CNC Machining and Composite Materials: Carbon Fiber and Kevlar

Computer Numerical Control (CNC) machining is a highly precise and automated process employed in manufacturing industries to create intricate parts and components. It leverages digital blueprints and programmed code commands while ensuring accuracy, speed, and repeatability of the process. When it comes to composite materials such as Carbon fiber and Kevlar, their incorporation into CNC machining has revolutionized various industry verticals.

- Carbon Fiber: Characterized by its high strength, light weight, and temperature resistance, carbon fiber offers excellent dimensional stability. These properties make it an invaluable asset in areas like aerospace and automotive industries where lightweight yet robust materials are needed.

- Kevlar: Boasting five times more strength than steel at equivalent weight, Kevlar provides exceptional durability, heat resistance, and flexibility. Its applications stretch across military armor, fire protective clothing, ropes, cables, etc.

The use of carbon fiber and Kevlar within CNC machining further bolsters efficiency, providing manufacturers with superior solutions for crafting unique, high-quality products.

Understanding Composite Materials: Carbon Fiber and Kevlar

Carbon fiber arises from a process that heats strands of carbon atoms in thin filaments of crystal structure. This engineered material is renowned for its lightweight frame but high strength and stiffness, making it superior to most metals. Its properties are largely due to its low thermal expansion conductibility. In the aerospace industry, carbon fiber’s lightness combined with durability are utilized extensively for creating parts.

- Origin: Heating strands of carbon atoms in a controlled environment

- Structure: Thin filaments of crystalline structures

- Properties: Lightweight, high-strength,

stiff, and resistant to thermal expansion - Example use: Creating durable yet lightweight components in the aerospace industry

Kevlar has roots as an aramid synthetic fiber discovered by Stephanie Kwolek at DuPont in 1965. Renowned for its heat resistance and toughness, Kevlar boasts a structure composed of long chains of molecules parallel to each other and linked by hydrogen bonds. As a result of this rigid composition, Kevlar fibers provide high tensile strength—particularly advantageous for manufacturing bulletproof vests in the security industry.

- Origin: A product of Dupoint, discovered by Stephanie Kwolek in 1965

- Structure: Long chains of molecules held together by hydrogen bonds

- Properties: Heat-resistant, strong, durable

- Example use: Manufacture of bullet-proof vests in security industries

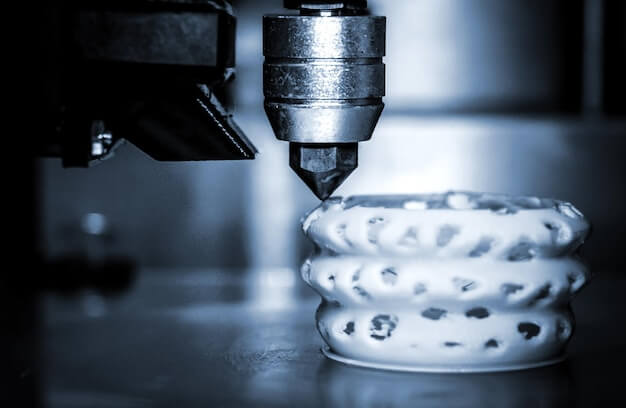

The Process of CNC Machining and its Application to Composite Materials

The workflow of the Computer Numerical Control (CNC) machining process begins with digital schematic plans which are typically created using computer-aided design (CAD) or computer-aided manufacturing (CAM) software programs. These plans guide the movements of the machinery, allowing it to seamlessly cut, drill or shape the material with high precision. This is achieved through the conversion of the designs into numerical inputs that instruct the machine’s mechanics.

Several stages are involved in this process:

- Designing the Part: The first step involves creating a 3D model of the part to be machined using CAD software.

- Converting the Model into a CNC Program: This stage includes translating the CAD drawing into G-code, which serves as a language known by the machining tool.

- Preparing the Machine: This phase encapsulates setting up the tooling necessary for actual cutting operations, such as installing specific drills or load materials like metals or composites onto the worktable of the CNC machine.

- Machining the Part: At this final stage, the CNC machining starts off, adhering strictly to specifications highlighted in the program.

In relation to composite materials such as Carbon Fiber and Kevlar, the CNC method offers precise cuts with minimal errors. Its programmable nature makes it an ideal option for working with these complex materials, ensuring consistency across multiple productions while limiting waste and enhancing efficiency. Given their unique properties – marked by high strength-to-weight ratios and heat resistances, proper care has to be taken at the programming level while processing these composites which enhance overall productivity.

CNC Machining for Carbon Fiber: Understanding the Process and Challenges

When CNC machining carbon fiber, it’s important to understand the process and challenges involved:

- Tooling Selection: Choose specialized cutting tools designed for carbon fiber machining to minimize delamination and fiber pullout.

- Workholding: Implement secure and stable workholding methods to prevent vibration and ensure accurate machining of carbon fiber components.

- Dust Control: Employ effective dust extraction systems to manage the fine carbon fiber particles generated during machining and maintain a clean working environment.

CNC Machining for Kevlar: Process, Challenges and Real-life Example

The process of CNC machining Kevlar involves the strategic cutting and shaping of this strong yet lightweight material using a computer numerical controlled (CNC) machine. This high-performance technology enables precision tooling that is essential in forming intricate shapes out of Kevlar.

- Challenges: However, working with Kevlar is not without its challenges. Notably, due to its highly abrasive nature, it can wear down machining tools quicker than other materials like aluminum or steel. Furthermore, controlling the fraying during the cutting process is challenging as well.

- Real-life example: Despite these issues, manufacturers often choose Kevlar over carbon fibers in industries like aerospace and automotive because of its impressive strength-to-weight ratio. For instance, it’s extensively used in the production of Formula 1 cars where every gram counts, but safety cannot be compromised which is evident from their precise, CNC machined brake discs.

Comparing Carbon Fiber and Kevlar in CNC Machining

In CNC machining, it’s important to consider the unique characteristics of materials like carbon fiber and Kevlar. Both have distinctive qualities that require careful handling during machining processes. However, they share similarities in their high strength-to-weight ratios and resistance to wear.

- Carbon Fiber: In general, carbon fiber sports a stiff and strong nature. However, its rigidity also renders it more susceptible to cracking or chipping throughout the CNC machining process, particularly under high pressure conditions. This trait may necessitate slower feed rates and specific tool geometries for effective machining.

- Kevlar: On the other hand, Kevlar manifests flexibility which can result in delamination while machining. Nonetheless, this can be managed effectively by adopting suitable cutting parameters and using sharp tools to ensure clean, precise cuts. Its resilience makes Kevlar outstandingly impact-resistant, performing better than carbon fiber under conditions with potential physical impacts.

Pick the optimal material for your CNC project requires examining these set factors amidst other considerations such as cost, aesthetic appeal, heat resistance, and overall application purpose.

Conclusion

In conclusion, the CNC machining of both Carbon Fiber and Kevlar composites has important strengths and constraints. Carbon Fiber provides remarkable stiffness, strength-to-weight ratio, as well as thermal expansion properties; however, it is comparatively more expensive and poses health risks during fabrication. On the other hand, Kevlar offers greater energy absorption, flexibility, and resilience to tear but lacks rigidity compared to Carbon Fiber. Understanding this comparison between Carbon Fiber and Kevlar in terms of CNC machining is crucial because it allows for informed material selection based on the specific application needs, considering factors such as cost-effectiveness, safety during the manufacturing process, and performance requirements.

Other Articles You Might Enjoy

- Is Copper the Right Choice for Electrical Component CNC Machining? A Detailed Analysis

CNC Machining of Electrical Components Utilizing Copper In the field of electrical engineering, Computer Numerical Control (CNC) machining plays an integral role, particularly in the development and manufacturing of electrical…

- Understanding Bead Blasting in CNC Machining(china machining Avery)

Bead blasting, a compelling term in the world of Computer Numerically Controlled (CNC) machining, is an influential process that plays a transformative role in optimizing and enhancing parts' aesthetic and…

- Understanding Bead Blasting in CNC Machining(cnc g code Jacqueline)

CNC (Computer Numerical Control) machining is a dominant method employed for multiple manufacturing systems across the globe. From healthcare to aerospace, this technology has revolutionized how we manufacture products. One…