Introduction to Precision CNC Machining

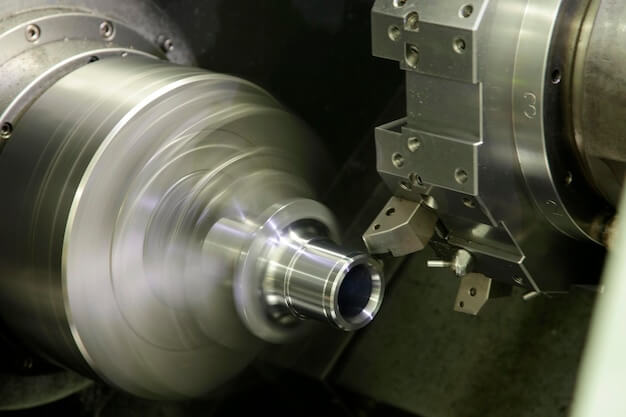

Precision CNC (Computer Numerical Control) machining is a globally adopted process used in the manufacturing sector that involves the use of computers to control machine tools. From milling machines, lathes, to laser cutters—precision CNC machining helps businesses simplify complex cutting tasks into simple numeric control directives executed with utmost precision.

The importance of this technological advancement has touched every aspect of industry operations. However, its significance is particularly profound within the aerospace industry, where precision and reliability can never be compromised. Aerospace components like turbine blades or aircraft frameworks demand stringent tolerance requirements which only advanced processes like precision CNC machining can accomplish.

- Milling machines: These are often operated by CNC technology for creating shapes and slots in metal parts. In aerospace, they help create precise engine components.

- Lathes: Mostly used for precisely cutting symmetrical parts, these are crucial for manufacturing cylindrical aerospace parts.

- Laser cutters: For high-accuracy cutting of gears and other intricate parts, space craft manufacturers heavily rely on CNC-based laser cutters.

Understanding Aerospace Titanium Parts

In the aerospace industry, titanium is a crucial material used in its operations due to its unique properties. It is known for its high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures among other notable characteristics. These attributes make it especially suitable for fabrication of various parts deployed in aircrafts.

- The engine: Due to titanium’s heat-resistant property, it is used for constructing critical engine components capable of withstanding high operating temperatures.

- Airframe structures: The lightweight but strong characteristics of titanium qualify it as an ideal component for manufacturing airframes, enabling enhancement of fuel efficiency and overall performance of the aircraft.

- Landing gears: Given the enormous weight these components carry during landing and liftoff, they are often made from titanium owing to its superior strength and durability.

This is merely a snapshot of where titanium finds application within the scope of aerospace production, a testimony to its unmatched versatility and resilience.

Role of Precision CNC Machining in Manufacturing Aerospace Titanium Parts:

- Precision CNC machining plays a crucial role in manufacturing aerospace titanium parts, ensuring the high level of precision required in the aerospace industry is met. It allows for the production of complex and intricate titanium components that meet industry standards and exceed expectations.

- Service Provider: When seeking a precision CNC machining manufacturer for aerospace titanium parts, it is essential to partner with a reliable Precision Machining Service that offers expertise in aerospace titanium machining and proven capabilities in manufacturing high-quality titanium parts.

Choosing a Manufacturer for Aerospace Titanium Parts

When selecting a manufacturer for aerospace titanium parts, there are several factors to consider. It can be likened to an airline searching for the right partner to produce complex and high-precision turbine blades. Primary considerations may include technological capability, quality assurance systems, production capacity, and industry reputation. Examining these criteria helps ensure that the chosen company possesses the necessary infrastructure and expertise.

- Technological Capability: The manufacturer should employ precision CNC machinery capable of handling the intricate maneuvers required in working with aerospace-grade Titanium.

- Quality Assurance Systems: Given the critical performance demand of the aerospace sector, it is essential to opt for manufacturers with robust quality assurance protocols.

- Production Capacity: Choose a manufacturer who will not only meet current production needs but also scale up as your requirements grow.

- Industry Reputation: Lastly, researching previous partnerships and clients will furnish insights into a potential manufacturing partner’s reliability and track record.

Besides these valuable factors, working with a manufacturer boasting extensive knowledge and experience in CNC machining carries importance. Such manufacturers possess invaluable insight into overcoming challenges associated with crafting intricate yet resilient titanium parts — delivering on tight tolerances while maintaining structural integrity. Consequently, they can deliver superior results consistently and efficiently.

Future Innovations in Precision CNC Machining

The sphere of precision CNC machining for aerospace titanium parts is poised for significant technological advancements. Cutting-edge innovations may involve heightened automation, software enhancements, greater material diversity as well as the evolution of more potent additive manufacturing processes.

- Automation: The adoption of advanced robotics and artificial intelligence in CNC machining can streamline production workflows, reducing time lags and improving accuracy.

- Software Enhancements: Future software upgrades aim to bridge gaps between design and fabrication phases. This synchronization can lead to the reduction of errors and ultimately, a higher quality finish for titanium components.

- Material Diversity: As research continues to evolve in this field, we could soon be utilizing new alloys that offer increased strength-to-weight ratios or better resistance to extreme temperatures – important factors for aerospace applications.

- Additive Manufacturing: Often referred to as 3D printing, this technology is already revolutionizing industries across the board with its potential for producing complex structures cost-effectively. In terms of aerospace components, it opens up possibilities such as quicker turnaround times and even on-demand part production.

All these advancements combined stand to expedite the manufacturing process, improve efficiency while maintaining stringent industry safety standards when creating aerospace-grade titanium parts.

Other Articles You Might Enjoy

- The Role of Bead Blasting in CNC Machining (bead blasting Steward)

Bead blasting is a commonplace aspect of numerous manufacturing procedures, including Computer Numerical Control (CNC) machining. Whether it's to enhance the external aesthetics or improve internal functionalities, bead blasting plays…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…