Chapter 1: Introduction

If you’ve ever held a carbon fiber case, you probably noticed how ridiculously light it feels—yet somehow, it feels tougher than metal. That’s not just a gimmick. Carbon fiber offers a unique combo: aerospace-grade strength with feather-light weight. When combined with the precision of CNC machining, it becomes a dream solution for crafting sleek, durable, and high-performance custom enclosures.

So why this manual? I’ve been hands-on with carbon fiber CNC work for years—everything from drone shells to rugged phone cases—and I realized there’s no real, no-nonsense guide that breaks down how to go from carbon fiber sheet to a finished CNC-machined enclosure. That’s what this is.

This manual isn’t just technical theory. It’s field-proven advice. I’ll walk you through the materials, the machine setups, the design decisions, and even the unexpected problems you’ll hit—like delamination or carbon dust going everywhere (been there).

If you’re a product designer, engineer, startup founder, or even a maker trying to DIY your own carbon fiber case, this guide is for you. I’ll also include real-life tips, a couple supplier lists, and two solid data tables that’ll save you hours of research.

Throughout this article, I’ll use the phrase “carbon fiber case” consistently and deliberately. Why? Because that’s what you came for—and that’s what we’re covering in depth.

Chapter 2: Understanding Carbon Fiber Sheet Materials

Before cutting anything, we need to understand what we’re cutting. If you’re designing or sourcing a carbon fiber case, you’re probably looking at carbon fiber sheets as your starting point. And not all carbon fiber sheets are created equal.

I’ve tried different types: glossy, matte, woven, forged, you name it. Some are a joy to machine—others? Not so much.

What Exactly Is Carbon Fiber?

Carbon fiber is made from strands of carbon atoms bonded into a crystalline structure. When embedded in a resin matrix, these fibers become a composite material that’s incredibly strong for its weight.

It’s not metal. It’s not plastic. It’s in a class of its own. That’s why carbon fiber cases feel so unique.

Types of Carbon Fiber Sheets

There are several types of sheets available for CNC machining. Here’s a breakdown of what I’ve worked with:

1. Woven Carbon Fiber Sheet (Twill or Plain Weave)

- Great for aesthetics—visible weave patterns

- Decent strength in two directions

- Easy to find, easy to cut

2. Forged Carbon Fiber

- Made from chopped fibers compressed in resin

- Randomized patterns (some love it, some hate it)

- More isotropic strength, but less surface consistency

3. Prepreg Carbon Fiber

- Pre-impregnated with resin

- Needs baking (autoclave or oven)

- Expensive and typically used in aerospace or F1

4. Hybrid Sheets (Carbon-Kevlar, Carbon-Glass)

- Adds impact resistance

- Looks cool (yellow/blue threads with black carbon)

- Slightly harder to machine cleanly

Glossy vs Matte Surface

For CNC-cut carbon fiber cases, I usually go with matte twill sheets. Glossy finishes look stunning but are harder to finish cleanly without edge chipping.

Thickness Options

The most common sheet thicknesses for carbon fiber case design are:

| Application | Recommended Thickness |

|---|---|

| Smartphone / Tablet Case | 1.0mm – 1.5mm |

| Laptop / Notebook Enclosure | 1.5mm – 2.5mm |

| Drone/RC Chassis Components | 2.0mm – 3.0mm |

| Structural Housing (e.g. control box) | 3.0mm – 5.0mm |

| Decorative Plates / Covers | 0.5mm – 1.0mm |

| Wearables / Thin Skins | 0.3mm – 0.5mm |

Material Performance Table

Here’s how common carbon fiber sheet types compare:

| Property | Woven CF (Twill) | Forged CF | Prepreg CF | Hybrid CF |

|---|---|---|---|---|

| Machinability | ✅ Easy | ⚠️ Moderate | ❌ Difficult | ⚠️ Moderate |

| Strength (in-plane) | ✅ High | ✅ High | 🔥 Extremely High | ✅ Good |

| Surface Finish | ✅ Clean | ⚠️ Uneven | ✅ Clean | ⚠️ Mixed |

| Availability | ✅ High | ✅ Moderate | ❌ Limited | ✅ Moderate |

| Cost per Sheet (USD) | ~$25–$70 | ~$35–$90 | $100+ | ~$40–$80 |

My Recommendation

For most carbon fiber case projects, go with:

- 1.5mm matte twill sheet for phones/tablets

- 2.5mm twill or forged for laptops, drones, or structural covers

Avoid prepreg unless you have experience or an autoclave. And hybrids? Cool, but can fray easily.

Chapter 3: Preparing for CNC Machining

So you’ve picked your carbon fiber sheet—great. Now, let’s talk about getting your CNC setup ready. This chapter might not be glamorous, but trust me, prep work is half the battle when machining a carbon fiber case. If your shop isn’t dialed in, your parts will suffer—or worse, your lungs will.

Required CNC Machine Capabilities

You don’t need a five-axis $100K beast to machine a carbon fiber case. But you do need a machine that checks a few important boxes.

Minimum Specs I Recommend:

- Spindle Speed: 10,000–30,000 RPM (higher is better)

- Work Area: At least 300mm x 300mm for mid-size enclosures

- Z Clearance: 50mm or more, depending on jig height

- Control Software: Any that supports standard G-code (Mach3, GRBL, etc.)

I’ve personally used everything from a Shapeoko Pro to a Tormach 770M. Both handled 2mm carbon fiber well—just don’t cheap out on the spindle.

Tooling: Endmills and Coatings

Carbon fiber eats tools for breakfast. It’s abrasive, and the wrong bit will dull fast and leave jagged edges.

Tool Checklist:

- Tool Type: Solid carbide (double-flute or diamond-cut)

- Coating: TiAlN or Diamond-Like Coating (DLC)

- Diameter: 1.5–3.0mm for most fine work

- Length of Cut: Just long enough—too long = chatter

Always keep spares. I burn through bits every 3–4 panels when cutting tight inner corners.

Dust Collection and Safety

Here’s the part that gets real. Carbon fiber dust isn’t just messy—it’s toxic to your lungs and conductive, meaning it can short electronics.

What You Need:

- A full enclosure around your CNC machine

- Shop vac or extraction system with a HEPA filter

- Anti-static hose and ducting

- Personal PPE: N95 mask or P100 respirator, safety glasses, gloves

I once skipped the respirator during a “quick job.” Never again. My throat felt like sandpaper for two days.

Workholding: Fixturing for Carbon Fiber Sheets

Carbon fiber is thin and stiff—it doesn’t want to lay perfectly flat. You’ll need to secure it well.

Best Options:

- Double-sided tape (strong kind used in PCB milling)

- Vacuum table (if you’re doing batches)

- Fixture plate with clamps + sacrificial layer (like MDF)

Avoid over-clamping—carbon can crack under uneven stress.

Coolant? No Thanks

You don’t use coolant when cutting carbon fiber. It doesn’t conduct heat like metal, and adding coolant makes cleanup harder and might even damage the sheet’s finish.

Quick CNC Setup Summary Table

| Component | Recommendation |

|---|---|

| CNC Machine | 10k–30k RPM, rigid frame, >300mm work area |

| Endmills | Solid carbide, DLC/TiAlN coating, 1.5–3mm diameter |

| Dust Collection | HEPA-grade vacuum + enclosure |

| Personal Safety Gear | N95/P100 mask, gloves, safety glasses |

| Workholding | Tape, vacuum table, or clamped fixture plate |

| Coolant Usage | Not recommended |

| Maintenance Note | Change bits often; inspect belts and collets regularly |

Chapter 4: Step-by-Step CNC Machining Workflow

This is where everything comes together. If you’ve got your sheet, your tools, your machine, and your shop setup dialed in, it’s time to actually make the carbon fiber case.

I’ve broken this chapter down into real-world steps. No theory—just what I’ve done over dozens of custom enclosure projects. The goal: help you go from .STEP file to a clean, usable carbon fiber case with zero guesswork.

Step 1: CAD Design and CAM Setup

Design Considerations

Start with your CAD model. Whether you’re using Fusion 360, SolidWorks, or FreeCAD, make sure your design respects carbon fiber’s limitations:

- Avoid small inside radii (<1mm)

- Use fillets on corners to reduce delamination risk

- Minimum wall thickness: 1mm

- Use slot widths that match your bit size to avoid multiple passes

CAM Strategy

In Fusion 360, I usually stick with these toolpaths:

- 2D Contour for outlines and cutouts

- Pocket for large internal areas

- Drilling if I need mount holes

Feed & Speed Baselines (for 2mm thick CF, using a 2mm DLC-coated bit):

- Spindle: 18,000 RPM

- Feed rate: 300–500 mm/min

- Stepdown: 0.2–0.4mm

- No coolant, no mist

Step 2: Fixturing and Setup

Here’s where most people mess up: the carbon fiber sheet must be perfectly flat and firmly secured. Warping mid-cut will ruin precision.

My Fixture Stack-Up

- MDF sacrificial board

- Double-sided tape (3M VHB or equivalent)

- Carbon fiber sheet

I check for flatness using a metal straight edge and dial indicator. Any flex = redo the taping.

Step 3: Toolpath Execution

This is the fun part, but don’t walk away. Carbon fiber can chip unpredictably.

Best Practices While Cutting:

- Start shallow: your first pass should skim to test adhesion

- Keep vacuum running at all times

- Watch for edge fray or burning

- Pause if you hear screeching—your bit’s probably dull

Step 4: Post-Processing and Finishing

Once cut, edges might be rough or frayed. Here’s my go-to process:

Deburring:

- Use 600–1000 grit sandpaper

- Always sand away from the fiber weave

- Use a mask—even this light sanding throws dust

Edge Sealing:

To protect from delamination and moisture:

- Wipe edges with isopropyl

- Apply thin epoxy layer or UV-hardened resin

Aesthetic Finish:

- Matte? Leave it as-is

- Glossy? Spray a few layers of clear coat, then polish

Common CNC Carbon Fiber Case Problems (and Fixes)

| Problem | Cause | Fix |

|---|---|---|

| Edge fray | Dull bit, wrong feed rate | Replace tool, slow feed |

| Delamination at corners | No fillets, deep plunge | Add fillets, reduce stepdown |

| Sheet shifting mid-cut | Weak fixture or uneven surface | Use better tape, flatten base |

| Burning or melted epoxy smell | Too slow feed / no dust extraction | Increase feed, improve airflow |

| Ragged holes | Wrong drill type or low RPM | Use single-flute drill or CNC mill |

When it works, it really works. A properly machined carbon fiber case looks like something out of a high-end aerospace lab. Lightweight. Sharp. Sturdy. If you’re doing client work, they’ll feel the difference immediately.

Chapter 5: Design Guidelines for Carbon Fiber Cases

Design is where most carbon fiber case projects succeed—or fail. I’ve seen beautiful CNC cuts wasted on designs that ignored basic material behavior. Carbon fiber isn’t metal, and it’s not plastic. You can’t treat it the same way.

This chapter walks through what works, what doesn’t, and what I’ve learned the hard way from failed prototypes and cracked panels.

Designing for Strength Without Overbuilding

Carbon fiber is extremely stiff, but that doesn’t mean it’s indestructible. If you design sharp corners or ultra-thin walls, you’ll get cracks or delamination—especially during CNC machining.

Golden Rules for Structural Design:

- Min wall thickness: 1.0mm (1.5mm preferred for screw holes)

- Avoid sharp internal corners: Use 1mm fillets minimum

- Rounded edges handle stress better than square ones

- For mounting holes, keep at least 3mm material around each side

Cutout and Slot Design Tips

A common mistake when designing cutouts (like USB ports or button holes) in a carbon fiber case is to undersize the features and overcomplicate geometry.

What Works:

- Slot widths should be 0.1mm larger than component tolerances

- Avoid sharp transitions—smooth them to reduce stress risers

- Use “dogbone” corners only if absolutely needed for fitting square parts

Mounting Methods

Mounting is the trickiest part of designing a carbon fiber enclosure. You want your case to open/close, hold together securely, and maybe even look cool doing it.

Here are your main options:

| Method | Pros | Cons |

|---|---|---|

| Screws + Brass Inserts | Strong, removable | Adds weight, needs careful spacing |

| Snap Fit | Tool-free, clean look | Not easy in carbon fiber, brittle risk |

| Adhesive Bonding | Seamless, light | Not serviceable |

| Magnets | Elegant, smooth closure | Requires internal support or nesting |

| Hinge + Clip | Great for toolboxes / remotes | Harder to CNC accurately |

My go-to is screws + inserts for anything functional, and magnets for display or lightweight use.

Surface Texture & Branding

Want your carbon fiber case to look premium? Texture matters.

Finishing Options:

- Matte sheet: No extra step, stays subtle and modern

- Gloss coat: Can be applied after machining; makes it “pop”

- Laser etching: Light logos possible, but be careful—burnt epoxy smells awful

- Vinyl overlays: Optional if you want color or grip

Pro tip: customers feel the quality more than they see it. Sanded or unfinished edges ruin that effect.

Thermal and Electrical Design Notes

Carbon fiber is:

- Thermally stable (but not a heatsink)

- Electrically conductive

This matters if your enclosure houses PCBs or anything powered.

Design Safeguards:

- Use nylon spacers under circuit boards

- Never route signal paths through carbon fiber alone

- Consider coating internal surfaces with resin or tape if there’s risk of shorts

Real-World Design Mistakes I’ve Made

| Design Error | Result | Lesson Learned |

|---|---|---|

| 90° corners on thin edges | Panel split during cut | Always add fillets |

| Tight fit on USB port | CNC kerf too small, cable didn’t fit | Add tolerance for tool width |

| No bracing in top shell | Flexed and cracked under pressure | Add inner ribs or thicker section |

| Used snap-fit clip idea | Tabs broke during install | Carbon’s brittle—don’t treat like ABS |

Design Checklist (Print or Save)

| ✅ Design Element | Status |

|---|---|

| Wall thickness ≥ 1mm | |

| Fillets added to internal edges | |

| Cutouts oversized by 0.1mm | |

| Screw spacing 3mm from edge | |

| Material modeled at correct thickness | |

| PCB mounting isolated from CF | |

| Surface finish defined |

Print this before sending a file to machining. It’s saved me more than once.

A carbon fiber case only performs well if it’s designed for how the material behaves. If you build like it’s metal, you’ll end up disappointed. Build like it’s carbon fiber, and you’ll get something that’s strong, lightweight, and absolutely badass.

Chapter 6: Application Examples & Template Ideas

Now that we’ve covered materials, machine setup, and design principles, let’s talk about what you can actually make. The term carbon fiber case might sound specific, but its use spans across industries—from consumer gadgets to aerospace gear.

Here, I’ll break down actual use cases I’ve either built myself or worked on with clients. I’ll also include template ideas that can speed up your prototyping and help you avoid reinventing the wheel.

Use Case 1: Smartphone or Tablet Carbon Fiber Case

This is probably the most searched-for type of carbon fiber case. And honestly? It’s where I started too. Lightweight, cool-looking, and durable—what’s not to like?

Design Notes:

- Stick with 1.0–1.5mm thickness for minimal bulk

- Use rounded corners and chamfered edges for comfort

- Include small holes for button feedback or hinge clips

Challenges:

- Ensuring wireless signal pass-through (carbon fiber can block it)

- Snap-fit clips often fail—use magnets or screws

Use Case 2: Laptop Shell or Custom Tech Housing

I’ve done a couple of carbon fiber laptop shells for field engineers—think toughbook-style, but sexy.

Design Notes:

- Thickness: 2.0–2.5mm

- Add reinforcing ribs on large panels to prevent flex

- Include embedded brass inserts for USB, HDMI, etc.

Finish Tip:

- Matte twill looks modern and doesn’t show fingerprints

- CNC your logo into the lid and seal with UV resin for branding

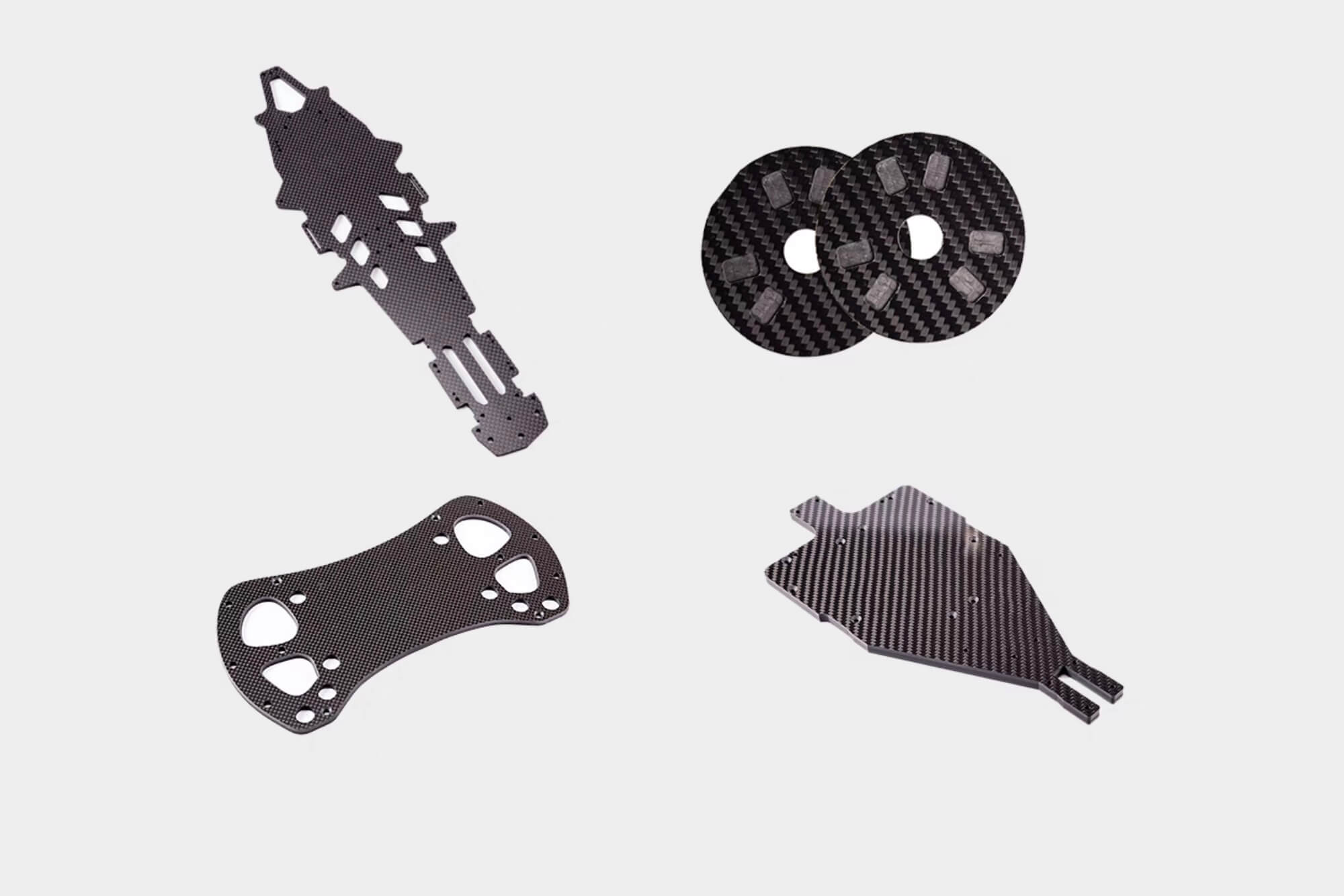

Use Case 3: Drone Frames & Remote Controller Cases

This one’s big. Drones are obsessed with strength-to-weight ratio, which makes carbon fiber cases the go-to.

For Frames:

- Go up to 3.0mm thickness

- Use dense bolt pattern to prevent vibration

- Weight savings matter more than cosmetics here

For Controllers:

- Use 2-part clamshell designs

- Include panel mounting spots for toggle switches

I worked with a team building FPV drone parts—every gram counted. Carbon fiber was the only real choice.

Use Case 4: Industrial Handheld Devices

In medical and field inspection gear, I’ve seen custom CF cases used for:

- X-ray tablet enclosures

- Rugged handheld IR thermometers

- Data collectors

Design Focus:

- Ergonomics (contoured edges)

- Chemical resistance

- Easy grip textures (optional vinyl or rubber overlays)

Use Case 5: Presentation & Luxury Packaging

Yep, carbon fiber cases don’t always need to be practical. Sometimes they just need to look good—like in:

- High-end watch boxes

- Collector knife cases

- Limited-edition product kits

Design freedom here is massive. One client wanted laser-etched carbon fiber cigar cases. We did them. They turned out incredible.

Template Resource Table

Here are some open-source or reference-ready template types that work great as a starting point.

| Template Type | Platform | Suitable For | Link/Source |

|---|---|---|---|

| Smartphone Case (iPhone) | GrabCAD / Thingiverse | Entry-level design | grabcad.com |

| Laptop Enclosure (MacBook 13”) | GitHub | Advanced builds | Search “carbon laptop case” |

| Drone Frame (250mm) | Autodesk Gallery | Performance-first | gallery.autodesk.com |

| Controller Housing (Arduino) | Thingiverse | Industrial/DIY devices | thingiverse.com |

| 2-Part Clamshell Enclosure | Fusion 360 Templates | Medical & rugged gear | Fusion 360 asset store |

If you’re short on time, start from a template. Modify dimensions, add ports, and personalize. Saves 80% of the design work.

How to Evaluate If a Product Needs a Carbon Fiber Case

| Product Type | Do You Need CF? Why/Why Not? |

|---|---|

| Consumer gadget (like a phone) | ✅ Yes – Durable, light, stylish |

| Server or static electronics | ❌ No – Weight doesn’t matter |

| Drone or aerospace gear | ✅ Absolutely – Critical for weight |

| Rugged field device | ✅ Yes – Strength + chemical resistance |

| Desktop device (like router) | ⚠️ Maybe – Depends on thermal + aesthetics |

| Promotional item | ✅ Yes – Great for perceived value |

Designing a carbon fiber case isn’t limited to one product type. The versatility is wild. If you get the workflow right, you can build anything from tactical drone shells to ultra-luxury display boxes.

Chapter 7: Cost Estimation and Sourcing Tips

Let’s talk about money—because knowing how much a carbon fiber case really costs to make is essential, especially if you’re prototyping or scaling up for production.

In this chapter, I’ll walk through:

- Cost breakdowns (material, tooling, machining time)

- Price ranges based on my real-world experience

- Where I source materials and CNC services

If you’re on a tight budget, there are still ways to get professional-looking results. But you’ll need to plan your costs carefully.

Breaking Down the Total Cost of a Carbon Fiber Case

Here’s a basic breakdown of what goes into one average-sized carbon fiber case (say, a tablet-sized enclosure):

| Cost Element | Estimated Cost (USD) | Notes |

|---|---|---|

| Carbon fiber sheet | $25–$60 | Depends on thickness, finish, and supplier |

| End mills (per project) | $10–$25 | Expect 1–2 tools per job for small runs |

| Machine time (if in-house) | ~$0 (sweat equity) | Assume you own a machine; otherwise, use outsourcing cost |

| Outsourced CNC time | $60–$150 | Typical range for low-volume machining |

| Fixture materials (MDF/tape) | $5–$10 | Mostly consumables |

| Post-processing materials | $5–$15 | Sandpaper, sealant, logo decals |

✅ DIY (in-house CNC): Total = $45–$100 per case

💼 Outsourced: Total = $100–$250 per case

Factors That Influence Cost the Most

- Sheet Quality & Size

Higher weave quality or gloss coatings bump up the price. Larger sheets = bulk discounts. - Tool Wear & Bit Choice

Cheap bits wear fast. High-end bits last longer but cost more upfront. - Machining Time

More intricate designs or deep pocketing = longer cut time = higher hourly CNC shop costs. - Finishing Expectations

Want a showroom-grade case? You’ll spend more on post-processing.

Money-Saving Tips from My Builds

- Group small parts together on one sheet to save waste

- Use standard screw hole patterns to avoid custom jigs

- For early prototypes, try fiberglass-carbon hybrids—cheaper, but looks 90% similar

- Order tools in packs of 5–10—you’ll use them anyway

- Ask CNC shops for multi-part batch quotes (5–10 units)

Where to Buy Carbon Fiber Sheets (My Picks)

| Supplier | Region | Strengths | Website |

|---|---|---|---|

| DragonPlate | USA | Aerospace-grade, huge variety | dragonplate.com |

| Easy Composites | UK/EU | High detail sheets, international ship | easycomposites.co.uk |

| CNCarbon Fiber | China (Alibaba) | Low-cost, large MOQ | alibaba.com |

| Rock West Composites | USA | Engineering support + carbon tubes | rockwestcomposites.com |

| HobbyKing | Global | Budget drone-grade sheets | hobbyking.com |

I personally use DragonPlate for premium builds, and CNCarbon via Alibaba for budget batches or when weight isn’t mission-critical.

Where to Get CNC Machining Services

If you don’t own a CNC machine—or if you’re doing a bigger run—you’ll need someone else to cut your carbon fiber case.

Top Recommendations:

- SendCutSend (USA): Now offers CF; great for prototypes

- Xometry: Broad service matching, pricey but reliable

- PCBWay (China): Surprisingly good at CF cuts if you give tight specs

- Local CNC job shops: Best for fast turnaround and tight communication

- Online CNC forums: Try Reddit r/CNC or hobby forums for freelancers

When to Go DIY vs When to Outsource

| Project Type | Recommended Method |

|---|---|

| One-off prototype | DIY if you have access |

| Kickstarter or batch run | Outsource |

| Student or hobby build | DIY |

| High-value product housing | Outsource for precision |

| Concept sample or MVP | Either (depends on time and tools) |

There’s no one-size-fits-all answer to cost, but the more you plan, the more value you’ll squeeze out of each build. I’ve made custom carbon fiber cases for under $60—and I’ve made some that cost over $200. The key is knowing when to optimize and when to invest.

Chapter 8: Pro Tips and Common Pitfalls

No matter how well you plan, carbon fiber case projects can go sideways fast. Over the years, I’ve made just about every mistake you can imagine—and I’ve learned from each one.

This chapter is where I share the stuff most tutorials and product pages skip. It’s also where you can save serious time, money, and frustration.

Pro Tips for CNC Machining Carbon Fiber Cases

✅ 1. Always Run a Dry Pass First

Before cutting your actual part, do a dry run with the spindle off. This helps check toolpaths, depth clearances, and reveals if your G-code’s got surprises.

✅ 2. Use a Fresh Bit for the Final Pass

Even if your bit seems sharp, carbon fiber wears it down fast. A dull tool ruins edge quality. I always swap in a new or lightly-used endmill for the final contour pass.

✅ 3. Let Dust Settle Before Opening the Enclosure

After machining, let your dust collection run for 1–2 minutes before opening. This minimizes airborne fiber particles—your lungs will thank you.

✅ 4. Add Chamfers in CAD, Not by Hand

Adding edge chamfers in CAD ensures they’re consistent and machine-cut. Hand-sanding chamfers leads to uneven, “chewed” corners.

✅ 5. Log Your Feed & Speed Settings

Keep a spreadsheet of what worked for each thickness/material. You’ll thank yourself later. I’ve wasted hours guessing on setups I already figured out six months ago.

Mistakes That Cost Me (and How to Avoid Them)

| Mistake | What Happened | Fix |

|---|---|---|

| Forgot to zero Z after tool swap | Cut through fixture plate, ruined bit | Always re-zero after swapping tools |

| Used cheap double-sided tape | Sheet lifted during final pass | Use high-strength industrial tape (e.g., VHB) |

| Didn’t mask drill holes | Top carbon layer flaked out | Place painter’s tape over drill zones |

| Ignored static buildup | Dust stuck to machine, hard to clean | Use anti-static hose + grounding wire |

| Rushed sanding with no mask | Respiratory irritation for 3 days | Wear a proper P100 or N95 respirator |

Safety Pitfalls That Most People Overlook

Even experienced makers sometimes treat carbon fiber like wood or plastic. That’s a problem. Here’s what you can’t afford to ignore:

⚠️ Carbon Fiber Dust

It’s electrically conductive and can damage your electronics, lungs, and skin.

- Always vacuum, never brush

- Use a HEPA-grade system—shop vacs without filters blow it right back out

- Clean machines after every job

⚠️ Bit Breakage Mid-Cut

This often happens if:

- Your feed is too low and tool is rubbing

- You plunge too deep on a contour pass

- The collet is slightly loose

Always keep your ear out—screeching = trouble.

⚠️ Heat Buildup

No coolant = more heat. Slow feed = more heat. Result? Melted resin or warped sheet.

Solution? Find the sweet spot: fast enough feed to evacuate chips, but not so fast the bit chatters.

Bonus Tips from the Field

- For fine internal details, consider using a small finishing tool after roughing with a larger bit.

- For edge sealing, CA glue (cyanoacrylate) applied with a Q-tip works surprisingly well—just sand lightly after.

- Label every part before post-processing. Raw CF panels all look the same when unmarked.

- If you’re doing a hinged carbon fiber case, print your hinges from nylon and screw into inserts—you’ll get a perfect hybrid build.

Simple Troubleshooting Table

| Symptom | Probable Cause | Recommended Fix |

|---|---|---|

| Bit breaking at start | Plunge too aggressive | Use ramp or helical entry |

| Frayed edges | Dull tool, too slow feed | Replace bit, increase feedrate |

| Sheet vibrates or hums | Poor workholding | Add more tape or clamps |

| Smoky smell while cutting | Resin overheating | Increase feedrate or reduce spindle speed |

| Poor edge alignment (2-part case) | Shrinkage or warping | Cut both halves in the same job if possible |

I’ve learned most of these the hard way. Now you don’t have to.

Chapter 9: Appendices & Resources

As we wrap up this guide, it’s time to provide you with some final cheat sheets, comparison tables, and additional resources that will help you get started with your carbon fiber case project or refine your current process.

This chapter will help you quickly reference the most critical information from the entire manual, plus give you access to resources that can support you as you continue machining carbon fiber.

Appendix A: Carbon Fiber vs Aluminum vs Plastic – A Quick Comparison

Carbon fiber, aluminum, and plastic are often considered the main choices when designing cases. Here’s a quick comparison table to help you decide which material is best for your project:

| Property | Carbon Fiber | Aluminum | Plastic (ABS, PVC) |

|---|---|---|---|

| Strength-to-Weight | Excellent: 3x stronger than steel, lightweight | Good: Strong but heavier than CF | Low: Much weaker compared to CF & aluminum |

| Durability | Extremely high, resistant to impact and corrosion | High, prone to dents/scratches | Moderate, more prone to wear and cracks |

| Machinability | Difficult: Requires precision and specialized tools | Moderate: Easier but soft material | Easy: Can be cut quickly with standard tools |

| Cost | Expensive: Higher material & machining costs | Moderate: Good balance of cost and strength | Inexpensive: Widely available and cheap |

| Applications | Aerospace, high-end electronics, motorsports | Tech, automotive, military | Consumer products, housings for low-stress environments |

Key Takeaways:

- Carbon fiber is ideal for high-performance applications where strength-to-weight ratio is critical.

- Aluminum is more cost-effective for general use but lacks the weight-saving properties of carbon fiber.

- Plastic is suitable for lighter-duty applications or low-cost prototypes.

Appendix B: CNC Machine Setup Checklist

If you’re setting up your machine to cut carbon fiber cases, here’s a quick checklist:

| Component | Action |

|---|---|

| CNC Machine | Ensure spindle speed is between 10,000–30,000 RPM |

| Tooling | Use solid carbide endmills (1.5–3.0mm) with DLC coating |

| Dust Collection | Set up HEPA-grade vacuum system for maximum dust removal |

| Fixturing | Secure material with double-sided tape or clamps |

| Coolant | None needed—dry cutting only |

| Safety Gear | N95 respirator, safety glasses, gloves |

| Feedrate | Set feedrate to 300–500 mm/min for light cutting |

| Post-Processing Setup | Prepare sandpaper (600–1000 grit) and resin for edge sealing |

Appendix C: Final Cheat Sheet for Carbon Fiber CNC Machining

| Task | Quick Tip |

|---|---|

| Choosing Carbon Fiber Type | For strength: go with prepreg. For cost: woven twill. |

| Tool Selection | Use solid carbide DLC-coated bits for clean cuts. |

| Fixturing Carbon Fiber | Double-sided tape is your best friend for a quick, secure hold. |

| Speed and Feed Rate | Start slow—feed rate 300mm/min, spindle speed 18,000 RPM. |

| Post-Processing | Light sanding with 600–1000 grit, then apply resin or epoxy to seal edges. |

| Cleaning Up | Always vacuum thoroughly and wear a respirator. |

Conclusion

We’ve covered everything from selecting the right carbon fiber sheet to machining the perfect carbon fiber case. Now it’s up to you to put this knowledge into practice.

Whether you’re prototyping a carbon fiber case for a smartphone, designing drone frames, or building high-end luxury enclosures, the techniques I’ve shared are tried, tested, and refined through years of experience.

Don’t forget: carbon fiber is more than just a material—it’s a tool for creating something that balances strength, lightness, and performance. It’s an exciting field, and I hope this guide helps you get started on your own projects.

Good luck with your CNC machining, and remember to always learn from each part you cut. The journey to mastering carbon fiber is one of trial, error, and innovation. Keep pushing the limits!

FAQ

1. Can I CNC machine carbon fiber at home?

Yes, it is possible to CNC machine carbon fiber at home if you have the right equipment. You’ll need a CNC machine capable of high spindle speeds (10,000-30,000 RPM), dust collection system, and appropriate safety equipment (respirator, safety glasses, gloves). Make sure to use solid carbide tools, as carbon fiber is abrasive and requires strong tools.

2. What type of CNC machine do I need for carbon fiber cases?

For carbon fiber, a CNC router or milling machine with a spindle speed of 10,000–30,000 RPM is ideal. Smaller desktop machines, like the Shapeoko or Tormach 770M, can handle 2D cuts and lighter carbon fiber sheets, but larger machines are better suited for more complex, 3D parts and thicker material.

3. What kind of tools are best for cutting carbon fiber?

Solid carbide end mills with a diamond-like coating (DLC) are ideal for cutting carbon fiber. These tools are specifically designed to handle abrasive materials, and their coating reduces wear and tear during the cutting process. Choose tools with a small diameter (1.5mm to 3.0mm) for fine detail work and larger diameters for rough cuts.

4. How do I prevent edge fraying when machining carbon fiber?

Edge fraying is a common issue when CNC machining carbon fiber. To avoid this, use a sharp, solid carbide tool and adjust the feed rate to prevent the material from chipping. Additionally, always use a finishing pass to smooth out edges and a low plunge rate to minimize stress on the material.

5. Do I need coolant when cutting carbon fiber?

No, you don’t need coolant when cutting carbon fiber. Carbon fiber does not conduct heat like metals do, and using coolant can make the cleanup process harder. Instead, focus on optimizing the feed rate and tool path to ensure the material does not overheat and the dust is effectively removed by a HEPA-grade vacuum system.

6. How thick should a carbon fiber case be?

The thickness of a carbon fiber case depends on its application. For smaller consumer electronics like smartphones and tablets, a thickness of 1.0mm to 1.5mm is typically sufficient. For larger enclosures or parts that require more strength, such as laptop shells or drone frames, 2.0mm to 3.0mm is ideal.

7. Can I use a carbon fiber case for a drone?

Yes, carbon fiber is a popular material for drone frames because of its excellent strength-to-weight ratio. For drone components, you typically use 2.0mm to 3.0mm thick carbon fiber. Be mindful of the weight savings—every gram counts, so aim for lightweight, well-structured components with minimal excess material.

8. How do I finish the edges of a carbon fiber case?

After machining the carbon fiber case, use sandpaper (600–1000 grit) to smooth out the edges. A fine sanding block can help to avoid damaging the weave pattern. After sanding, you can seal the edges with a layer of epoxy or UV-cured resin to prevent delamination and improve the appearance.

9. How long does it take to CNC machine a carbon fiber case?

The time required to machine a carbon fiber case depends on the complexity and size of the part. Small, simple cases might take 1–2 hours, while more intricate or larger parts (like drone frames or laptop shells) can take 4–6 hours or longer. Remember, setup time (fixturing, tool change, etc.) also factors into the total machining time.

10. How do I secure carbon fiber sheets for CNC machining?

You can secure carbon fiber sheets to the machine bed using double-sided tape, a vacuum table, or clamps. Double-sided tape is the easiest and most cost-effective option for small jobs, while vacuum tables are excellent for high-precision, large-volume machining.

11. Is it safe to machine carbon fiber?

Machining carbon fiber is safe as long as you follow the proper precautions. Wear an N95 or P100 respirator to protect your lungs from fine carbon dust. Always use HEPA-filtered dust collection systems to prevent particles from spreading. Additionally, ensure your workspace is well-ventilated and clean to avoid long-term exposure.

12. How much does it cost to CNC a carbon fiber case?

The cost of machining a carbon fiber case varies based on factors like material type, size, complexity, and machining time. For an in-house setup, costs are typically $45–$100 per case. Outsourcing the machining can range from $100 to $250 per case, depending on service providers, quantities, and design complexity.

13. Can I make a custom carbon fiber case at home?

Yes, if you have access to the right tools (CNC router or mill, solid carbide endmills, and safety equipment), you can make your own custom carbon fiber case at home. Keep in mind that carbon fiber is tough to work with, and the dustcan be hazardous, so having the right ventilation, PPE, and proper technique is crucial.

14. What are the common mistakes when machining carbon fiber?

Some common mistakes include:

- Using dull tools: Carbon fiber is abrasive, so sharp tools are a must.

- Not using the right feed rate: Slow feed rates can cause the material to overheat and burn.

- Ignoring safety: Carbon fiber dust is toxic, so always use a respirator and dust collection system.

- Improper fixturing: If the sheet isn’t properly secured, it can shift during cutting, leading to inaccurate parts.

15. Can I use carbon fiber in 3D printing?

Yes, carbon fiber filaments are available for 3D printing, combining carbon fiber with PLA, PETG, or nylon. These filaments give a similar aesthetic and lightweight properties, but they don’t match the strength and durability of CNC-machined solid carbon fiber sheets. For critical structural components, traditional carbon fiber sheets and CNC machining remain the best option.

16. What is the difference between woven and forged carbon fiber?

- Woven Carbon Fiber is made by weaving individual strands of carbon fiber into a fabric-like material. It provides strength in two directions and is commonly used for cosmetic purposes because of its distinct weave pattern.

- Forged Carbon Fiber consists of chopped carbon fiber pieces pressed into a mold. It’s more isotropic (uniform in all directions) and is stronger under impact but lacks the visual appeal of woven fabrics.

Authoritative Knowledge References

To ensure the information provided in this guide is both reliable and up-to-date, I’ve drawn from several reputable sources within the field of materials science, engineering, and CNC machining. Here are some authoritative resources that expand on the topics discussed in this manual:

- Carbon Fiber – Wikipedia

Carbon fiber is a high-performance material known for its strength-to-weight ratio. It’s widely used in aerospace, automotive, and other high-tech industries. For a deeper understanding of its composition, applications, and types, check out the full article on Wikipedia.

Link: Carbon Fiber – Wikipedia - CNC Machining – Wikipedia

CNC machining is a manufacturing process used to produce precise and complex parts. This resource outlines the basics of CNC machines, their applications, and the materials typically processed, including carbon fiber.

Link: CNC Machining – Wikipedia

Other Articles You Might Enjoy

- Carbon Fiber 3D Printer: The Ultimate Guide to High-Strength, Lightweight Printing

Introduction: What Is Carbon Fiber 3D Printing? Hello there, and welcome to my ultimate guide on carbon fiber 3D printer technology. I’ve spent a good chunk of my career around…

- What Is White Carbon Fiber? Applications and CNC Processing Explained

Introduction White carbon fiber is a fascinating material that combines the strength and lightweight properties of traditional black carbon fiber with a striking aesthetic appeal. Unlike the typical black or gray…

- Carbon Fiber Sheets in CNC Machining: Applications, Techniques, and Cost Insights

Introduction When it comes to lightweight and high-strength materials, carbon fiber sheets are among the top choices for industries like aerospace, automotive, and electronics. Their unique properties, such as rigidity,…

- Carbon Fiber Phone Case Uncovered: From Material Science to Cutting-Edge Machining

Why Carbon Fiber for Phone Cases? When you hear about a carbon fiber phone case, what’s your first thought? For many, it’s the image of a sleek, lightweight, and durable…

- Decoding Carbon Fiber Strain in Advanced Machining Applications

Introduction: The Unique Properties and Applications of Carbon Fiber I’ve always been fascinated by how materials behave under stress. Carbon fiber, in particular, has this almost legendary status in aerospace,…

- Fiberglass Rod for CNC Applications: Material Guide, Machining Tips & Use Cases

🟩 Introduction: Why Fiberglass Rods Matter in CNC Projects Fiberglass rods might seem like basic materials at first glance—just solid, lightweight rods made from reinforced plastic, right? That’s what I…

- Cutting-Edge Techniques for Machining Composite Materials: Overcoming Key Manufacturing Challenges

Introduction Composite materials have revolutionized various industries by offering a unique combination of strength, lightweight properties, and durability. Unlike traditional metals, composite materials are engineered by combining two or more…