Introduction to CNC Machining and its Environmental Considerations

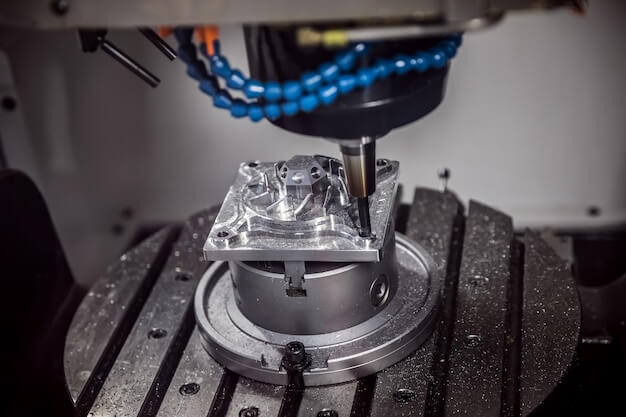

CNC machining is an advanced manufacturing process wherein pre-programmed software dictates the movement of factory machinery and tools. It is recognised for its precision, efficiency, and versatility in producing a wide array of objects ranging from car parts, surgical equipments to computer components. In spite of these innovations, the environmental footprint resulting from material selection in CNC machining cannot be ignored.

This article seeks to shed light on some of the key environmental considerations in CNC machining, focusing particularly on sustainable manufacturing practices. It delves into various aspects such as:

- The types of materials often used in this process and their environmental implications

- The concept of ‘Green’ or ‘Sustainable’ Manufacturing and its relevance in today’s industrial landscape

- Potential strategies to promote sustainability within CNC machining processes – including a look at recyclable materials and energy-efficient methods

A comprehensive understanding of these factors will not only allow us to leverage the benefits of CNC machining but do so in an environmentally responsible manner.

Understanding Sustainability in Manufacturing

Sustainable manufacturing can be defined as the creation of manufactured products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources. It also encompasses socially responsible practices for employees and stakeholders. In today’s highly competitive market, sustainability isn’t just a trend but an imperative aspect of daily operations due to mounting economic pressure and regulatory standards.

The importance of fostering sustainable measures breeds from two key benefits: substantial cost savings and positive brand image enhancement. Companies shifting towards sustainable manufacturing can significantly lower operational costs by optimizing their usage of materials and reducing waste. Besides this economical benefit, companies gain respectability and trust among consumers who hold an increasing preference for environmentally friendly businesses.

- Companies like Xerox and Toyota are prime examples of implementing such practices, introducing closed-loop recycling systems in their production process which have proven not only beneficial for the environment but for the bottom line as well.

Role of Material Selection in Sustainable CNC Machining

The selection of materials plays a pivotal role in sustainable computer numerical control (CNC) machining. The choice of material directly influences environmental considerations, such as energy consumption, waste generation, and recyclability. Therefore, manufacturers must carefully consider the type of material used to strike a balance between product quality, cost efficiency, and sustainability.

Several factors come into play when choosing materials for sustainable CNC machining. Firstly, it is essential to evaluate the material’s machinability—how easily it can be cut and shaped using CNC machines. Materials with high machinability require less power and time to process, promoting energy conservation. Secondly, we should consider the lifespan and durability of the selected material. Longer-lasting materials reduce the need for frequent replacement, thereby saving resources. Lastly, the recyclability or reusability of the material is another vital aspect to ponder upon. Using recyclable materials minimizes waste generation, boosting sustainability efforts.

For instance, let’s compare metals and plastics. Metals, like steel or aluminium, tend to have better machinability, longevity, and are typically more recyclable than most plastics. However, they often need more energy for processing, hence increasing carbon footprints. On the other hand, certain types of plastic may consume less energy during machining but contribute significantly to waste due to their limited recyclability. Hence, this comparative example underscores how crucial careful material selection is for sustainable CNC machining.

Environmental Impacts of CNC Machining Materials

The choice of materials in CNC machining can have significant environmental impacts. Here are some key considerations:

1. Material Extraction

The extraction of raw materials for machining can have adverse environmental effects. Mining and extraction processes can lead to habitat destruction, soil erosion, water pollution, and greenhouse gas emissions. Choosing materials that have a lower environmental impact in their extraction phase can help mitigate these effects.

2. Energy Consumption

CNC machining requires energy to power the machinery and tools. The energy source used can have varying environmental impacts. For example, using renewable energy sources such as solar or wind power can reduce the carbon footprint associated with machining processes.

3. Waste Generation

CNC machining generates waste in the form of excess material and cutting fluids. Proper waste management practices, such as recycling and proper disposal, are essential to minimize the environmental impact. Additionally, selecting materials that generate less waste during machining can help reduce overall waste generation.

4. Chemical Usage

Chemicals, such as cutting fluids and surface treatments, are often used in CNC machining processes. These chemicals can have environmental implications if not properly managed. Choosing environmentally friendly alternatives or optimizing chemical usage can help minimize the environmental impact.

Considering the environmental impacts of CNC machining materials is crucial for sustainable manufacturing practices. By selecting materials with lower extraction impacts, optimizing energy consumption, managing waste effectively, and minimizing chemical usage, manufacturers can contribute to a more environmentally friendly CNC machining process. To learn more about sustainable manufacturing practices and CNC machining services, you can explore the Blog provided by our trusted partner.

Strategies for More Environmentally-Friendly Material Selection

In the CNC machining industry, shifting towards more sustainable manufacturing practices is crucial to reduce environmental impact. A significant step in this process is environmentally-friendly material selection. Here are some tips that can help make a more eco-friendly material decision:

- Analyze Material Impact: Assessing the environmental consequences of each material type beforehand aids in selecting those with the least impact.

- Favor Recyclability: Opt for materials which can be reused or recycled easily and maintain their properties even after going through the recycling process.

- Trend Towards Sustainability: Consider sustainably sourced materials for your project that ensure durability while lessening harm to the environment.

A noteworthy practice is transitioning from virgin steel to its recycled equivalent for usage in CNC machining. Using virgin steel has considerable costs both economically and ecologically since it involves resource-intensive mining operations. Conversely, employing recycled steel not only reduces waste accumulation, but also significantly cuts down on energy consumption – making it an excellent solution to increase sustainability in CNC machining processes.

Benefits and Challenges of Implementing Sustainable Practices in CNC Machining

Implementing sustainable practices in Computer Numerical Control (CNC) machining can yield a number of potential benefits, including economic advantages and an improved brand image. Sustainability initiatives often lead to cost savings over time as a result of enhanced operational efficiencies and reduced material waste. Moreover, companies that prioritize sustainability can enhance their reputation among consumers who are increasingly seeking out businesses committed to reducing their environmental impact. This commitment invariably supports the strengthening of customer relationships.

- Economic Benefits: The adoption of sustainable materials and processes in CNC machining can generate significant long-term cost reductions. Efficient use of materials cuts down on waste, thereby reducing expenses associated with material procurement and disposal. Furthermore, sustainable manufacturing processes tend to be energy-efficient, which translates into additional cost savings.

- Improved Brand Image and Customer Relationships: An increasing number of customers prefer doing business with eco-friendly brands. By prioritizing sustainability in its CNC machining operations, a company can position itself as environmentally responsible, enhancing its appeal amongst these consumers and fostering strong customer relationships.

Despite these advantages, there are challenges to implementing sustainable practices. A major hurdle is initial cost implementations as transitioning towards green manufacturing techniques might require substantial upfront investment for newer, more efficient equipment or technologies. Additionally, sourcing sustainable materials may prove tricky since availability isn’t always guaranteed.

- Cost Implementations: Upgrading machinery and adopting new technologies to comply with sustainable standards involves significant capital expenditure. Companies will need solid financial planning to offset these costs while ensuring uninterrupted manufacturing.

- Availability of Sustainable Resources: The huge demand for sustainable resources sometimes outpaces supply, making it difficult for manufacturers to source them reliably. Moreover, some geographical regions might not have easy access to certain sustainable materials, further complicating procurement.

Other Articles You Might Enjoy

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…

- CNC Machining for Medical Applications: Compliance and Material Selection?

Introduction to CNC Machining in Medical Applications CNC or Computer Numerical Control machining is a manufacturing process wherein pre-programmed computer software dictates the movement of factory tools and machinery. This…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…