The Advantages of Titanium Alloys in Aerospace Manufacturing

Aerospace manufacturing is an industry involved with the design and production of both aircraft and spacecraft. It encompasses two main sectors, aeronautics and astronautics, each having their own unique challenges that demand precise engineering solutions. One such solution often carried out in this dynamic field involves the use of titanium alloys. These minerals are positioned at the core of aerospace design due to their remarkable qualities which include high strength-to-weight ratio, excellent corrosion resistance, and superior performance at extreme temperatures. The following points detail the benefits:

- Titanium’s high strength-to-weight ratio makes it ideal for components that need to withstand enormous stress but still remain lightweight.

- The corrosion resistance characteristic prolongs the lifespan of these components, offering enduring reliability and lower maintenance costs.

- Finally, the ability of titanium alloys to maintain their properties under extreme heat conditions provides an essential advantage especially in processes like jet propulsion where high temperatures prevail.

This strategic application of titanium alloys in aerospace manufacturing ensures not only optimum functionality of aircrafts but also inspiring advancements in spacecraft design.

Exploration of Titanium and Its Properties

Titanium, from a metallurgical perspective, is a silver-colored transition metal characterized by high strength, low density, and resistance to corrosion even in harsh environments such as sea water and chlorine. This hardy material derives these beneficial properties from a naturally occurring oxide film on its surface that works efficiently to protect it from many forms of damage.

- Definition and Understanding: Titanium possesses an atomic number 22 on the periodic table and is distinguished by its excellent strength-to-weight ratio. Although almost twice as heavy as aluminum, titanium is over twice as strong, making this metal superior for situations where both strength and weight are significant factors.

- Natural Characteristics: A unique trait of titanium lies in its remarkable resistance to corrosion attributed to the continuous formation of a stable and adherent oxide layer. Should the oxide layer be mechanically removed or damaged, it practically reincorporates itself upon exposure to air and water which helps to ensure reliability and increases component lifetimes. Furthermore, its low thermal expansion coefficient results in enhanced fatigue strength, thus augmenting its suitability for aerospace manufacturing.

Understanding the Concept of Alloys

The term ‘alloy’ refers to a mixture of two or more metals combined together to enhance their properties. This simple yet significant metallurgical concept plays an essential role in different sectors, particularly in aerospace manufacturing. In this context, alloying can be crucial for various reasons. For example, alloys can provide increased strength, corrosion resistance, and heat tolerance – all key attributes required for materials used in the construction and maintenance of aircrafts.

- Increased strength: Often, pure metals are not strong enough to withstand the harsh conditions faced by aircraft during flights. Alloys help to increase tensile strength and hardness, making them suitable for use in high-stress environments.

- Corrosion Resistance: Aircraft are regularly exposed to humid and salty conditions which may lead to corrosion. Alloying metals make them highly resistant to such damaging effects, ensuring longevity and reliability.

- Heat Tolerance: Due to high flying speed, parts like engines face intense heat. The ability of alloys to resist extreme temperatures greatly contribute to maintaining these parts effectively.

In sum, understanding the process and benefits of alloying is paramount in order to appreciate its critical presence in aerospace manufacturing.

Generation of Titanium Alloys

Titanium alloys are produced through a multi-step process that involves blending pure titanium with other elements to enhance its properties. Let’s explore the generation of titanium alloys in aerospace manufacturing.

1. Alloying Process

The alloying process begins with the selection of suitable alloying elements based on the desired properties of the final alloy. Common alloying elements used in titanium alloys include aluminum, vanadium, and tin. These elements are added to the pure titanium in precise proportions.

2. Melting and Casting

Once the alloying elements are added, the mixture is melted in a controlled environment, such as a vacuum or inert gas atmosphere, to prevent contamination. The molten alloy is then cast into a desired shape, such as ingots or billets, using techniques like vacuum arc melting or electron beam melting.

3. Heat Treatment

After casting, the titanium alloy undergoes a heat treatment process to optimize its microstructure and mechanical properties. This typically involves heating the alloy to a specific temperature and holding it for a certain duration, followed by controlled cooling. Heat treatment helps in achieving the desired balance of strength, ductility, and other mechanical properties.

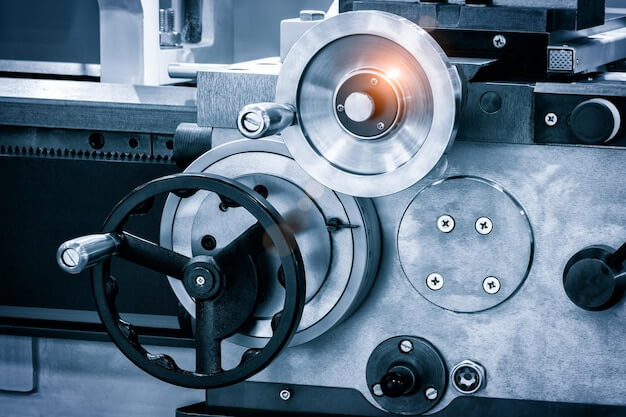

4. Machining and Finishing

Once the titanium alloy is in the desired form, it can be further processed through CNC machining, precision machining, sheet metal fabrication, or other manufacturing techniques. These processes involve shaping, cutting, and finishing the alloy to meet the specific requirements of aerospace components.

5. Quality Control

Throughout the generation process, quality control measures are implemented to ensure the integrity and consistency of the titanium alloy. This includes non-destructive testing, dimensional inspections, and material analysis to verify the alloy’s composition and properties.

In conclusion, the generation of titanium alloys in aerospace manufacturing involves the alloying of pure titanium with other elements, followed by melting, casting, heat treatment, and machining processes. These steps are crucial in producing titanium alloys with enhanced properties suitable for various aerospace applications. By utilizing advanced manufacturing services like online CNC service, Precision Machining Service, Sheet Metal Fabrication, or 3D Printing Services, aerospace manufacturers can efficiently produce high-quality titanium alloy components for aircraft.

The Unique Advantages of Titanium Alloys

One of the standout properties which elevates titanium alloys as an ideal material in aerospace manufacturing is its high strength-to-weight ratio. This characteristic ensures that structures made from these alloys are strong yet remarkably lightweight, a crucial requirement in the aviation industry to increase efficiency while reducing fuel consumption.

- High Strength-to-Weight Ratio:Titanium alloys provide strength comparable to steel but at approximately half the weight, making them indispensable in constructing aircraft components that demand durability without contributing excessive weight.

- Corrosion Resistance: Another pivotal attribute of titanium alloy tracing back their prevalence in aerospace applications is their notably pronounced resistance to corrosion. Even when exposed to environmental elements or harsh weather conditions, titanium alloys maintain their integrity and resist degradation, thereby significantly extending the lifespan of parts crafted with it.

This high resilience together with unmatched strength makes titanium alloys vital in creating robust, durable, corrosion-resistant airframes, jet engines, and other critical aerospace components. Hence, unveiling why Aerospace manufacturing heavily relies on this stellar metal amalgams for enhancing performance and longevity.

Utilization of Titanium Alloys in Aerospace Manufacturing

The utilization of titanium alloys in aerospace manufacturing has several significant advantages. These strong, lightweight and heat-resistant materials actively play essential roles in multiple facets throughout an aircraft’s structure. For instance, titanium alloys are frequently used for critical components such as engine parts; this includes turbine blades and compressor discs that have to withstand high temperatures and pressures.

- Engine Parts: Titanium alloys offer exceptional strength-to-weight ratios and corrosion resistance, making them ideal for producing the meticulously designed components of jet engines that regularly face extreme thermal conditions.

- Airframes: The airframe, a fundamental part of any aerospace vehicle architecture, often incorporates substantial amounts of titanium alloys. Using these alloys enhances the frame’s toughness and rigidity while reducing weight, resulting in enhanced performance and fuel efficiency.

- Landing Gear: The landing gear is another vital component wherein titanium plays a pivotal role due to its high fatigue strength and resilience against environmental damage, negating potentially disastrous effects from repeated take-off and landings.

In essence, with their sterling physical properties and impressive versatility, titanium alloys remain indispensable to modern aviation design and manufacture.

The Impact on Aircraft Performance

Titanium alloys bring about notable enhancements in aircraft performance, most notably improved endurance and fuel efficiency. Endurance is substantially boosted due to the superior strength-to-weight ratio of titanium alloys. This high-end material withstands extreme conditions, thereby extending an aircraft’s lifespan and reducing its upkeep/maintenance needs.

- Titanium Alloy’s inherent resilience under severe stress and heat translates into elongated service life for aircraft built with it.

Moreover, the naturally lightweight nature of these alloys greatly contributes to better fuel efficiency. One of the primary goals in modern aerospace manufacturing is weight reduction since lower weight equates to lower fuel consumption. The use of Titanium alloys aids in achieving this goal without sacrificing safety or durability.

- Airplanes created with lighter materials like titanium alloys can fly longer distances by using less fuel compared to their conventional counterparts.

Potential Drawbacks or Challenges with Using Titanium Alloys

Despite the numerous advantages titanium alloys bring to aerospace manufacturing, it is essential to consider their potential drawbacks and challenges. One significant setback often encountered in using these alloys is cost-related as they are expensive to refine. This high expense comes from multiple processes involved: mining of the raw material, refining to pure titanium, and alloying with other metals for enhanced properties. Additionally, machining of titanium alloys can be challenging due to its strength, requiring advanced equipment and causing wear on cutting tools, which further add to the overall costs.

- Mining of raw materials

- Refining to pure titanium

- Alloying with other metals

- Advanced equipment needed for machining

Related Posts

- The Advantages of Titanium Alloys in Aerospace Manufacturing

Aerospace Manufacturing and Materials In aerospace manufacturing, the key focus is on the fabrication of mechanical components designed for functions such as powered flight or navigation beyond Earth's atmosphere. This…

- CNC Machining for Aerospace: Titanium vs. Aluminum Alloys Comparison

CNC Machining in Aerospace Industry: Material Choice Significance CNC machining, an abbreviation for Computer Numerical Control machining, is a process utilized extensively in the aerospace sector. The technology relies on…

- CNC Machining for Energy Sector: Inconel vs. Titanium Alloys Performance Comparison

CNC Machining in Energy Sector: Inconel vs. Titanium Alloys The advent of CNC (Computer Numerically Controlled) machining has revolutionized the manufacturing industry, particularly within the energy sector. Known for its…