Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to irreplaceable components utilised in automotive and medical devices—the seamless integration of bead blasting into CNC operations offers exceptional outcomes.

To understand the intricacies of bead blasting in the context of CNC machining, let’s start by defining what these terms imply.

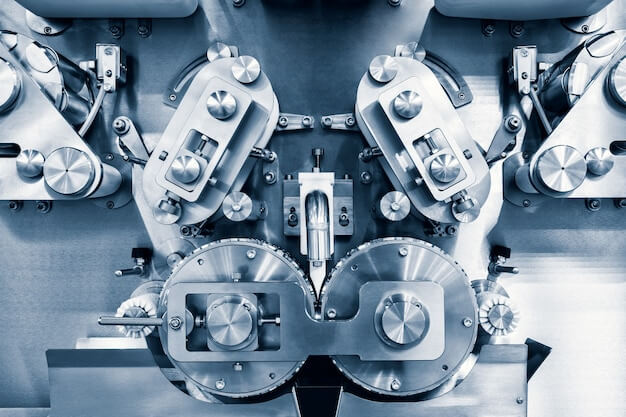

Computer Numerical Control or CNC refers to pre-programmed software dictating the movement of factory tools and machinery. It offers unparalleled control, precision, and adaptability which is paramount in today’s manufacturing landscape.

Bead blasting, on the other hand, is an abrasive cleaning technique that involves propelling tiny beads through a high-pressure system onto surface materials. This can strip away undesired material layers, smoothen out surfaces or provide a unique texture—ultimately enhancing the final product’s aesthetics.

Now, let’s delve deeper into how the bead blasting process is integrated in CNC machining.

1. Material Preparation

The initial step requires adequate preparation of the material. Depending on specifications set forth by design plans, CNC machinists decide the optimal course of action—this could vary from simple cleaning procedures to intricate drilling processes.

2. Conducting Bead Blasting

Following this, the bead blasting process begins. Tiny glass beads are shot at a high pressure towards the material’s surface. The intensity depends largely on the desired end-result; more aggressive blasting can significantly change the component’s appearance, while softer blasts merely polish its exterior.

3. Continuation of CNC Processes

Once bead blasting is complete, further necessary CNC processes are carried out. These could include detailed milling, turning, shaping amongst others. At every stage, checked and rechecked ensures consistent accuracy and adherence to specifications.

4. Final Inspection and Deliverance

After all procedures are complete, a comprehensive quality inspection is carried out. Once the product meets set standards, it’s packaged safely for transportation to clients or directly into assembly lines.

Bead blasting as part of the CNC machining sequence provides numerous benefits. These range from functional (increased durability, stress resistance) to purely aesthetic (enhanced texture, professional finish). Moreover, directing through software eliminates human error and increases efficiency—making high-volume production runs feasible without decreasing quality levels.

Given these advantages and the rise of industries relying on precision components globally, bead blasting within CNC machining has enormous potential in the future. However, several factors need consideration when choosing the right machining service provider that employs bead blasting techniques.

The chosen facility must possess state-of-the-art equipment and reliable protective measures ensuring operator safety during intense blasting phases. Additionally, their workforce should consist of certified professionals who understand the intricacies of bead blasting and can adapt to varying client requirements. Lastly, time-efficiency, consistency, and cost-effectiveness shouldn’t be compromised at any stage.

Conclusively, bead blasting within CNC machining is more than just an embellishing procedure—it maps the pathway towards creating sturdy, visually appealing, and dependable products across various sectors. With upcoming technological advancements, and finer expertise, greater heights will undoubtedly be achieved in this field.

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Custom CNC Machining for High-Quality Lighting Fixtures

Introduction to Custom CNC Machining For High-Quality Lighting Fixtures In this article, we aim to explore the integral role of custom Computer Numerical Control (CNC) machining in the production of…

- Exploring Bead Blasting in CNC Machining(cnc machining services china Nicole)

Bead blasting is a process used extensively in the world of computer numerical control (CNC) machining. A standard part of many businesses, bead blasting enriches various products that we use…