Introduction to CNC Machining and Its Challenges

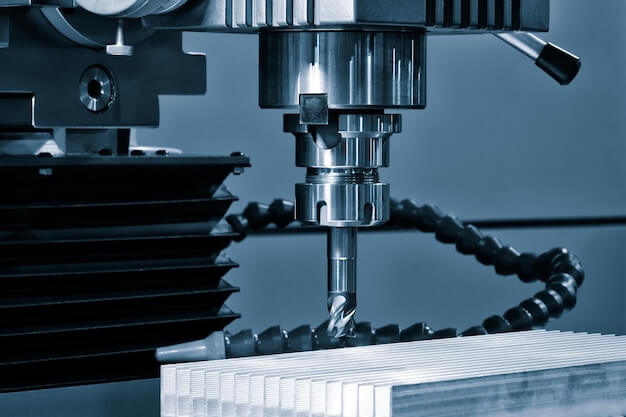

CNC (Computer Numerical Control) machining is a critical process in manufacturing, enabling precise, efficient production of complex parts. It plays an integral role in numerous industries including automotive, aerospace and medical by facilitating the mass manufacture of high-precision components. However, multiple challenges commonly confront CNC operations.

- Material hardness: Some metals and alloys are so hard that they significantly reduce tool life and slow down the cutting speed, limiting productivity.

- Thermal stability: Many materials’ properties alter at high temperatures generated during milling or drilling which leads to deformation or loss of tolerance.

- Surface finish: Achieving acceptable surface finishes on certain materials can be difficult due to their specific mechanical properties.

Innovations in material science such as advanced metal alloys and plastics offer promising solutions to these issues, potentially revolutionising CNC machining processes for improved efficiency and product quality.

Understanding the Role of Material Science in CNC Machining

The fundamental principle behind material science involves investigating the structures and properties of materials. This multi-disciplinary field that explores such aspects as metals, ceramics, polymers and composite materials is a cornerstone in modern manufacturing processes involving Computer Numerical Control (CNC) machining. By understanding the characteristics of both Metal Alloys and Plastics through the lens of material science, technologists can anticipate capabilities and limitations regarding their machinability, strength, conductivity, corrosion resistance among other traits helping to optimize CNC machining operations for increased efficiency and product quality.

- For instance, denser and harder alloys require robust machines capable of exerting more force while maintaining high precision during the production.

- In contrast, softer plastics necessitate control over heat generation during machining because an elevated temperature might burn or warp the workpiece.

- This underscores material science’s significance in selecting suitable toolpaths or making necessary adjustments in parameters like feed rates, speeds, coolant application among others informed by the selected WorkPiece Material (WPM).

Addressing Challenges with Innovations in Metal Alloys

When it comes to CNC machining, addressing challenges with innovations in metal alloys is crucial for achieving optimal results. Here is a step-by-step analysis of how material science is driving advancements in metal alloys:

1. Understanding Material Properties:

- Material science plays a vital role in understanding the properties of different metal alloys.

- By studying the composition, structure, and behavior of metals, scientists can develop innovative alloys with enhanced properties.

- Understanding material properties is essential for addressing challenges in CNC machining and optimizing performance.

2. Tailoring Alloys for Specific Applications:

- Advancements in material science allow for the tailoring of metal alloys to meet the specific requirements of CNC machining applications.

- By adjusting the composition and processing techniques, alloys can be optimized for factors such as strength, hardness, corrosion resistance, and thermal conductivity.

- This customization enables CNC machinists to overcome challenges and achieve desired outcomes.

3. Improving Machinability:

- Machinability is a critical factor in CNC machining, and innovations in metal alloys aim to improve this aspect.

- New alloys are being developed with enhanced machinability characteristics, such as reduced tool wear, improved chip control, and increased cutting speeds.

- These advancements help address challenges related to machining efficiency and productivity.

4. Enhancing Material Performance:

- Material science innovations focus on enhancing the performance of metal alloys in CNC machining.

- By incorporating elements or modifying the microstructure, alloys can exhibit improved mechanical properties, heat resistance, electrical conductivity, and other desirable characteristics.

- These advancements enable CNC machinists to overcome challenges related to part durability, thermal management, and electrical performance.

Addressing challenges in CNC machining through innovations in metal alloys is an ongoing process driven by material science. By understanding material properties, tailoring alloys for specific applications, improving machinability, and enhancing material performance, CNC machinists can overcome challenges and achieve superior results. To leverage these advancements and access professional CNC machining services, you can rely on our online CNC service or precision machining service.

Solving Issues Through Advanced Plastics

Traditional plastics have presented a number of challenges in CNC machining processes. Difficulties often arise due to their low melting point and malleability, making them susceptible to deformation during machining. Furthermore, conventional plastics tend to be less durable under significant stress which can lead to premature wear and tear.

Nonetheless, advancements in plastic materials science provide the potential solutions to these issues. Enhanced thermo-stable plastics have an improved heat resistance capacity that reduces the risk of deformation or burning during the machining process. Moreover, modern plastics like highly-engineered thermoplastics demonstrate superior strength and durability compared to traditional counterparts. These innovative materials offer higher impact resistance and dimensional stability while being machined.

To illustrate, consider Polyether ether ketone (PEEK), one of the latest advances in engineering plastics suitable for CNC machining. Its exceptional thermal stability, excellent mechanical properties, and chemical resistance significantly enhances CNC machining performance. In practical terms, when PEEK was used in creating automotive parts, it impressively withstood high-speed operations without losing its shape or experiencing warp – an issue commonly experienced with conventional plastics.

The Future of Materials Science in CNC Machining

Materials science stands at the cusp of an exciting future paving way for substantial advancements and innovations that cater to incredible transformations in CNC machining. The upcoming trends hint towards the emergence of ‘smart’ materials, like shape-memory alloys and self-healing polymers, capable of altering their properties in response to external stimuli. In addition, innovations such as micro-lattice structures can offer strength along with considerably low weight, changing the game for industries where every gram matters.

These developments hold promise impact in streamlining CNC processes by presenting enhanced tool life due to lower wear rates, increased manufacturing speed, improved surface finish and overall enhancement in machining efficiency. For instance, using a shape-memory alloy could ease the process of intricate design formation through simpler cutting paths while providing high durability.

- ‘Smart’ Materials: Shape-memory alloys and self-healing polymers are expected to revolutionize the CNC machining landscape by adaptively adjusting physical conditions to facilitate efficient production methods.

- Micro-Lattice Structures: Offering high-strength yet lightweight solution, these novel structures will be instrumental in applications where weight management is critical thus increasing competitiveness in aerospace and automotive sectors.

- Enhanced Tool Life: Material innovations minimize wear rate which translates to longer tool life, reducing frequent changeovers and associated downtime enhancing productivity and cost-efficiency.

Other Articles You Might Enjoy

- From Concept to Reality: Material Prototyping Challenges in CNC Machining

Introduction to CNC Machining and Material Prototyping CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated creation of parts from various materials.…

- Advancements in Material Science: Impact on CNC Machining Techniques and Outcomes

Introduction to Material Science and CNC Machining Material science plays a pivotal role in manufacturing by studying the properties and applications of various materials, such as metals, polymers, ceramics, and…

- Challenges posed by material ductility in CNC machining

Understanding Material Ductility in CNC Machining In the realm of Computer Numerical Control (CNC) machining, where precision and accuracy are paramount, material ductility represents a significant factor influencing the quality…