with choosing suitable glass bead size, confirming with the required thickness level of material to be removed. The blaster is then adjusted to a proper PSI level before executing the blasting operation. Multiple rounds can be performed if needed, cleaned up thoroughly afterwards to ensure no remnant cullet or broken glass interfere with subsequent operations.

Advantages of Bead Blasting in CNC Machining

This unique process provides myriad advantages contributing towards extreme productivity and desirable outcomes while undertaking CNC machining procedures. These include:

1. Non-Damaging: Since the process employs only small glass beads, the risk of damage to the machined part is significantly reduced. This in turn, increases the life span of the CNC machine as it has to undergo less strain.

2. Enhanced Aesthetics: Bead blasting is known for leaving a uniform finish on the surface with minimal scratches and defects. The finished product thereby boasts high aesthetic appeal making bead blasting indispensable for manufacture of products where appearance matters.

3. Versatility: Adaptable across an array of applications, from automotive parts to medical devices. It offers exceptional benefits over traditional methods like sand or grit blasting.

4. Competitive Edge: With superlative efficiency, impeccable aesthetics, and reduced impact damage, bead-blasted items can command higher market prices adding towards increased profitability.

Producing a Bead-Blasted Product

The production process of a bead-blasted item essentially involves the initial machining of the item using a CNC machine, subsequent finishing via bead blasting and concludes with inspection plus packaging stage. Skilled operators oversee each of these stages ensuring absolute precision adhering to stringent quality controls.

It’s notable that not all materials are suitable for bead blasting. Commonly metals like aluminium, stainless steel or titanium are preferred owing their susceptibility to receive significant visual enhancement besides maintaining functional integrity.

In conclusion, bead blasting represents a noteworthy innovation entrenched within CNC machining processes. Dependent upon immaculate blending of technology with skillful tactics, this technique promises capitalizing profit margins while retaining paramount focus onto producing optimum quality products. As we persist into deepening our technological prowess, such techniques continue to deliver immense value reinforcing belief – the future of manufacturing, indeed remains bright and promising.

Related Posts

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Exploring Bead Blasting in CNC Machining(cnc machining services china Nicole)

Bead blasting is a process used extensively in the world of computer numerical control (CNC) machining. A standard part of many businesses, bead blasting enriches various products that we use…

- Understanding Bead Blasting in CNC Machining(china machining Avery)

Bead blasting, a compelling term in the world of Computer Numerically Controlled (CNC) machining, is an influential process that plays a transformative role in optimizing and enhancing parts' aesthetic and…