Aerospace Manufacturing and Materials

In aerospace manufacturing, the key focus is on the fabrication of mechanical components designed for functions such as powered flight or navigation beyond Earth’s atmosphere. This high-tech sector plays a pivotal role in modern transportation and defense systems. In this context, materials used bear paramount significance influencing multiple aspects like weight, strength, resistance against various atmospheric conditions, cost-effectiveness, sustainability, and durability. Metals, especially lightweight metals and their alloys, polymers, ceramics, composites, etc., are typically incorporated across different applications within aerospace infrastructure.

The Role of Titanium Alloys

Titanium alloys hold a significant place due to several advantages they offer. For instance:

- High Strength-to-Weight Ratio: This key characteristic facilitates air-craft efficiency by reducing unnecessary structural weight whilst maintaining structural robustness.

- Corrosion Resistance: Endurance against corrosion enhances the service longevity and reduces maintenance, thereby supporting sustainable engineering solutions.

- Temperature Resilience: Heat resilience contributes towards ensuring safety under extreme operating conditions frequently encountered in aerospace environments.

What are Titanium Alloys?

Titanium alloys, in their simplest definition, are a blend of titanium and other chemical elements that boast high strength-to-weight ratios, excellent corrosion resistance, and impressive heat resistance. These unique characteristics allow them to maintain their mechanical properties in extreme environments, making them perfect for aerospace manufacturing applications. For example, the Grade 5 titanium alloy – also known as Ti6Al4V – is heavily utilized due to its exceptional tensile strength and toughness, alongside its good welding and fabrication properties.

- Ti6Al4V (Grade 5): Known for excellent strength, toughness, and good weldability, making it ideal for airframe and jet engine parts.

- Ti5AI-2.5Sn (Grade 6): Appreciated for improved stability at higher temperatures and better weldability, often used in aircraft hydraulic systems.

- Ti3AI2.5 (Grade 12): Offers superior hot forming capabilities and boasts an optimal balance between strength and ductility.

In essence, these varying types of titanium alloys fit different specifications and needs within the industry, allowing manufacturers to choose the best material for their specific application.

Advantages of Titanium Alloys in Aerospace Manufacturing

The utilization of titanium alloys in aerospace manufacturing brings forth a myriad of benefits, primarily due to their superior mechanical properties and resilience. This section delves into the advantages of incorporating titanium alloys in the production of aerospace components, highlighting their contribution to the industry’s evolving needs.

Enhanced Strength and Lightweight Nature

Titanium alloys are renowned for their exceptional strength-to-weight ratio. Being approximately 30% stronger and 50% lighter than steel, they offer an optimal solution for aerospace components that demand high strength without the penalty of increased weight. This characteristic is crucial for improving fuel efficiency and payload capacity in aircraft design.

Outstanding Temperature and Corrosion Resistance

Another significant advantage is their excellent resistance to high temperatures and corrosion. Titanium alloys maintain their structural integrity and mechanical properties even when exposed to extreme conditions, making them ideal for critical aircraft components such as engine parts and exhaust systems that operate under high thermal stress.

Durability and Longevity

The durability of titanium alloys contributes to their longevity, reducing the need for frequent replacements. This durability is particularly beneficial for aerospace applications where reliability and safety are paramount. Components made from titanium alloys can withstand the rigors of aerospace operations, ensuring long-term performance and structural integrity.

Applications in Aerospace Manufacturing

| Component | Application |

|---|---|

| Engine Parts | High-temperature resistance and strength for optimal engine performance. |

| Exhaust Systems | Corrosion resistance and durability in harsh operating conditions. |

| Landing Gear | Strength-to-weight ratio for reduced aircraft weight and improved efficiency. |

| Airframe Components | Structural integrity and resistance to environmental factors. |

In conclusion, the adoption of titanium alloys in aerospace manufacturing offers a competitive edge, enhancing the performance, efficiency, and safety of aircraft. Their unparalleled strength, lightweight nature, and resistance to harsh conditions make them an indispensable material in the aerospace industry.

The Larger Impact: How Titanium Alloys Enhance Aerospace Technology

Titanium alloys have significantly improved modern aerospace technology, proving beneficial in terms of cost-efficiency and overall performance. Despite the higher initial cost associated with these robust materials, their long-term benefits cement them as a cost-effective option for manufacturers due to reduced replacement expenses. This is thanks to titanium’s exceptional durability which minimises the need for frequent maintenance or part changeovers.

- Cost-Efficiency: Analysis has shown that while sourcing and processing titanium may be more expensive upfront, its long-lasting nature offers substantial savings over time. Aircraft components made of titanium typically have longer operational lifespans compared to those from other materials. They also resist corrosion better reducing the necessity for routine replacements, thus contributing to significant cost reductions in the long term.

- Better Performance and Safety: The advantages of titanium extend beyond cost-related aspects. Its superior strength-to-weight ratio means aircraft can afford to carry heavier payloads without compromising speed or fuel efficiency. As far as safety is concerned, one case study showcases how planes manufactured using titanium alloys encountered fewer structural issues, resulting in safer operations and boosted confidence among consumers.

All these factors illustrate the larger impact of titanium alloys on enhancing aerospace technologies, making it an invaluable resource in this sector.

Other Articles You Might Enjoy

- The Advantages of Titanium Alloys in Aerospace Manufacturing

The Advantages of Titanium Alloys in Aerospace Manufacturing Aerospace manufacturing is an industry involved with the design and production of both aircraft and spacecraft. It encompasses two main sectors, aeronautics…

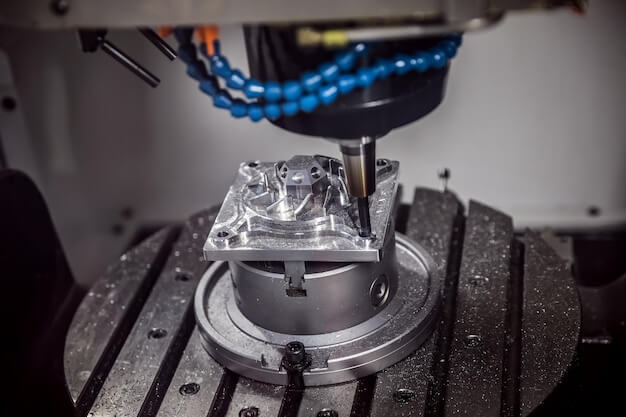

- CNC Machining for Aerospace: Titanium vs. Aluminum Alloys Comparison

CNC Machining in Aerospace Industry: Material Choice Significance CNC machining, an abbreviation for Computer Numerical Control machining, is a process utilized extensively in the aerospace sector. The technology relies on…

- Titanium is used in the production of medical and aerospace instruments.

Unique Properties of Titanium Titanium, a lustrous transition metal with a low density and high strength, stands out for its remarkable resistance to corrosion and ability to withstand extreme temperatures.…