Introduction to CNC Machining and its Relevance in Manufacturing

CNC (Computer Numerical Control) machining, a mainstay in modern manufacturing, revolutionizes the process of creating complex parts from various materials. This sophisticated technology relies on pre-programmed computer software that dictates the movement and operation of factory machinery and tools, streamlining production processes like drilling, boring, and milling. Especially when producing custom titanium parts, this method guarantees precision, cost-efficiency, and speed.

- Precision: With the ability to follow highly specific digital templates, CNC machining ensures the creation of intricate designs with increased accuracy.

- Cost-Efficiency: Due to less manual labor required, fewer fabrication errors and efficient use of raw material, substantial cost savings can be realized through CNC machining.

- Speed: Given the automated nature of CNC machines, they work continuously without downtime leading to faster production times.

In essence, CNC machining has undeniably become indispensable for industries needing durable, high-strength components like aerospace, automotive, or medical where custom titanium parts are frequently required.

Basics of Titanium

Titanium, a highly desirable metal in various industries, boasts numerous qualities and physical attributes that enhance its appeal. It is renowned for being strong yet light weight, as well as resistant to corrosion even by sea water or chlorine, which makes it an ideal material choice for demanding applications such as aerospace, military equipment, and medical devices. Most importantly, titanium has the highest strength-to-weight ratio of any known element, allowing manufacturers to design products that are sturdy without having to contend with excessive weight.

- The Aerospace Industry: Due to its high strength-to-weight ratio, low density, and significant resistance to heat and corrosion, titanium is commonly used in aircraft structures and engines. The ability of this metal to withstand extreme conditions enables safe air travel and durability of parts.

- The Military Equipment Manufacturing: Owing to its robustness and lightweight, titanium forms an essential part of underwater vessels, missiles, and protective armor designs where endurance under strenuous situations is paramount.

- In Medical Field: Its hypoallergenic properties and biocompatibility make titanium exceptionally suitable for manufacturing artificial limbs and surgical instruments, enhancing patient care worldwide.”

To conclude, each industry uniquely harnesses the versatile traits of titanium, affirming its importance in diverse sectors.

Concept of Custom Parts Manufacturing

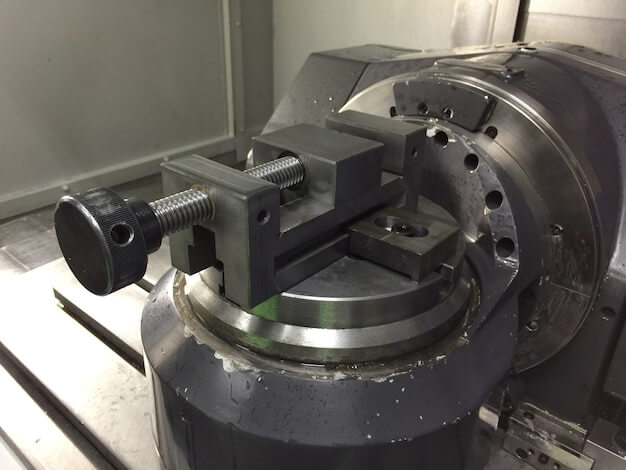

The process of custom parts manufacturing generally entails the creation of unique, tailor-made components designed to meet specific use-cases and specifications. This is made possible through a variety of advanced techniques in CNC machining, including milling, drilling, turning, and other subtractive methods. One major benefit of this approach is that it allows for high precision and excellent repetition accuracy when producing both small scales or bulk orders.

A practical example illustrating the role of custom parts can be seen in the automotive industry. Take for instance a racing car component; these pieces require extremely precise dimensions and complex shapes to optimize performance on the track. Often made from durable materials like titanium, such custom-manufactured parts uphold rigorous standards while meeting the exact requirements of the particular model.

- Milling: A cutting process where the machine tool removes undesired material by rotating a cutting tool with multiple sharp teeth.

- Drilling: Process wherein holes are created within a workpiece using a drill bit.

- Turning: The operation that involves rotation of the workpiece while the cutting tool moves in a linear motion.

The Role of CNC Machining in Creating Custom Titanium Parts:

- Applications of Titanium in CNC Manufacturing: Titanium is commonly used in high-performance aerospace parts, military components, and biomedical products such as implants.

- Advantages of Using Titanium in CNC Manufacturing: Titanium alloys have exceptional strength-to-weight ratios, making them lightweight and strong. They are also corrosion-resistant, have good heat conductivity, and are biocompatible, making them suitable for biomedical applications.

- Drawbacks of Using Titanium in CNC Manufacturing: Titanium has poor electrical conductivity and is difficult to machine. Regular HSS or weaker carbide cutters are not suitable for machining it, and it is an expensive material to use in CNC manufacturing.

- Properties and Industries Suitable for Titanium in CNC Machining: Titanium has an excellent strength-to-weight ratio, corrosion resistance, chemical resistance, and temperature resistance. It is suitable for specialized industries such as aerospace and medical.

Affordable CNC Machining Process for Titanium

The use of Computer Numerical Control (CNC) machining in the production of custom titanium parts has radically redefined cost-efficiency terms in manufacturing. This process benefits from a decreased need for manual labor, leading to reduced operational expenses and fewer errors that result in waste. Furthermore, this system excels at creating complex shapes and designs which would be resource-intensive with other techniques, translating into considerable cost savings.

Clients or end-users reap significant advantages through this affordability. For instance:

- Reduced upfront costs allow businesses to invest in more top-quality titanium machinery components without draining financial resources excessively

- Being able to afford precision-engineered elements enhances product performance while reducing maintenance and replacement intervals, conducing overall to long-term savings

- The economical nature of CNC machining enables small-scale productions runs, especially beneficial for start-ups and companies hoping to test prototype parts without making hefty commitments

.

In conclusion, the affordable CNC machining process for titanium marries quality and cost-effectiveness seamlessly, imparting clear dividends to both manufacturers and customers.

Factors Making CNC Machining More Cost-Efficient

Advanced technological developments in the manufacturing industry have made CNC machining an immensely efficient and cost-effective process. First and foremost, the element of high precision that accompanies this method significantly reduces errors, saving considerable costs on wasted material and rework time. The automation of CNC machines translates into a significant reduction of waste – a characteristic particularly beneficial for costly materials like Titanium. Automation minimizes human interaction with parts, reducing chances of error and enhancing uniformity and consistency among individual components.

CNC machinery also promotes efficiency by allowing ‘lights out’ production; essentially enabling 24-hour operation without breaks or downtime. For example, a case study conducted on a leading aerospace company illustrated vast improvements after incorporating CNC technology in their process line. The said discreet manufacturer realized savings up to 35% from reduced wastage and improved workflow efficiencies. Apart from these tangible benefits, the ability to produce custom titanium parts based on digital files eliminates the necessity for physical templates, further demonstrating the afforability and versatility of this revolutionary technique.

Choosing a CNC Machine for Titanium Parts Manufacturing: Key Considerations and Common Misconceptions

Selecting suitable Computer Numerical Control (CNC) machinery for titanium parts manufacturing requires careful thought, with numerous crucial factors demanding attention. For optimal precision, high spindle speeds are desirable for cutting velocity with rigidity in structure being fundamental to withstand the extreme pressures induced by titanium machining.

- Machine Tool Power & Stability: A potent machine tool will provide ample power and accuracy.

- Coolant Delivery: Efficient coolant delivery is vital in preventing titanium’s heat from damaging the tool or part.

- Type of Cutting Tools: Hard Metals require specific coatings on their tools like AlTiN to reduce wear and improve surface finish.

A common misconception concerning CNC machines for titanium parts production is that cost always translates into quality; a more expensive unit is not invariably superior or more efficient. The most sensible approach is to prioritize features pertinent to specific requirements rather than being swayed by price alone.

Conclusion

In conclusion, affordable CNC machining emerges as the perfect fit for custom titanium parts production due to a plethora of reasons. Its precision and speed, coupled with its ability to handle complex designs efficiently, make it incomparable in dealing with such sturdy material like Titanium. This technology effortlessly shapes and cuts materials which are usually too challenging to manipulate, ensuring consistent high-quality output every time.

- CNC machining’s programmability also heightens repeatability while minimizing human errors, therefore establishing itself as an economical solution in the long run.

- The unique aspect of cost-effective scalability offered by CNC machining further makes it stand out in the sphere of mass production scenarios where consistent quality assurance is pivotal.

- A vital factor contributing to its widespread admiration is that CNC machining needs minimal crew intervention post-set up, i.e., reduced dependency on manual labor, ensuring operational continuity even during challenging times.

- In essence, the blend of affordability, accuracy, versatility, and efficiency sets CNC machining as the ideal choice when working with robust materials like titanium.

FAQs on Affordable CNC Machining for Custom Titanium Parts

In response to numerous inquiries, we’ve compiled some of the most common questions around affordable CNC machining for custom titanium parts. Firstly, many ask if the affordability compromises quality- the simple answer is no, with advancements in technology, we have streamlined our operations to maintain high standards while reducing costs. Another recurrent question revolves around turnaround time; typically, depending on the complexity and number of parts required, production can take anywhere from 3 days to 2 weeks. Clients are also interested in knowing if we offer a range of finishes- indeed, we do! This includes but is not limited to basic as-machined finnish or coated finished like ceramic coatings or powder coat. Clarification has been sought about permissible order sizes; remarkably, there’s great flexibility here allowing both small and large scale orders. Lastly, concerns about precision are understandable – rest assured, digital sophisticated methods applied ensure exceptional accuracy within ±0.005″.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…