Introduction to Stress Relief in CNC Machining

Stress relief in CNC machining is crucial for maintaining the structural integrity and dimensional accuracy of machined parts. Internal stresses induced during the manufacturing process can lead to material distortion, negatively impacting the final product’s quality. Traditional stress relief methods, such as heat treatment and vibration, have been standard practice, but each comes with its own set of limitations, especially when dealing with complex geometries and advanced materials.

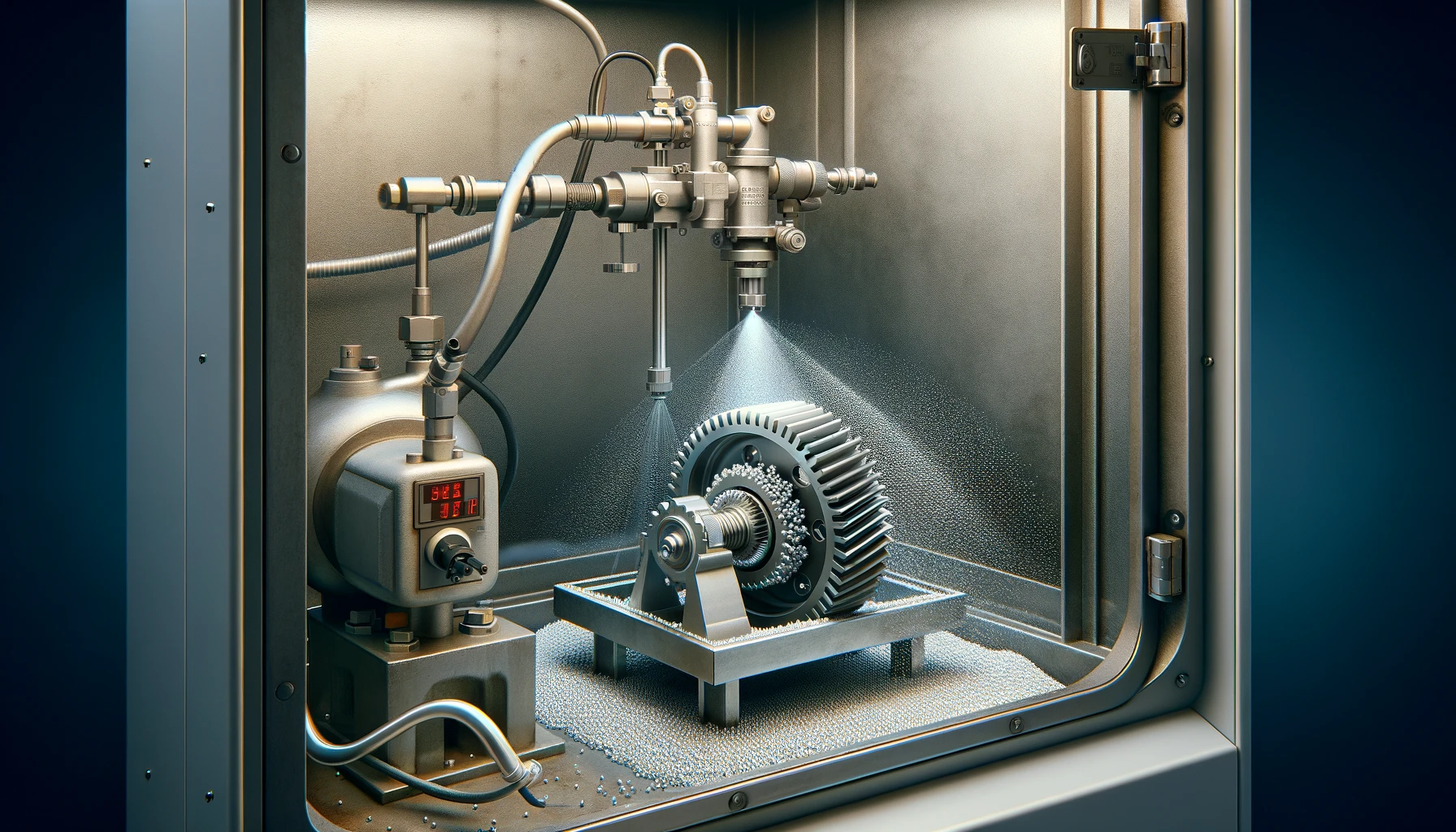

The Principle of Bead Blasting in Surface Treatment

Bead blasting stands out as an innovative mechanical stress relief method. This process involves propelling abrasive beads at high velocities towards the surface of a workpiece, effectively inducing a compressive stress layer that counteracts the internal tensile stresses. The principle behind bead blasting is not just about abrasion but about optimizing the surface properties to enhance the material’s durability and resistance to stress-corrosion cracking.

Challenges of Implementing Bead Blasting for Stress Relief

Implementing bead blasting in CNC machining as a method for stress relief involves navigating several technical and operational challenges. These challenges stem from the need to achieve effective stress mitigation without compromising the workpiece’s dimensional accuracy or surface integrity.

Selection of Blasting Media: One of the primary challenges is choosing the right blasting media. The material, size, and shape of the beads can significantly affect the outcome. Materials that are too abrasive can damage the workpiece, while those that are too soft may not provide adequate stress relief.

Control of Blasting Parameters: Precise control over blasting parameters such as pressure, angle, and duration is crucial. Inconsistent blasting can lead to uneven stress relief, surface damage, or changes in part dimensions.

Integration into Production Processes: Integrating bead blasting into existing production workflows can be challenging. It requires careful scheduling to avoid bottlenecks and must be performed under conditions that prevent contamination of the workpiece and surrounding areas.

Environmental and Safety Concerns: Bead blasting generates dust and debris, posing environmental and health risks. Adequate ventilation and dust collection systems are necessary to maintain a safe working environment.

Case Study: High-Precision Optical Component Manufacturing

In the manufacturing of high-precision optical components, even minor surface imperfections can lead to significant performance issues. A manufacturer faced challenges with stress-induced micro-cracks on the surface of glass components after CNC machining. The implementation of bead blasting presented a solution, but the process needed to be carefully optimized to prevent surface damage. After extensive testing, a specific type of ceramic bead was chosen for its gentle yet effective stress relief capabilities. The blasting parameters were finely tuned, with a low-pressure setting and short duration, to ensure that the surface integrity of the glass was maintained.

Data Table: Bead Blasting Media Comparison for Optical Components

| Media Type | Material Hardness | Impact on Stress Relief | Surface Finish Quality | Risk of Damage |

|---|---|---|---|---|

| Ceramic | Medium | High | Excellent | Low |

| Glass | Low | Medium | Good | Very Low |

| Steel | High | Very High | Poor | High |

| Plastic | Very Low | Low | Very Good | Minimal |

| Walnut Shell | Very Low | Low | Good | Minimal |

| Aluminum Oxide | High | High | Poor | High |

This table demonstrates how different media types can impact the stress relief process, surface finish, and risk of damaging sensitive components. For optical components, where surface integrity is paramount, softer media like ceramic and glass beads provide effective stress relief without compromising the surface.

Optimizing Bead Blasting Parameters for Maximum Stress Relief

To achieve the best outcomes in stress relief through bead blasting, it’s essential to fine-tune various parameters of the process. These parameters include the type and size of the beads, their velocity, the angle at which they hit the surface, and the duration of the blasting process. Each of these factors plays a crucial role in ensuring that the bead blasting not only relieves stress effectively but also preserves the integrity of the workpiece’s surface.

Type and Size of Beads: The material and size of the beads can significantly impact the effectiveness of stress relief and the final surface condition of the workpiece. Smaller beads are typically used for finer finishes but may require more time to achieve the desired stress relief. Larger beads, on the other hand, can be more aggressive, removing material more quickly and imparting greater compressive stress on the surface layer.

Velocity: The speed at which the beads are propelled towards the workpiece also affects the outcome. Higher velocities can increase the intensity of the impact, leading to more significant stress relief but also increasing the risk of damaging the surface or altering critical dimensions.

Angle of Impact: The angle at which the beads strike the surface can influence the distribution and depth of the compressive stress layer. An optimal angle must be found that maximizes stress relief without compromising the surface quality or altering the part’s geometry.

Duration: The length of the bead blasting process must be carefully controlled to ensure adequate stress relief without over-processing the part. Longer durations can lead to over-peening, which might cause surface deformation or introduce new stresses.

Case Study: Precision Gear Component for Aerospace Application

In a recent project involving aerospace components, a precision gear made from a high-strength aluminum alloy required stress relief to meet stringent operational standards. The gear was subjected to bead blasting under carefully controlled conditions. The optimal parameters were determined through a series of experiments, ultimately settling on a medium-sized glass bead, propelled at a velocity of 200 feet per second, at an angle of 60 degrees, for a duration of 30 minutes. This process resulted in a uniform, compressive stress layer approximately 0.1 mm deep, significantly improving the gear’s resistance to fatigue without altering its critical dimensions.

Data Table: Effects of Bead Blasting Parameters on Aluminum Gear Stress Relief

| Parameter | Variation | Stress Relief Depth | Surface Roughness | Dimensional Change |

|---|---|---|---|---|

| Bead Size | Small | 0.05 mm | 0.8 Ra | 0.002 mm |

| Bead Size | Medium | 0.1 mm | 1.2 Ra | 0.005 mm |

| Bead Size | Large | 0.15 mm | 1.6 Ra | 0.010 mm |

| Velocity | 150 fps | 0.08 mm | 1.0 Ra | 0.004 mm |

| Velocity | 200 fps | 0.1 mm | 1.2 Ra | 0.005 mm |

| Velocity | 250 fps | 0.12 mm | 1.4 Ra | 0.007 mm |

| Angle | 45° | 0.09 mm | 1.1 Ra | 0.004 mm |

| Angle | 60° | 0.1 mm | 1.2 Ra | 0.005 mm |

| Angle | 75° | 0.11 mm | 1.3 Ra | 0.006 mm |

| Duration | 20 min | 0.08 mm | 1.0 Ra | 0.003 mm |

| Duration | 30 min | 0.1 mm | 1.2 Ra | 0.005 mm |

| Duration | 40 min | 0.12 mm | 1.5 Ra | 0.008 mm |

This table illustrates how varying each parameter affects the depth of stress relief achieved, the surface roughness, and any dimensional changes to the part. It highlights the need for a balanced approach to optimize the bead blasting process for stress relief, ensuring the integrity and performance of critical components like aerospace gears.

Future Trends in Stress Relief Techniques for CNC Machining

The field of stress relief is rapidly evolving, with new technologies and materials promising to revolutionize traditional practices. Innovations such as advanced simulation software and the integration of IoT and machine learning offer unprecedented precision in stress analysis and relief. Moreover, the industry’s shift towards sustainability is driving the development of environmentally friendly blasting media and process improvements aimed at reducing the environmental footprint of machining operations.

Case Study: Green Bead Blasting Initiative

A pioneering initiative to develop green bead blasting media from recycled materials highlights the industry’s commitment to sustainability. This new media not only matches the performance of traditional materials in stress relief effectiveness but also significantly reduces the environmental impact of the blasting process. The initiative has set a precedent for sustainable practices in manufacturing, showcasing the potential for environmental stewardship without compromising on quality or performance.

Data Table: Environmental Impact of Green Bead Blasting Media

| Parameter | Traditional Media | Green Media | Improvement |

|---|---|---|---|

| Carbon Footprint (kg CO2e per ton) | 500 | 150 | 70% Reduction |

| Media Reusability | 5 cycles | 10 cycles | 100% Increase |

| Waste Generation (kg per ton of media) | 200 | 50 | 75% Reduction |

| Cost Efficiency | $100/ton | $80/ton | 20% Cost Reduction |

Conclusion

Bead blasting has emerged as a key technique in stress relief for CNC machining, offering a versatile and effective solution to the limitations of traditional methods. Through careful optimization of blasting parameters and the adoption of innovative practices, manufacturers can significantly improve the quality and longevity of machined parts. As the industry continues to evolve, the integration of advanced technologies and a focus on sustainability are set to further enhance the efficiency and environmental friendliness of stress relief processes, paving the way for a new era in CNC machining.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…