Introduction to CNC Machining

Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated production of complex parts. This technology utilizes computerized controls and machine tools to remove layers of material from a stock piece, known as the workpiece, transforming it into a specified design. The importance of CNC machining in today’s manufacturing landscape cannot be overstated. It allows for high precision, repeatability, and efficiency in producing parts, ranging from simple to highly complex geometries. For example, in the aerospace industry, CNC machining is crucial for creating intricate components that meet strict tolerance and material specifications.

- Precision: Achieves high accuracy in dimensions and shapes.

- Repeatability: Ensures consistent production quality, even over large volumes.

- Efficiency: Reduces production time and material waste.

Understanding Multi-Material CNC Machining

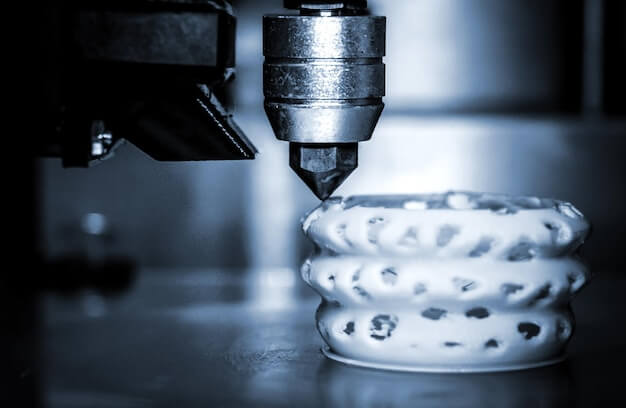

Multi-material CNC machining is a process that combines various materials into a single manufacturing sequence, allowing for the creation of complex parts with diverse properties. Unlike traditional single-material machining, which limits the component to one type of material, multi-material CNC machining leverages the strengths of different materials to enhance the functionality and performance of the final product. For example, a part could be designed with both metal for its strength and plastic for its flexibility, precisely machined in one process. This approach not only streamlines manufacturing but also opens up new possibilities in design and functionality that are not achievable with single-material processes.

- Definition: A method that integrates multiple materials into one continuous machining process.

- Contrast: Offers more design flexibility and functional integration compared to single-material machining.

- Example: Combining metal and plastic in a single part for both strength and flexibility.

Common Challenges in Complex Part Design

Designing complex parts presents a myriad of challenges, primarily due to the intricate geometries and the need for precise tolerances. One significant hurdle is the limitation imposed by materials. Not all materials are suitable for every design, and some can restrict innovation due to their physical properties, such as strength, flexibility, or temperature resistance. For instance, creating a part that requires both high strength and flexibility might be challenging if the available materials only offer one of these properties. This necessitates a careful selection of materials and sometimes leads to the use of multi-material CNC machining to meet the design requirements. Additionally, the complexity of a part can increase the difficulty of manufacturing it, leading to higher costs and longer production times. These challenges require designers to have a deep understanding of both the materials they are working with and the manufacturing processes involved.

- Material limitations restricting design innovation

- Increased manufacturing difficulty and costs

- Longer production times due to complex designs

Advantages of Multi-Material CNC Machining

Multi-material CNC machining offers the advantage of creating complex part designs with a combination of different materials. This approach allows for the integration of diverse material properties into a single component, enhancing functionality and performance. The ability to combine materials such as metals, plastics, and composites in a single CNC machining process provides flexibility in achieving intricate designs and meeting specific application requirements.

Real-World Example of Multi-Material CNC Machining

A notable case study demonstrating the advantages of multi-material CNC machining involves the production of aerospace components. These components often require the integration of various materials to meet strict performance and durability standards. For instance:

- Material Integration: Aluminum for its lightweight properties, titanium for strength at high temperatures, and composites for durability.

- Design Challenges: Achieving the optimal balance between weight and strength, while ensuring the component can withstand extreme conditions.

- Solution: Multi-material CNC machining allowed for precise control over the fabrication process, enabling the creation of components that met all design and performance criteria without compromising on any single aspect.

This approach significantly streamlined the manufacturing process, reducing both time and costs associated with producing complex aerospace components. It exemplifies how multi-material machining provides effective solutions to intricate design challenges.

Other Articles You Might Enjoy

- Exploring Bead Blasting In CNC Machining(cnc cutting tools Hale)

Bead blasting is a crucial technique applied extensively in the realm of Computer Numerical Control (CNC) machining. This process transforms the exterior aesthetics and surface quality of machined parts, augmenting…

- Comparing Machinability of Various Tool Steels: What's the Best Choice?

Understanding Tool Steels and their Machinability Tool steels are referred to as an extensive variety of carbon and alloy steels known for their distinctive hardness, abrasion resistance, and ability to…

- Understanding Bead Blasting in CNC Machining(cnc cutting tools Miles)

CNC machining is a manufacturing process known for its precision and versatility. One important aspect of this process that contributes significantly to both its functionality and finish quality is bead…