Introduction to CNC Machining and the Importance of Material Selection

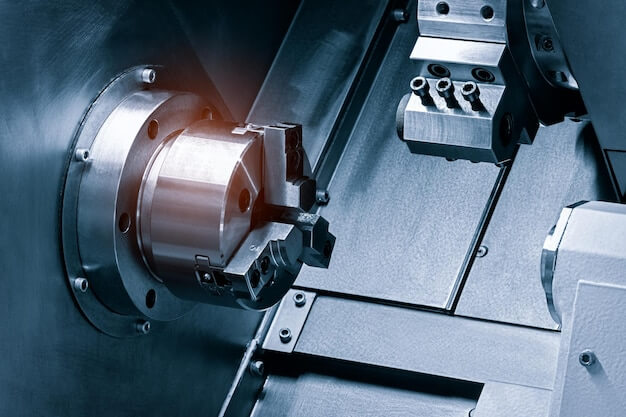

CNC machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technique can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

Selecting the correct material holds immense importance when it comes to CNC custom fabrication. While various materials such as steel, copper, or plastic can be utilized in this process, using aluminum stands out in particular due to its several advantageous properties. Some reasons that make aluminum an ideal choice for CNC machining include:

- Faster machining speeds: Due to softer and lighter characteristics, aluminum allows faster machining speeds which helps in increasing efficiency, thereby reducing manufacturing time.

- Ease of use: It’s easier to machine compared to steel thus needs lesser efforts or specialized equipment.

- Good thermal conductivity: Aluminum’s superior heat dissipation capability makes it suitable for applications requiring high levels of heat conduction.

Hence, the right selection of aluminum grade contributes significantly to achieving the desired machining results without compromising on quality and productivity.

Understanding Aluminum

Aluminum, a silvery-white metal with significant malleability and ductility, plays an integral role in manufacturing due to its unique characteristics. It is lightweight, corrosion-resistant, thermally conductive and non-magnetic which makes it favorable for various uses such as aircraft structures, automobile parts, window frames, kitchen utensils, and food packaging materials. In the realm of machining especially CNC custom fabrication, aluminum’s excellent machinability exemplifies itself in typical applications like prototyping components; thanks to its low melting point and high heat dissipation capacity, precise and intricate designs can be easily fabricated without damaging any machinery. Further, these physical properties allow manufactures to reduce energy consumption significantly thus making their production cost-effective.

- Definition and Characteristics of Aluminum: Lightweight yet strong, highly resistant to rust, thermal conductivity and non-magnetism property are some of the main traits that make aluminum ideal for various industrial applications.

- Variety of Uses in Manufacturing: Examples include but not limited to customization of auto-parts using CNC machinery because of its ability to withstand high temperatures, thereby ensuring precision cutting without compromising tool lifespan.

Advantages of Using Aluminum for CNC Machining

The use of aluminum in Computer Numerical Control (CNC) machining offers multiple advantages that prove immensely beneficial. Firstly, it’s important to note the basic benefits including its lightweight nature combined with impressive strength. This combination allows for ease during the machining process without compromising on the structural integrity of the finished product. It remains sturdy and durable despite weighing less than many other metals utilized in similar processes.

Next, we have aluminum’s corrosion-resistant properties which provide longevity to the machined parts. The natural oxide layer formed on aluminum acts as a barrier against rust, giving the products an edge over those made from metals prone to corrosion. Additionally, this property makes aluminum suitable for applications exposed to various environmental conditions.

- Lightweight yet strong: Aluminum pieces are easier to handle and install due to their low weight. Despite being lighter than many other materials, they demonstrate high durability and impact resistance.

- Corrosion resistant: A protective layer forms naturally on the surface of aluminum, making it resistant to corrosive elements such as water and air. This makes aluminum parts ideal for outdoor or heavy-duty applications where exposure to such elements is common.

- High-temperature tolerance: Further solidifying its utility in extensive range of applications, aluminum can withstand high temperatures. Its melting point is significantly higher than plastics and certain other metals, reducing risks associated with overheating.

In summary, these aforementioned qualities make aluminum an optimal choice when considering material selection for CNC machining projects.

Different Types of Aluminum used for CNC Machining:

- Aluminum Grades: Common aluminum grades used for CNC machining include 6061, 7075, and 2024, each offering specific properties suitable for different machining applications.

- Properties and Applications: Aluminum 6061 is known for its versatility and is widely used in various industries, while 7075 is valued for its high strength and is often utilized in aerospace and marine applications. On the other hand, 2024 is favored for its excellent machinability and is commonly used in structural components.

- Considerations: When selecting the best aluminum grade for CNC custom fabrication, factors such as strength, machinability, and specific application requirements should be carefully considered to ensure optimal results.

6061 Aluminum: The Preferred Choice for CNC Custom Fabrication

In the realm of CNC custom fabrication, 6061 aluminum stands out as an exceedingly versatile and highly machinable material. Its superior machinability makes it an ideal choice for intricate and complex machining operations. Furthermore, 6061 aluminum possesses excellent corrosion resistance properties that add to its appeal for uses in diverse manufacturing environments.

- Machinability: 6061 aluminum alloy can be easily cut, milled and shaped using standard machining methods. Thanks to its unique mechanical attributes, it maintains high precision tolerances during the machining process which is crucial for applications requiring extreme accuracy.

- Versatility: It can withstand a broad range of temperatures which opens up possibilities for its application across various industries from aerospace to architecture.

- Corrosion Resistance: Another benefit of 6061 aluminum is its exceptional resistance to rust and oxidation – a property notably significant when creating products meant for use under harsh environmental conditions.

A key illustration of where this type of aluminum flourishes is in producing automotive parts. High-precision car components such as engine blocks or gearboxes are often designed with extreme accuracies where the brilliant machinability of 6061 aluminum proves advantageous. In addition, due to its high strength-to-weight ratio, these parts remain lightweight yet robust leading to improved fuel economy – clearly demonstrating the product’s benefits over other materials.

Choosing the Right Aluminum Grade

When it comes to CNC custom fabrication, choosing the right grade of aluminum is paramount. Factors such as strength, corrosion resistance, and weldability should be major considerations based on the project requirements. For instance, if a project requires high-strength machined parts, Aluminium 7075 – known for its superior toughness – maybe your best bet.

On the other hand, Aluminium 6061 offers great weldability, making it ideal for projects that require extensive welding. Corrosion resistance is another essential factor when working in environments where the material could face exposure to elements that cause oxidation or deterioration. Here, aluminium grades like 5052 shine because their heightened alloy content gives them superior resistance to corrosive substances.

- Strength: Consider Aluminium 2024 or 7075 for applications requiring high fatigue resistance.

- Corrosion Resistance: Aluminium 5052 or 3003 are perfect for situations with exposure to corrosive elements.

- Weldability: Use versions like Aluminium 6061 or 6082 for flawless welding procedures.

In short, understanding these varying attributes will help you select the most suitable aluminium grade fulfilling not only the technical specification but also the cost-effectiveness of your machining project.

Pointers When Fabricating with Aluminum

Fabricating with aluminum necessitates precision and careful adherence to some vital do’s and don’ts. Using clean tools at all times is pivotal, as any dirt or particles can contaminate the material causing defects. Lubrication should be utilized liberally; a copious amount reduces friction which results in high-quality cuts. Furthermore, employing coolant mitigates heat problems.

Speed and feed rates must be aptly balanced for achieving precision, so recalibration should take place whenever necessary. In addition, it’s crucial to understand that not all grades of aluminum share similar characteristics— each have specific machining requirements. For instance, while series 6061 may be exceptionally versatile, other types like 2024 are more brittle and prone to cracking during fabrication hence assistance from professionals might be requisite.

Avoiding waste also forms an integral part of the process where possible utilization of computer-aided design (CAD) models could confirm precise measurements prior to actual fabrication. Finally, rehearsing on scrap metal before finalizing designs aids in refining skills and recognizing potential mistakes or issues ahead of time, minimizing waste or defects in your final product.

Conclusion

The utilization of aluminum in CNC custom fabrication distinctly marks it as an incredibly popular and versatile choice amongst all materials due to several compelling reasons. Such key considerations include its light weight combined with exceptional strength, excellent corrosion resistance, and superior conductivity capabilities which are fundamental for high-performance applications.

- This metal’s lightweight characteristic contributes significantly to the ease of machining without compromising on strength or durability.

- The remarkable resilience against rusting and general corrosion ensures prolonged product lifespan even against wear and tear or harsh environmental conditions.

- Furthermore, Aluminum’s conductivity capacity is one of the highest among metals which makes it ideal for electrical components and high heat transferring mechanisms.

In conclusion, these unique attributes make aluminum a superior option when selecting material for CNC custom fabrication projects; ensuring reliability, longevity, and optimum performance continuously.

Related Posts

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Breaking Barriers in CNC Machined Aerospace Structures

Introduction: CNC Machining in Aerospace Structures In the aerospace industry, accuracy, reliability and efficiency are paramount. To maintain these standards, modern day aerospace manufacturing heavily leans on Computer Numerical Control…