Introduction: CNC Machining and Smart Wearables

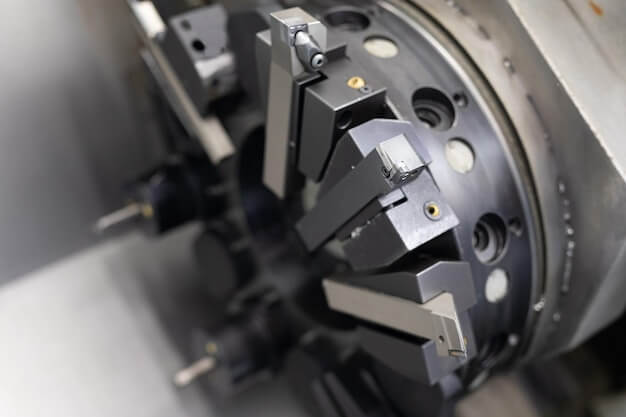

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to operate and manipulate machine tools, converting raw materials into finished products. On the other hand, smart wearables refer to electronic devices with microcontrollers worn on the body as accessories or implants providing advanced capabilities and features using IoT technology. The symbiotic link between these two spheres comes in their production processes. As precision is paramount in creating small, intricate parts for wearable devices, CNC machining becomes a key player due to its high accuracy levels and replication efficiency. Its extraordinary versatility allows developers to bring the complex designs of smart wristbands, fitness trackers, if not more, to life by milling various materials to accurate specifications.

- CNC Machining: known for high precision and repetition efficiency, vital for making tiny, intricate components for smart wearables.

- Smart Wearables: involves intricate designs difficult to manufacture manually, thus warranting the use of technologically sophisticated methods like CNC machining.

The Evolution of CNC Machining in Manufacturing

CNC machining has significantly evolved since its inception during the mid-20th century. Over time, it underwent a rapid development as digital software replaced punched tape technology to orchestrate machine movements on all three axes. Later on, multi-axis machining was introduced, affording manufacturers almost limitless possibility for part design and production.

One significant breakthrough that revolutionized the application of CNC machining is high-speed machining (HSM). Introduced during the late 1990s, HSM opened up new opportunities in the industry through its ability to remove material from workpieces at more robust and faster rates, leading to reduced cycle times and increased production efficiency. This innovative technique completely changed how industries such as automotive, aerospace, medical devices, and manufacturing of wearable tech approach their operations.

- Computer Numerical Control (CNC) – Automated control of machining tools by means of a programmable computer system.

- Punched Tape Technology – Earliest form of data storage used to feed instructions into machines

- Multiaxis Machining – Milling method where CNC machines operate on an X, Y and Z axis; enables complex parts production in one setup

- High-Speed Machining (HSM) – Technique utilized when the speed rate of the removed component exceeds the cutting speed; optimizes both tool performance and cost-effectiveness

The Emergence of Smart Wearables

Over the past few years, smart wearables have reached a level of ubiquity in everyday life. From fitness trackers and smartwatches to health monitors and augmented reality glasses, these devices are revolutionizing not just how we interact with technology, but also how we approach personal wellness and productivity. The rise of smart wearables can be attributed largely to advancements in CNC machining techniques, which have made it possible to produce smaller, more intricate components at a cost-effective scale.

An excellent example reflecting this growth is our dependence on fitness trackers or wearable heart-rate monitors in managing our health. These devices continuously track and compile data during exercise sessions, creating personalized reports regarding calories burned, steps taken, sleep pattern analysis, etc. Instead of visiting clinics for routine check-ups, users get real-time insights about their bodies directly on their wrists. This has given everyone direct control over managing their well-being, demonstrating the profound impact that the proliferation of smart wearables has had on our everyday lives.

Integration of CNC machining into the smart wearable industry:

- Step 1: CNC machining is being integrated into the smart wearable industry to produce intricate and precise components for wearable devices.

- Step 2: The process allows for the creation of custom parts with high accuracy and quality, meeting the demands of the smart wearable market.

- Step 3: To explore CNC machining services for smart wearables, consider utilizing online CNC service for efficient and reliable manufacturing.

Potential Challenges in Integrating CNC Machining to Manufacture Smart Wearables

Integrating Computerized Numerical Control (CNC) machining into the manufacturing process of smart wearables presents several challenges. Users and manufacturers might encounter difficulties related to precision, device compatibility, and software constraints. These issues could affect production efficiency, increase costs and potentially compromise on product quality.

- Precision: Creating complex designs with high levels of detailing in wearable items can be challenging due to the small sizes typically involved.

- Device Compatibility: As most smart wearables require integration with mobile devices or other equipment, manufacturers may face difficulty ensuring seamless functional compatibility between these different tech pieces.

- Software Constraints: Operating CNC machines might also imply coping up with limitations posed by proprietary software systems, such as customization constraints.

To overcome these potential hurdles, solutions like investing in advanced micro-machining tools for better precision, conducting comprehensive compatibility tests, and utilizing open-source, customizable software platforms can be implemented. Furthermore, seeking expert consultation during the design and implementation stages can provide valuable insights into optimizing the whole manufacturing process effectively.

Future Improvements & Innovations in CNC Machining for Smart Wearables

The evolution of Computer Numerical Control (CNC) machining, according to industry experts, will have a considerable impact on the future production of smart wearables. They predict an era defined by advanced precision, speed, efficiency and automation that will further fuel innovations in the wearables sector.

- CNC machines may employ artificial intelligence (AI) techniques to perform autonomous decision-making processes enhancing accuracy and production rates.

- Anticipated improvements in high-speed machining technology will accelerate production time scales, translating into reduced lead times and overall costs.

- Experts foresee advancements in virtual reality (VR) or augmented reality (AR) technologies being integrated into CNC systems; this might provide real-time simulations during the design phase thereby reducing errors and wastage.

Such continuous improvements can be instrumental in expediting the manufacturing cycle of smart wearables, while ensuring superior quality and performance. As these technological possibilities turn into realities, they may herald unprecedented ways to streamline and innovate within the burgeoning realm of wearable tech.

Related Posts

- Custom CNC Machining for High-Tech Security Systems

Introduction to CNC Machining for High-Tech Security Systems Custom Computer Numerical Control (CNC) machining plays an integral role in the production of high tech security systems. It is a manufacturing…

- Plastic vs. Metal CNC Machining: A Detailed Comparison?

CNC Machining: An Essential Process Across Industries Computer Numerical Control (CNC) machining is a digital manufacturing technology that makes use of pre-programmed computer software to dictate the movement of various…

- Tool Steel Grades for CNC Machining: D2 vs. A2 - A Comparative Study?

Introduction to CNC Machining and Tool Steel CNC machining, or computer numerical control machining, is a manufacturing method that employs pre-programmed software to direct the activity of factory tools and…