Amongst various surface finish techniques used in the manufacturing industry, bead blasting holds a significant place for its exceptional functionality mounted with an aesthetic appeal. This technique is widely employed in industries using computer numerical control or CNC machining. The process involves propelling beads at high velocity on to the material’s surface, usually through compressed air or suction mechanisms.

Using bead blasting in CNC machining doesn’t just lend to aesthetic precision but often accomplishes essential practical requirements like prepping the surface for coating applications or cleaning the pieces post fabrication. To appreciate this technique better and incorporate it more effectively, let’s explore its methodology, advantages, and limitations.

Bead Blasting Methodology

This procedure relies on the simple concept of friction caused by bead bombardment that erodes unwanted materials from the surface. Depending on the outcome sought, different types of abrasive media are released under controlled pressure onto the metal object. Glass, ceramic, plastic, or even walnut shells can be chosen as blasting mediums, each having their distinct properties and usages.

Glass beads give a satin sheen look without altering the dimensional structure of the workpiece. They’re ideal for creating smoother surfaces with less friction. On the other hand, harder materials like ceramics cater to aggressive grinding needs required while dealing with toughened alloys or castings.

Application In CNC Machining

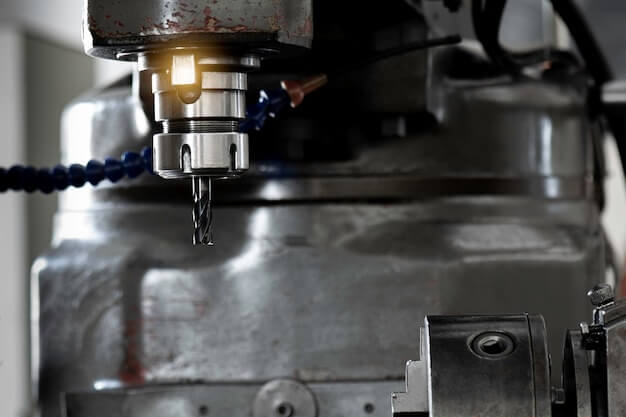

In CNC machining, which entails cutting a piece from larger raw blocks material accurately based on 3D CAD models, bead blasting becomes pertinent when seeking improved mechanical properties, ease of manufacture, cost-effectiveness, and superior aesthetics.

Abrasive blasting helps remove parting lines, machine marks, or burrs leftover post-machining processes. It readies the components smoothing any imperfections before they proceed towards electroplating or powder coating procedures. Here bead blasting guarantees better adhesion due to enhanced surface texture.

Advantages Of Bead Blasting

Deploying bead blasting comes with a host of benefits. To start, it is cost-effective as the machines require less power than conventional milling or turning processes used for surface finishing applications. It guarantees minimal material removal ensuring dimensional integrity while performing uniformly even on complex geometries.

With closed-loop systems recycling most blast media reducing environmental impact and easy automation possibilities ramping efficiency, bead blasting becomes an appealing choice in CNC machining operations. Moreover, its versatility extends from removing tough contaminations like rust or scale build-ups to finely polishing delicate surfaces promoting aesthetic superiority.

Limitations of Bead Blasting

While this method proves advantageous in numerous ways, operators should also consider certain limitations attached. Very thin-walled parts risk deformations due to high-pressure blasts that must be cautiously monitored. Further, abrasive dusts pose health hazards necessitating personal protective measures and proper housekeeping practices post-blasting.

Materials too hard or with poor malleability can sign up for cracks if subjected to strain exceeding their fracture limit. Lastly, finding ideal parameters such as right pressure, feed rate, blast medium size, nozzle angle etc., needs expertise thwarting trial errors costing time and resources.

Conclusion

In conclusion, incorporating bead blasting in the process chain enhances CNC machining outcomes by offering improved functionality and aesthetics to machined parts. As technology strides faster toward integrated manufacturing ecosystems, including such innovative processes helps companies stay competitive and fulfil varying consumer demands. Adequately understanding how bead blasting operates allows more calculated usage extracting optimal benefits out of your machining projects.

Other Articles You Might Enjoy

- Unraveling Bead Blasting in CNC Machining(die casting Agatha)

Bead blasting is a procedure that's widely used in the sector of Computer Numerical Control (CNC) machining. This process involves forcefully propelling a stream of abrasive beads under high pressure…

- Revolutionizing CNC Machining with Bead Blasting(die casting Laurel)

Bead blasting, as a critical aspect of modern manufacturing methods, can boost the overall quality and functionality of various components. This technique has proven incredibly beneficial in Computer Numerical Control…

- Revolutionizing CNC Machining for Advanced Aerospace Materials

Introduction to CNC Machining and Aerospace Materials The advancement in technology has revolutionized the industrial production sector, with Computer Numerical Control (CNC) machining playing a significant role. Essentially, CNC machining…