Introduction to CNC Machining and Importance of Metals

CNC machining, or Computer Numeric Control machining, is a commonly utilized method in the manufacturing sector that involves the use of computers to control machine tools. These tools can range from lathes, mills, routers, and grinders. This technology, while advanced, simplifies complex processes which would otherwise require extensive human intervention.

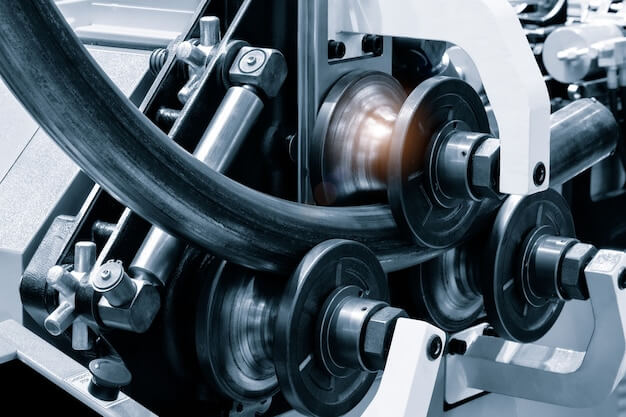

Metals play an integral role in this process due to their durability and reliable properties. They are easily machinable and robust, making them ideal for the exactitude requisite in CNC operations. The key benefits of using metals in CNC machining include:

- Tensile strength: Most metals have excellent resistance against tension and high compressive forces. This aspect makes them able to endure intense motorized movements without deformation.

- Machinability: Metals such as brass and bronze offer great machinability. Their material composition allows for precise, clean cuts with minimal tool wear.

- Heat resistance: Many metals exhibit superior thermal stability even under continuous operation, reducing any risk of overheated components during machining processes.

Understanding of Bronze and Brass

Bronze, an alloy composed primarily of copper and tin, is known for its excellent castability which makes it a prevalent choice in the realm of sculpturing. Exhibiting high levels of durability and corrosion resistance, bronze is frequently used for making coins, metalware, tools, as well as boat and ship fittings. Its ability to fill complex molds efficiently have garnered it an important role in artistry and design.

- Example: The highly valued ‘Lost Wax’ method in sculpture heavily relies on bronze due to its superior casting abilities.

In comparison, brass—an alloy mainly constituted by copper and zinc—is distinctively recognized for its acoustic properties. Additionally, brass’ golden aesthetic, smooth surface finish, and anti-microbial characteristics make it immensely popular in multiple industries – notably musical instruments’ production, architectural applications, gears, locks, bearings, doorknobs, electrical connectors amongst others. It not only serves functional purposes but also enhances the aesthetics of the product it’s employed in.

- Example: Trumpets, saxophones, trombones – all these musical instruments considerably leverage the exceptional acoustics of brass in their construction.

Comparison of Properties Between Brass and Bronze in CNC Machining

When comparing the properties of brass and bronze in CNC machining, several key differences emerge:

- Material Composition: Brass is an alloy of copper and zinc, often containing lead, manganese, iron, aluminum, and silicon, while bronze is an alloy of copper and tin, with additional elements such as nickel, aluminum, phosphorus, and zinc.

- Durability: Bronze is sturdier and more durable than brass, which is more vulnerable to splitting, cracking, and corrosion.

- Corrosion Resistance: Bronze forms a protective layer to prevent corrosion, while brass has lower corrosion resistance compared to bronze.

- Machinability: Copper exhibits better machinability compared to both brass and bronze, with copper being more flexible and easier to work with.

- Yield Strength: Bronze has a higher yield strength compared to brass and copper.

These differences are crucial considerations when selecting the appropriate material for CNC machining projects.

For precision machining services, consider using an online CNC service to ensure high-quality results.

Determining the Use Cases for Both Metals

Concisely, bronze and brass have unique properties that make them ideal choices for different use cases in CNC machining. Bronze offers a high level of corrosion resistance, strength, and durability which are paramount in industrial applications.

- Bronze: For instance, its hardness and anti-friction properties make it perfect for producing components such as gears and bearings used in heavy machinery, ship parts, or engineering tools. Additionally, due to its aesthetic appeal and ductility, architects and designers use bronze to fabricate ornaments, sculptures, medals, and coins.

- Brass: Brass on the other hand, owing to its machinability and versatility, is typically employed in the manufacture of architectural fittings like door knobs and handles, faucets, musical instruments – particularly wind ones like trumpets and saxophones, electrical fixtures, and precision equipment because it doesn’t create sparks when struck against hard surfaces.

Essentially, the choice between these two metals depends heavily on the required function, design, the need for decorative appeal, and the environment where the object will be used. Selecting the right material ensures quality performance and long-lasting lifespan of the end product.

Selection Criteria: Choosing Between Brass or Bronze for Your Project

In the realm of CNC machining, making a choice between using brass or bronze material is driven by several essential factors. First and foremost is tensile strength. High-strength materials like bronze can withstand pressure better and are less likely to rupture under stress, but that factor has to be balanced with cost where brass often presents a more economical option.

- Tensile Strength: The capability of the material to resist breaking under tension is critical in many applications. Bronze possesses higher tensile strength than brass which could influence decision-making when creating items subjected to high stress or pressure.

- Corrosion Resistance: Both metals show good resistance against corrosion, though their performance may vary depending on the specific environment they will be exposed to. For instance, brass is more resistant to freshwater while bronze fares well in seawater conditions.

- Cost: Although bronze might prove superior in some respects, its typically higher cost might make brass a more viable alternative especially for large scale production.

- Machinability: Brass comes on top when machinability is factored in. Its softness and malleability make it easier to shape, cut, and drill through, thereby achieving more intricate designs without posing too much strain on the machines.

All these factors interact and have an impact on your final product’s qualities such as durability, aesthetic appeal, functionality, and ultimately, manufacturing costs. Therefore, understanding these selection criteria is crucial in achieving optimal results from your CNC machining investment.

Other Articles You Might Enjoy

- Unraveling Bead Blasting in CNC Machining(die casting Agatha)

Bead blasting is a procedure that's widely used in the sector of Computer Numerical Control (CNC) machining. This process involves forcefully propelling a stream of abrasive beads under high pressure…

- Revolutionizing CNC Machining with Bead Blasting(die casting Laurel)

Bead blasting, as a critical aspect of modern manufacturing methods, can boost the overall quality and functionality of various components. This technique has proven incredibly beneficial in Computer Numerical Control…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…