Sheet metal fabrication refers to a variety of manufacturing processes that are used to create sheet metal. We can use multiple processes, including bending, punching, and welding, to create intricate functional parts with multiple features.

It doesn’t need to cost a lot to order custom sheet metal parts. We at Want.Net is a trusted partner in sheet metal fabrication services that can help you minimise production costs. This article will show you how to make this manufacturing process more economical, from designing cost-effective parts to selecting the right sheet metal material.

Select The Correct Material

Now you have a concept and a plan for getting a product to the market. In most of case, developers face one of the biggest challenges in this step: choosing a sheet metal material. Indeed, choosing the right material can be a headache.

Below are some questions that have to be clarified when selecting the materials:

- The purpose of the parts. Is it a prototype or an end-use component?

- Does the part need to be durable for long-term usage?

- Does the part need to be chemically or heat resistant?

It is possible to replace an industrial-grade stainless with a cheaper aluminium grade without compromising the quality of the part. If you need help selecting the correct material for your custom parts, feel free to contact our support team. Our technical experts are always happy to answer your question.

Use Loose Tolerances

Bends, holes and slots are common features in custom sheet metal parts. While some features are essential to the function, others might not. It is important to know the difference between critical and non-critical features when designing and manufacturing sheet metal parts.

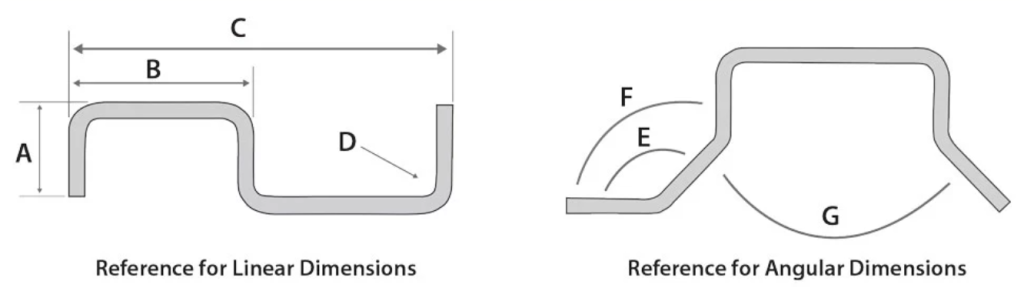

| Type | Unit | Thickness ≤ .080 | Thickness .080 – .130 | Thickness ≥ .131 | |

| A | Linear | Inch | ±0.010 | ±0.020 | ±0.030 |

| B | Linear | Inch | ±0.010 | ±0.020 | ±0.030 |

| C | Linear | Inch | ±0.020 | ±0.030 | ±0.060 |

| D | Linear | Inch | ±0.020 | ±0.020 | ±0.020 |

| E | Angular | Degrees | ±0.500 | ±0.500 | ±1.000 |

| F | Angular | Degrees | ±1.000 | ±1.000 | ±2.000 |

| G | Angular | Degrees | ±2.000 | ±2.000 | ±2.000 |

Each feature’s importance should be expressed in the tolerance it is allowed to operate.

If the part is going to be damaged by a lack of precision, part designers should specify tight tolerances. If this is not possible, the manufacturer may be able to perform the metal cutting service faster and with a lower tolerance.

A good rule of thumb is only to use tight tolerances when necessary.

Bend Easily and Uniformly

Most sheet metal parts have at least one bend. This feature is usually provided by a machine called a brake. It clamps the sheet metal in place before it bends along a defined line.

The cost of sheet metal bending will vary depending on how many and what type of bends are required. You need to ensure that your bends are simple and uniform in order to create custom sheet metal parts at a reasonable price.

First, make bends that are simple to perform and will hold their shape over time. This means that you should avoid small bends on thick sheets because they are hard to do.

Most brakes can bend metal accurately up to 120 degrees. Another good rule of thumb is not to reduce the bend radius by more than the thickness of your metal.

It is more expensive to do multiple bends at different angles. You’ll be able to reduce labor costs and maximize profit if you can maintain the same angle throughout.

Select a Standard Gauge

It is better to make custom sheet metal parts than to modify the sheet metal to fit your parts.

Also, don’t design parts that use non-standard gauges of sheet metal. This will create a significant cost burden for your project, which may be completely avoidable.

You should consider designing parts that use common metal thicknesses if you can. Because thinner metal is easier to cut and bend, it’s also easier to work with. It may not be necessary to have a very strong part, so it might be more cost-effective for you to use thinner sheet metal.

Other Articles You Might Enjoy

- Advanced Sheet Metal Fabrication Solutions for the Electronic Sector

Sheet metal fabrication stands as a crucial process within the electronics industry, instrumental in crafting a plethora of components that underpin electronic devices. This technique involves shaping and joining metal…

- Sheet Metal Fabrication for Automotive Industry

Introduction to Sheet Metal Fabrication in the Automotive Industry Sheet metal fabrication is a cornerstone process in the automotive industry, essential for constructing vehicle frames, bodies, and components. It involves…

- High-Density Polyethylene (HDPE) vs. PVC: Which is Better for CNC Fabricated Parts?

Introduction to CNC Fabrication and the Role of HDPE and PVC CNC fabrication is a technologically advanced process utilized in various industries for producing high-precision parts and components. The method…