CNC Machining and Material Selection in Extreme Environments

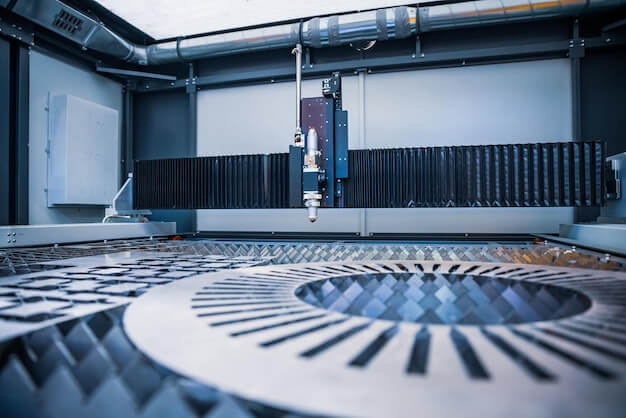

The process of Computer Numerical Control (CNC) machining involves a computer-aided design to control the complex movement of machinery. This technology is utilized across various industries, transforming raw material into custom-made parts with high precision. It’s important to note that selecting appropriate materials for CNC machining becomes critically central when machines are operating under extreme conditions such as excessive heat or corrosive environments.

For instances, materials like stainless steel, titanium, or Inconel have properties that can withstand high temperatures and resist corrosion, thus making them ideal choices for such harsh scenarios. A few key factors while choosing durable materials include:

- Tolerability against high heats

- Resistance to wear and tear

- Machinability

- Cost-effectiveness

Selecting suitable materials not only enhances the product’s reliability, but also extends its lifecycle, reduces maintenance costs and ensures optimal execution, irrespective of the working environment.

Understanding Extreme Environments for CNC Machining

In the context of CNC machining, extreme environments refer to conditions that expose machine parts and materials utilized in manufacturing processes to extremely high temperatures or corrosion. High heat may result from intense friction generated during rapid metal cutting operations, leading to thermal expansion, warping, and distortion of elements. On the other hand, corrosive environments are site-specific and could be as a consequence of proximity to oceanic regions, chemical factories, or due to internal factors such as acidic coolants used within machines. Both heat and corrosion significantly impact the lifespan and performance of CNC machinery.

- Heat:Materials should possess superior thermal resistance because extreme temperatures can alter their physical properties, rendering them structurally fragile and less effective.

- Corrosion:This factor is intricately linked with wear resistance. Materials exposed to corrosive atmospheres must showcase excellent resistance to rusting, pitting, crevice corrosion, and stress-corrosion cracking to maintain their form integrity.

The use of appropriate heat-resistant alloys or ceramics, stainless steel variants, or other anti-corrosive materials helps increase machine durability under taxing operational circumstances.

Factors Influencing Material Selection for CNC Machining in Extreme Environments

When selecting materials for CNC machining in extreme environments, several critical factors must be considered to ensure optimal performance. Firstly, durability is paramount – the material needs to withstand harsh conditions without compromising its structural integrity or functionality. Secondly, attention should be paid to the material’s melting point. It is crucial to choose a material with a high enough melting point that it won’t become distorted or weakened under intense heat.

- Durability: For instance, stainless steel exhibits remarkable durability gaining popularity in industries like aerospace and medical devices. Its resistance to wear and tear makes it suitable for long-term application in demanding environments.

- Melting Point: Titanium is an example of a material with a high melting point. This characteristic lends itself well to applications involving high temperatures, such as jet-engine components or parts used in oil & gas exploration rigs.

These elements all play a central role in determining how well a chosen material will perform when subjected to adverse conditions typical of extreme environments. Therefore, careful selection based on these parameters can increase efficiency and lifespan of CNC machined parts, leading to cost savings and improved operational outcomes in the long run.

Types of Materials Used for Heat and Corrosion Resistance in CNC Machining

When it comes to CNC machining in extreme environments, selecting materials with excellent heat and corrosion resistance is crucial. Here are some types of materials commonly used for these purposes:

1. Stainless Steel:

- Stainless steel is a popular choice for CNC machining due to its high resistance to heat and corrosion.

- It contains chromium, which forms a protective oxide layer that prevents rusting and enhances heat resistance.

- Various grades of stainless steel, such as 316, 303, and 304, offer different levels of heat and corrosion resistance, allowing for customization based on specific requirements.

2. Titanium:

- Titanium is known for its exceptional strength, low density, and excellent resistance to heat and corrosion.

- It is often used in aerospace and medical industries where extreme environments are encountered.

- Titanium alloys, such as Ti-6Al-4V, provide even higher strength and heat resistance, making them suitable for demanding CNC machining applications.

3. Inconel:

- Inconel is a family of nickel-based alloys known for their outstanding resistance to high temperatures, oxidation, and corrosion.

- These alloys maintain their strength and structural integrity even in extreme heat and harsh environments.

- Inconel alloys, such as Inconel 625 and Inconel 718, are commonly used in CNC machining for applications requiring exceptional heat and corrosion resistance.

4. Aluminum Alloys:

- Aluminum alloys, such as 6061 and 7075, offer good heat resistance and corrosion resistance.

- They are lightweight and have excellent thermal conductivity, making them suitable for applications where weight reduction and heat dissipation are important.

- Aluminum alloys are commonly used in CNC machining for aerospace, automotive, and electronics industries.

By selecting materials with superior heat and corrosion resistance, CNC machining can be effectively performed in extreme environments. To access professional CNC machining services and expert advice on material selection, you can rely on our online CNC service.

CNC Machining in Extreme Environments

In the context of CNC machining, extreme environments refer to conditions with intense heat or corrosive elements. Operating under these harsh conditions necessitates intelligent material selection and meticulous crafting processes for optimal functionality and durability. Materials used are prominently those boasting high tolerance to heat and corrosion like Inconel, Stainless Steel, Tungsten and Titanium alloys.

- Inconel: Known for its resistance against oxidation and ability to maintain structural integrity at elevated temperatures.

- Stainless Steel: Chosen for its ability to resist rust, allowing it to thrive in both highly acidic and basic environments.

- Tungsten: Its outstanding hardness accommodates high-pressure applications while maintaining a low thermal expansion rate.

- Titanium Alloys: Favoured for their superior strength-to-weight ratio, aiding lighter machinery without compromising sturdiness and performance.

An example showcasing this process can be found in the aerospace industry. Jet engine components or rocket parts, often exposed to aggressive chemical reactions due to combustion and extremely high operating temperatures, are produced using robust materials via arduous CNC machining to withstand such challenging environments.

Challenges Faced During CNC Machining in Extreme Environments

CNC machining, a tool employed broadly across different industries for precise manufacturing of components, faces various challenges when operating under extreme heat or corrosive conditions. Primarily, the harsh environment can lead to increased wear and tear on machine parts, subsequently affecting the integrity and quality of finished products. Additionally, the respective temperatures can cause thermal distortion – unwanted deformation due to temperature changes – that may dramatically impact the accuracy of intricate tasks. Further complications include mobility issues owing to altered viscosity of oil-based lubricants and coolant evaporation problems.

To overcome these obstacles, material selection becomes paramount. This includes choosing substance with high resistance against deterioration induced by corrosion and ultra-high temperatures. An array of heat-resistant superalloys – like Inconel or titanium alloys – offer robust solutions because of their extraordinary mechanical strength and resistance to thermal creep deformation. Furthermore, implementing advanced cooling systems adds an additional line of defence against overheating. Likewise, utilization of synthetic coolants or modification of coolant application methods represents a worthwhile solution for limits imposed onto fluid power efficiency by rising temperatures. For instance, employing force-fed lubrication system could serve as a significant alternative in such state.

Final Considerations when Selecting Materials for CNC Machining in Extreme Environments

In selecting materials, several considerations must be kept at the forefront before making a final decision. The first and foremost factor is cost – it’s important to understand that while some materials may have superior heat or corrosion resistance, they could also potentially drive manufacturing costs sky high. Second is availability – not all materials are equally accessible across different geographic locations. Thus, choosing an overly rare material could lead to supply chain issues down the line.

- Moreover, considering properties such as thermal conductivity, melting point, strength, weight, and hardness can significantly impact the machining process and ultimately, the performance of the finished product.

- Finally, regulations should also be considered – certain materials may have restrictions on their use due to health hazards or environmental concerns.

Above all, appropriate selection plays a crucial role in effective and efficient manufacturing. Being knowledgeable about each component’s function alongside understanding the demands of your specific application will culminate in a successful choice suitable for extreme conditions. For instance, Inconel is frequently used in jet engines and gas turbines because of its excellent oxidation and corrosive resistance at high temperatures.

Other Articles You Might Enjoy

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- CNC Machining for Consumer Electronics: Material Selection for Heat Dissipation

Introduction to CNC Machining in Consumer Electronics CNC machining stands as a pivotal technology in the manufacturing of consumer electronics, offering precision and efficiency in producing components. This process involves…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…