CNC Machining and its Relation to Custom Architectural Hardware

CNC, an acronym for Computer Numerical Control, is a technology that utilizes computer commands to control machinery. By inputting digital instructions, CNC machines can perform precise operations on varied materials such as metal, plastic or wood, resulting in highly accurate pieces of work. This innovation has become paramount in various industries, including the production of custom architectural hardware.

The relationship between CNC machining and custom architectural hardware lies in their synergy when it comes to meeting unique, detailed design specifications. Architects and designers often have specific requirements for elements like door handles, window fittings, and furniture fixtures. Relying on traditional manufacturing techniques may lead to inaccuracies due to human error, but with CNC machining, these intricate designs can be executed flawlessly down to the finest detail. By removing the possibility of manual errors and increasing efficiency, CNC machining ensures precision in crafting tailor-made architectural hardware, aligning perfectly with architects’ vision and clients’ expectations. The main components involved in this process include:

- The user interface software where designs are inputted.

- The controller unit that interprets and executes these designs.

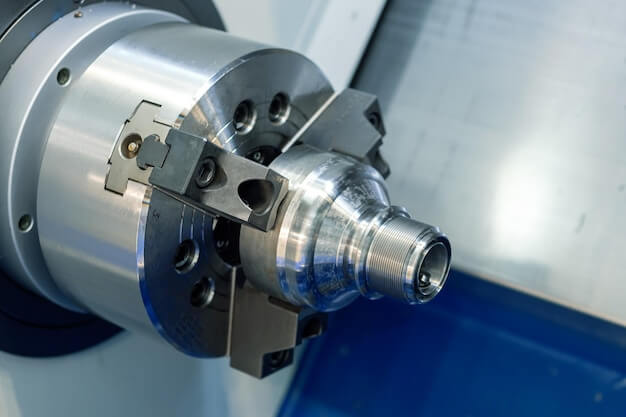

- The machine tool which fabricates the desired product based on these instructions.

Influence of Innovation in CNC Machining on Architectural Hardware

The technological advancement, particularly the innovation in CNC machining processes holds significant importance in the custom architectural hardware industry. Ever-evolving CNC machining technologies have substantially improved precision, efficiency and flexibility of manufacturing processes. These advancements enable manufacturers to create intricate designs which were previously impossible or costly.

As a specific instance, innovative CNC machining has been used extensively in the fabrication of customized door handles for high-end residential and commercial buildings. This process includes:

- Designing unique 3D models using advanced computer software

- Conversion of these designs into machine language

- Automatic cutting, drilling, and shaping of metals with impeccable accuracy through CNC machines

- Final finishing to achieve sophisticated aesthetics and long-lasting durability

.

This application underscores that innovation in CNC machining is not just an incremental improvement but a revolutionary asset in producing bespoke solutions in the realm of architectural hardware.

Advantages of Innovative CNC Machining for Custom Architectural Hardware:

- Step 1: CNC machining offers precise control of the cutting tool, high speeds for faster production, and consistent quality, making it suitable for creating custom architectural hardware with intricate designs.

- Step 2: The process allows for the production of complex shapes and geometries, providing flexibility in creating a wide array of architectural hardware parts.

- Step 3: CNC machining also offers increased accuracy, repeatability, and efficiency compared to traditional manual machining methods, ensuring the production of high-quality custom architectural hardware.

Case Study: An Innovative CNC Architectural Hardware Production Process

In a real-world application of innovative CNC machining, an international architectural hardware manufacturer recently revolutionised their production process with custom designed parts. Before the implementation, components were manually assembled which was laborious and time-consuming resulting in inconsistent product quality.

The new CNC technology dramatically improved both productivity and the output quality by automating key stages of the manufacturing process. The integrated system used three elements:

- Precision Machining: CNC controlled machines produced high precision parts consistently reducing errors.

- Metal Forming: Automated metal forming capabilities enabled greater speed and accuracy, while also reducing scrap rate.

- 3D surface inspection: This feature allowed for highly accurate, automated inspections ensuring superior quality control.

By implementing this technologically advanced system, throughput increased exponentially and overall product quality improved due to the consistent accuracy of machine-crafted parts replacing variable human craftsmanship. Additionally, it resulted in significant cost savings from reduced waste material and lower rework/repair rates.

Steps in Executing CNC Machining for Custom Architectural Hardware

The process of executing CNC machining for creating unique architectural hardware involves several key steps. First, the specific part design is inputted into the controlling software, usually defined by CAD/CAM programs. This design data guides the precision movements of the CNC machine throughout production. Second, the appropriate material – whether brass, steel, or a more exotic metallic compound – is chosen and loaded onto the machine bed.

Firm and accurate placement of this stock material is crucial to ensure exact alignment with the programmed tool paths. Thirdly, based on the complexity and type of the project, the required cutting tools are selected and installed into the machine. This may include drill bits, end mills, or lathe tools amongst others. Fourth, machine parameters such as speed, feed rate, coolant flow and tool path are meticulously set according to the stipulated specifications.

Finally, after all these pre-processing activities, the actual machining begins where the programmed tools will precisely carve, shape, and finish the work piece to create the desired custom-made architectural fitting. It’s important to monitor the entire operation closely to ensure that the finished piece meets the quality and accuracy standards expected.

Hurdles that Might Occur During CNC Machining

When utilizing innovative CNC machining for custom architectural hardware, users may encounter several challenges. One common problem is tool deflection or breakage due to incorrect feed rates and speeds which could also lead to poor surface finish on the final product. To alleviate these issues, operators should regularly review operating manuals for guidelines on appropriate speed settings, ensure they are using the suitable tools for a particular material, and conduct regular maintenance checks to keep the machine in peak condition.

In addition, complications could arise from improper programming of the CNC machine leading to unintended movement or operation, potentially damaging both the machine and workpiece. It’s crucial therefore for operators to be well-versed in G-code programming and verify dimensions, positions, and paths before initiating the machining process. Users might also experience difficulty with complex designs requiring high precision levels; however, leveraging robust CAM software could simplify this task by automatically converting CAD drawings into executable commands for the CNC machine.

Lastly, choosing unsuitable material for a specific design can cause challenges such as part deformation or wear and tear on cutting tools. Here, understanding material properties and matching them to necessary machining processes helps negate such problems.

Other Articles You Might Enjoy

- Custom Aluminum Machining: CNC Solutions for Specialized Components

Custom Aluminum Machining: CNC Solutions for Specialized Components Custom aluminum machining is a process that utilizes computer numerical control (CNC) to create specialized, unique hardware from aluminum. This tends to…

- The Art of Bead Blasting in CNC Machining(types of rivets David)

Bead blasting is a prevalent process that comes with the precision and defining methods of Computer Numerical Control (CNC) machining. Used globally in various industries, from automotive to aerospace, bead…

- Innovative CNC Machining for Custom Medical Instruments

Innovative CNC Machining for Custom Medical Instruments Computer Numeric Control (CNC) machining is an innovative automated process that utilizes computer software to control machine tools. The use of CNC machines…