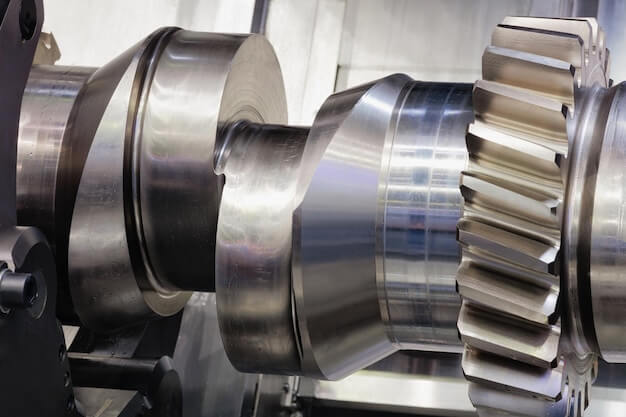

Bead blasting is a surface finishing technique widely used in Computer Numerical Control (CNC) machining. The main purpose of this technique is to enhance not only the visual aesthetics but also the mechanical properties of workpieces created through different manufacturing processes, whether it’s millwork or lathe work.

What exactly is bead blasting?

At its core, bead blasting involves forcibly propelling a stream of abrasive beads at high speed towards a surface by means of pressured air or centrifugal force. It primarily serves to clean, smooth, strengthen, or polish surfaces, adding functionality and beauty simultaneously.

In CNC machining, bead blasting plays an integral part in shaping the final appearance of components, facilitating proper function, durability, and longevity. This technique paves the way for parts that are excellent in their performance and visually pleasing when completed – distinct features prioritized by industries ranging from aerospace, automotive, medical, to name just a few.

How does the process of bead blasting work?

The entire procedure begins with preparing the workpiece. Depending on the intended outcome, various types of abrasive media such as glass beads, ceramic beads, plastic particles, aluminium oxide grit, or even crushed walnut shell can be used for the blasting process. Next, the chosen medium is loaded into a bead blasting machine equipped with a powerful compressor designed to propel these materials towards the workpiece effectively and efficiently.

The strength and speed of the process can be adjusted depending on what kind of finish is desired. For instance, a stronger pressure will result in a more matte effect, while slow-speed bead blasting can achieve a shinier one. Thus, bead blasting caters perfectly to custom requests which pertain to aesthetic preference and industry-specific needs.

Why choose bead blasting over other finishing methods?

Bead blasting boasts several benefits that make it an often preferred choice among customers and manufacturers alike:

1. Versatility: Bead blasting works extremely well across a vast range of materials – metal, wood, plastic or glass.

2. Precision: In CNC machining where the emphasis is on accuracy and precision, bead blasting’s ability to subtly alter small sections without impacting the entire piece significantly is valuable.

3. Environmentally Friendly: The used beads can often be recycled, contributing to less environmental waste produced during the machining process.

4. Enhances Performance: Aside from aesthetic improvements, bead-blasting aids in improving mechanical features such as resistance against wear and tear, corrosion, and stress-cracks that extend component’s life span.

The mastery of bead blasting in CNC machining translates not just into impeccable finished products but long-lasting customer satisfaction. Therefore, understanding, adopting and investing in this technique bears inherent value for every stakeholder within the realm of machining domain.

Remember though, successful execution of bead blasting relies heavily on skilled operators who possess deep knowledge and adept control over the whole process – right from choosing appropriate blasting media and adjusting machine settings aptly, till inspecting the completed work pieces vigilantly.

In conclusion, bead blasting forms an essential part of the broader picture of CNC machining, encapsulating strength, beauty, practicality, environmental friendliness, and versatility. As industries grow further technologically advanced, so will techniques like bead blasting, continually evolving while holding firm its fundamental benefits.

Other Articles You Might Enjoy

- Understanding Bead Blasting in CNC Machining(snap fits Rae)

Bead blasting is a critical process in the manufacturing industry, particularly within the realm of Computer Numerical Control (CNC) machining. It’s an integral aspect that greatly contributes to enhancing the…

- Is Copper the Right Choice for Electrical Component CNC Machining? A Detailed Analysis

CNC Machining of Electrical Components Utilizing Copper In the field of electrical engineering, Computer Numerical Control (CNC) machining plays an integral role, particularly in the development and manufacturing of electrical…

- Understanding Bead Blasting in CNC Machining(china machining Avery)

Bead blasting, a compelling term in the world of Computer Numerically Controlled (CNC) machining, is an influential process that plays a transformative role in optimizing and enhancing parts' aesthetic and…