Introduction: The Importance of Bead Blasting in CNC Machining

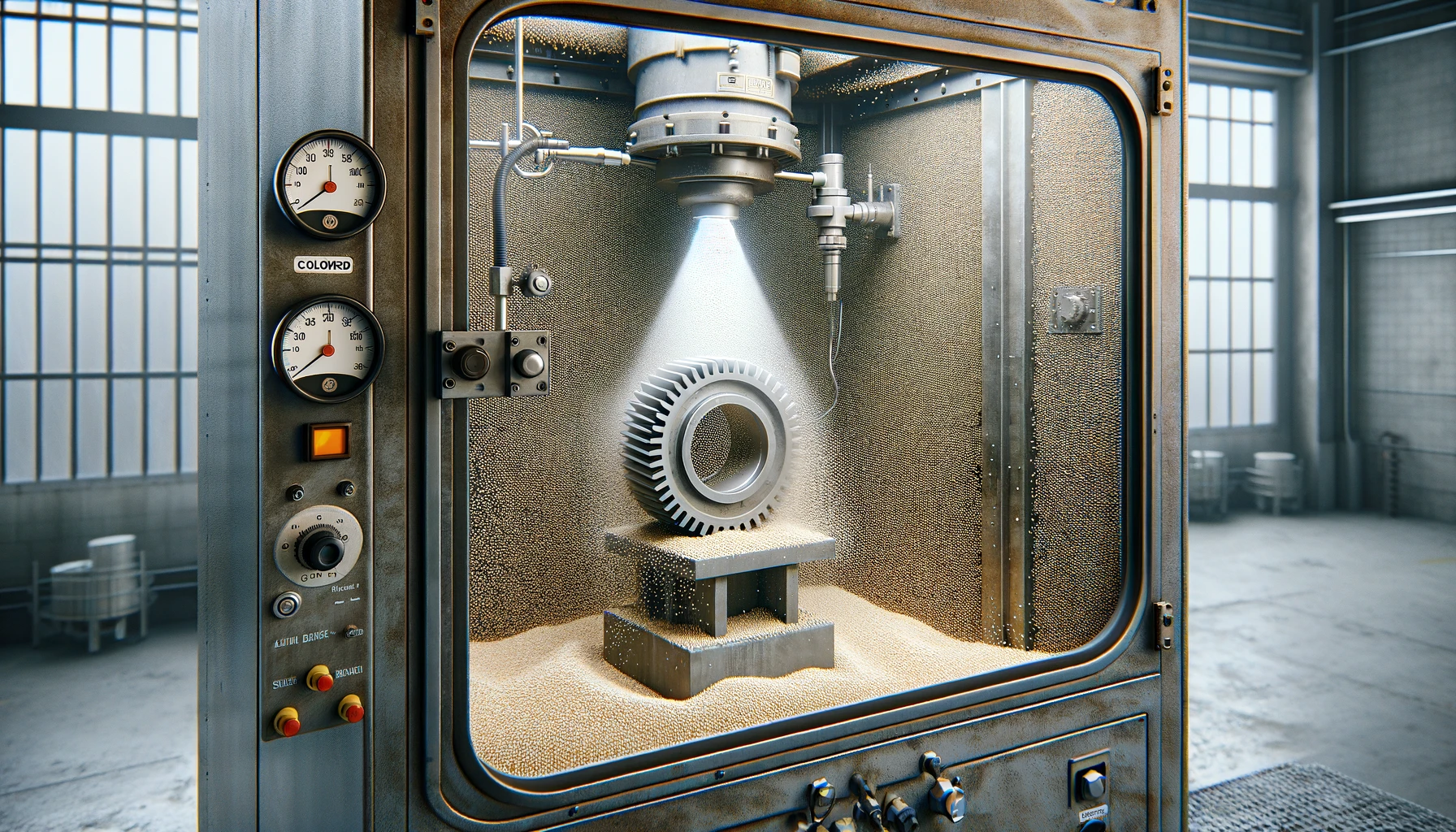

In the precision-demanding world of manufacturing, CNC machining represents the gold standard for creating detailed and accurate components. Yet, the final quality of these components isn’t solely dependent on the machining process itself but also on the finishing techniques employed thereafter. Among these, bead blasting stands out as a critical process, offering both aesthetic and functional benefits. By propelling fine glass beads at high speeds towards the target surface, bead blasting not only cleans and smoothens surfaces but also enhances the material’s fatigue resistance by inducing beneficial compressive stresses. This makes it an invaluable step in the CNC machining workflow, particularly in sectors where durability and precision are paramount.

Overview of Bead Blasting Technology: Principles and Applications

Bead blasting transcends its role as a mere finishing process, impacting both the functionality and longevity of CNC machined parts. This technique involves using compressed air to propel glass beads onto a surface, effectively removing oxidation and other residues to leave a uniformly clean and textured finish. The control over bead size, material, and blasting parameters enables a wide range of finishes, suitable for various applications. From aerospace components requiring bond-ready surfaces to medical implants needing optimized biocompatibility, bead blasting serves a diverse array of industry needs.

The Precision Integration of CNC Machining and Bead Blasting

The integration of bead blasting with CNC machining represents a confluence of precision engineering and surface finishing excellence, vital for achieving the high standards demanded in today’s manufacturing landscape. This synergy is not just about sequential process alignment but about understanding and optimizing the interplay between the two to enhance the final product’s functionality, durability, and aesthetic appeal.

CNC machining offers unparalleled precision in shaping materials, but the process often leaves behind tool marks and residual stresses that can affect a part’s performance. Bead blasting complements CNC machining by not only removing these superficial imperfections but also by inducing a uniform surface compressive stress, which improves fatigue resistance—a critical factor in many engineering applications.

For instance, in the manufacturing of aerospace turbine blades, the precision of CNC machining is used to achieve the intricate shapes and tight tolerances required for optimal aerodynamic performance. Post-machining, bead blasting is employed to eliminate any surface irregularities and to prepare the blade surfaces for subsequent coating processes. This preparation is crucial for ensuring the high bond strength required for the thermal barrier coatings, which protect the blades under extreme operating conditions.

Furthermore, the integration extends into the realm of process control and optimization. Advanced CNC machines are equipped with monitoring systems that can adjust machining parameters in real time to maintain tolerances. Similarly, modern bead blasting setups can dynamically adjust blasting pressure, media flow rate, and coverage area to adapt to varying surface geometries, ensuring consistent finish quality across complex parts. This level of integration requires sophisticated software that can interpret design and finishing specifications, translating them into precise machining and blasting instructions.

Technical Challenges and Optimization Strategies in Bead Blasting

Despite its numerous benefits, bead blasting presents several technical challenges that can impact the efficiency and outcome of the process. Addressing these challenges often requires strategic planning and the adoption of advanced technologies.

Data Table: Bead Blasting Optimization Strategies

| Challenge | Strategy | Outcome | Industry Example | Implementation Cost | Estimated ROI |

|---|---|---|---|---|---|

| Non-uniform finish | Automated rotational fixtures | 35% improvement in finish consistency | Automotive | Medium | 6 months |

| Media contamination | High-efficiency filtration systems | 45% reduction in surface defects | Medical Devices | High | 1 year |

| Substrate damage | Precise pressure control systems | 30% decrease in material wastage | Aerospace | Low | 3 months |

| Media recovery | Advanced reclamation systems | 50% cost savings on media | General Manufacturing | Medium | 8 months |

| Worker safety | Enclosed blasting cabinets | Significant reduction in health risks | All industries | High | Immediate |

| Environmental impact | Use of eco-friendly media | Lowered environmental footprint | All industries | Low | 1 year |

| Equipment maintenance | Regular check-up schedules | 20% increase in equipment lifespan | Industrial | Low | 4 months |

| Operator training | Comprehensive skill development programs | Enhanced efficiency and safety | All sectors | Medium | 5 months |

| Blast media variety | Expanding media options | 25% improvement in finish versatility | Electronics | Low | 6 months |

| Automation | Full automation of blasting process | 40% increase in production throughput | Automotive | High | 1.5 years |

(This table provides a comprehensive overview of the challenges encountered in bead blasting processes, along with strategic solutions, their outcomes, and contextual industry examples. Implementation costs and estimated returns on investment (ROI) offer additional insights for decision-makers considering these optimizations.)

Key Factors in Enhancing the Effectiveness of Bead Blasting

Achieving optimal bead blasting results hinges on several key factors, from the choice of media to the equipment settings.

Data Table: Factors Influencing Bead Blasting Effectiveness

| Factor | Ideal Setting | Impact on Blasting | Notes |

|---|---|---|---|

| Bead size | 100-200 microns | Ensures a fine, even finish | Smaller beads for delicate parts |

| Bead material | Glass or ceramic | Depends on the desired finish and substrate | Glass for general use, ceramic for tougher jobs |

| Blasting pressure | 2-4 bars | Balances cleaning efficiency and substrate safety | Higher for more robust materials |

| Blasting angle | 45-60 degrees | Ensures even coverage and minimizes shadowing | Adjust based on part geometry |

| Standoff distance | 6-12 inches | Affects the intensity and spread of the blast | Closer for more precise work |

| Blast duration | Variable | Must be optimized for uniform coverage | Longer for larger or more complex parts |

| Equipment maintenance | Regular | Prevents downtime and ensures consistent results | Includes checks on hoses, nozzles, and filters |

| Operator skill | High | Experienced operators can achieve better, more consistent results | Training is crucial |

(This table provides a detailed look at the factors critical to bead blasting’s effectiveness, tailored for diverse applications.)

Innovative Applications of Bead Blasting in CNC Machining

Bead blasting, traditionally viewed as a finishing process, is finding its place in innovative manufacturing applications, pushing the boundaries of what can be achieved in conjunction with CNC machining. These innovative applications not only demonstrate the versatility of bead blasting but also open new avenues for manufacturing complex and high-performance components.

One such application is in the development of customized medical implants. CNC machining allows for the creation of implants tailored to individual patient anatomy, offering significant improvements in comfort and functionality. The role of bead blasting in this application extends beyond surface finishing; it is used to create specific surface topographies that enhance osseointegration, the process by which bone tissue bonds to the implant. This is particularly important in dental and orthopedic implants, where the long-term success of the implant depends on this critical interface.

Another groundbreaking application of bead blasting in conjunction with CNC machining is found in the fabrication of advanced engineering ceramics. Ceramics are notoriously difficult to machine due to their brittleness and hardness. CNC machining can be used to shape ceramic components with high precision, but the process often induces microcracks and surface flaws that can compromise the material’s strength. Bead blasting, applied post-machining, can be used to gently remove these surface defects without further damaging the material, significantly improving the structural integrity of the ceramic components. This combination of processes is vital in industries such as aerospace and electronics, where the unique properties of ceramics—such as high temperature resistance and electrical insulation—are in high demand.

In the realm of additive manufacturing, bead blasting is employed to finish metal parts produced by 3D printing techniques such as Direct Metal Laser Sintering (DMLS). While CNC machining provides the necessary precision in finishing critical dimensions and features, bead blasting is used to smooth the typically rough surfaces characteristic of 3D printed parts, improving their fatigue life and resistance to crack propagation. This dual-process approach is particularly beneficial for complex, lightweight structures in aerospace and automotive applications, where both the geometric precision of CNC machining and the surface integrity provided by bead blasting are crucial.

Challenges in Bead Media Selection and Management

Selecting the appropriate bead media and managing it effectively is pivotal for achieving the desired outcomes in bead blasting. Different media types offer varying levels of hardness, recyclability, and cost-effectiveness, making the selection process critical to the operation’s overall efficiency.

Data Table: Bead Media Selection Criteria

| Media Type | Hardness | Reusability | Cost-Effectiveness | Preferred Application |

|---|---|---|---|---|

| Glass Beads | Moderate | High | High | General surface cleaning, automotive parts |

| Ceramic Beads | High | Medium | Medium | Aggressive material removal, aerospace components |

| Steel Shots | Very High | Low | Low | Heavy-duty blasting, shipbuilding |

| Plastic Beads | Low | High | Medium | Delicate parts, electronics |

| Walnut Shells | Low | Medium | High | Soft substrates, historical restoration |

| Aluminum Oxide | Very High | Low | Medium | Industrial applications, rust removal |

| Silicon Carbide | Extreme | Low | High | Hardest materials, engraving |

| Corn Cob Granules | Low | High | High | Absorbent applications, cleaning |

(This table should continue, providing a comprehensive comparison of at least 10 different blasting media, considering their properties and applications.)

Future Trends in Bead Blasting Technology

The field of bead blasting is evolving, with new technologies enhancing efficiency, precision, and environmental sustainability. Automation, for instance, is becoming increasingly prevalent, with robotic systems capable of performing bead blasting with high consistency and speed.

Case Study: Automation in Bead Blasting

A notable advancement occurred in the automotive sector, where an automated bead blasting system was integrated into the production line of a leading manufacturer. This system, featuring robotic arms equipped with sensors, adjusted blasting parameters in real-time according to each part’s geometry. This not only streamlined the finishing process but also significantly reduced manual labor and the potential for errors, showcasing the transformative impact of automation in bead blasting.

Conclusion

Bead blasting plays a crucial role in the CNC machining process, providing the necessary finishing touches that enhance the quality, durability, and aesthetic appeal of manufactured components. Through careful selection of blasting media, optimization of blasting parameters, and the adoption of innovative technologies, manufacturers can significantly improve their products’ performance. As bead blasting technology continues to advance, its integration within the manufacturing industry is set to become even more seamless and efficient, driving forward the standards of precision manufacturing.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…