Introduction to Titanium Nitride Coating in CNC Machining

In the realm of CNC machining, efficiency and precision are paramount. However, the longevity of CNC tools is equally crucial, as frequent replacements lead to increased downtime and costs. One revolutionary solution to this challenge is the application of Titanium Nitride (TiN) coating. Renowned for its golden hue, TiN coating not only enhances the aesthetic appeal of the tools but significantly improves their performance and lifespan.

Understanding the Wear Mechanisms in CNC Tools

Tool wear in CNC machining is an unavoidable phenomenon, given the extreme conditions under which these tools operate. Several wear mechanisms play pivotal roles in the degradation of tool materials, primarily abrasive wear, adhesive wear, and chemical wear.

- Abrasive Wear: This occurs when hard particles or asperities from the workpiece material or the environment itself erode the tool surface. It’s akin to sandpaper effect, where the hard particles slide against the tool, gradually removing material and leading to tool dullness.

- Adhesive Wear: Often observed in metal cutting processes, adhesive wear arises from the welding of workpiece material onto the tool at high temperatures and pressures. These welded particles can break off, taking a portion of the tool material with them, and leading to the formation of built-up edges that can alter the tool geometry and degrade the surface finish of the workpiece.

- Chemical Wear: This involves the chemical interaction between the tool material and the workpiece or environmental elements, leading to the formation of wear-inducing compounds. For instance, in high-temperature environments, oxidation can lead to the formation of oxides on the tool surface, which can spall off and lead to tool wear.

- Diffusion Wear: At elevated temperatures, atoms from the tool material can diffuse into the workpiece and vice versa, leading to material loss and altered mechanical properties of the tool.

- Thermal Cracking and Plastic Deformation: Intense and fluctuating thermal loads can lead to the formation of cracks on the tool surface, while plastic deformation can occur at the tool’s cutting edge due to excessive heat and pressure, altering the tool geometry and reducing its cutting effectiveness.

Understanding these wear mechanisms is crucial for optimizing tool design and selecting appropriate coatings like TiN to mitigate wear and extend tool life.

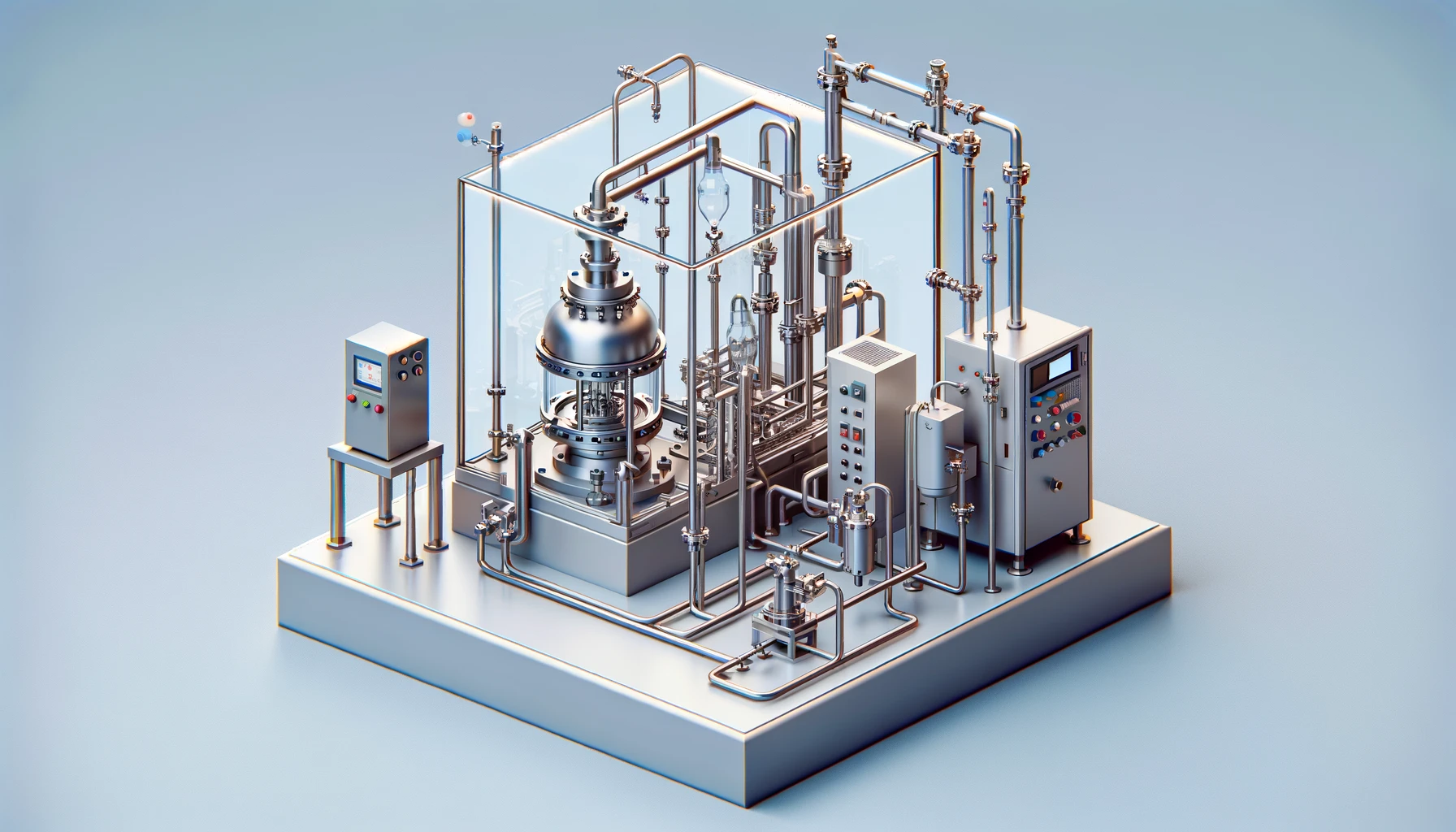

The Process of Applying Titanium Nitride Coating

The application of Titanium Nitride (TiN) coating on CNC machining tools is a sophisticated process that involves several critical steps to ensure optimal performance and adherence of the coating:

- Surface Preparation: The first step involves meticulous cleaning of the tool surfaces to remove any contaminants, oils, or residues. This is often achieved through a combination of chemical cleaning, ultrasonic baths, and fine abrasive blasting, creating a clean and slightly roughened surface that enhances coating adhesion.

- Pre-treatment: Following cleaning, a pre-treatment process such as ion etching may be employed to further purify and activate the tool surface. This step is crucial for removing any residual contaminants and creating a highly active surface for improved coating bond strength.

- Deposition Chamber Loading: The prepared tools are then placed in a vacuum deposition chamber. This chamber is designed to achieve high vacuum levels, essential for the purity and quality of the coating process.

- Base Vacuum Establishment: Before the coating process begins, a base vacuum is established within the chamber to eliminate air and any remaining contaminants. This ensures that the coating environment is as controlled and clean as possible.

- Plasma Creation: To deposit the TiN coating, a plasma is created within the chamber. This involves the introduction of a gas mixture, typically argon and nitrogen, which is ionized using high-energy electrical fields. The ionized gas forms a plasma that facilitates the deposition process.

- Titanium Evaporation: Titanium, the primary component of the TiN coating, is evaporated using either an electron beam or a resistive heating method. The evaporated titanium atoms then interact with the nitrogen ions in the plasma.

- TiN Layer Formation: As the titanium atoms collide with the nitrogen ions, they react to form Titanium Nitride, which then condenses on the surface of the tools. This process is carefully controlled to deposit a uniform and dense TiN layer, typically a few microns thick.

- Cooling and Post-Treatment: After the coating process is complete, the tools are cooled under controlled conditions to relieve any thermal stresses and ensure the coating’s integrity. A post-treatment process may also be applied to further enhance the coating’s properties, such as a final heat treatment to improve adhesion and hardness.

- Inspection and Quality Control: The final step involves a thorough inspection of the coated tools to ensure the coating meets the required specifications. Techniques such as scanning electron microscopy (SEM), X-ray diffraction (XRD), and hardness testing are used to evaluate the coating’s thickness, structure, and mechanical properties.

This intricate process ensures that TiN coated tools exhibit superior hardness, wear resistance, and reduced friction, significantly enhancing their performance and lifespan in CNC machining operations.

Comparative Analysis: Uncoated vs. Titanium Nitride Coated Tools

To illustrate the effectiveness of TiN coatings, consider the following data comparing the performance of uncoated and TiN-coated tools:

| Metric | Uncoated Tool | TiN-Coated Tool |

|---|---|---|

| Tool Life | 100 hours | 400 hours |

| Cutting Speed | 100 m/min | 150 m/min |

| Feed Rate | 0.1 mm/rev | 0.15 mm/rev |

| Surface Finish | 3.2 μm | 1.6 μm |

| Tool Wear Rate | 0.2 mm/100 hours | 0.05 mm/400 hours |

Case Study: Implementing TiN Coating in High-Volume CNC Operations

A notable example of TiN coating’s impact comes from a high-volume automotive parts manufacturer. After switching to TiN-coated drills for their engine block machining, they observed a 300% increase in tool life and a 20% increase in machining speed, significantly reducing downtime and increasing production throughput.

Optimizing CNC Parameters for TiN Coated Tools

The optimization of CNC parameters is crucial for maximizing the performance of TiN coated tools. Parameters such as cutting speed, feed rate, and depth of cut must be carefully adjusted to leverage the enhanced properties of TiN coated tools.

- Cutting Speed: TiN coatings allow for higher cutting speeds due to their high temperature resistance and hardness. However, the optimal speed must be determined to avoid excessive heat build-up, which can degrade the coating and reduce tool life.

- Feed Rate: Increasing the feed rate can enhance productivity, but it also increases the load on the tool. An optimal feed rate for TiN coated tools balances productivity with the mechanical stress on the coating to prevent premature failure.

- Depth of Cut: The depth of cut influences the material removal rate and the heat generated during machining. TiN coated tools can handle higher depths of cut compared to uncoated tools, but this capability must be balanced with the machine’s power and the material’s machinability.

- Coolant Use: While TiN coatings are capable of operating at high temperatures, the use of coolants can further extend tool life by reducing thermal stresses and flushing away chips that could cause re-cutting and additional wear.

- Tool Geometry: The design of the tool, including angles and edge preparation, should be optimized for TiN coated tools to reduce wear mechanisms such as chipping and edge rounding.

Case Study: Precision Aerospace Components

An aerospace company specializing in precision components implemented TiN coated end mills for machining complex titanium parts. The adjustment of machining parameters led to a 40% reduction in machining time and a 50% increase in tool life, significantly reducing production costs and improving delivery times.

Long-Term Benefits and ROI of TiN Coated Tools in CNC Machining

The long-term benefits of using TiN coated tools include not only extended tool life and reduced replacement costs but also improved production efficiency and product quality. The ROI from investing in TiN coated tools can be substantial, with break-even points often reached within a few months of implementation, depending on the volume and nature of CNC operations.

Data Table: ROI Analysis of TiN Coated Tools

| Parameter | Value Before TiN Coating | Value After TiN Coating | Improvement |

|---|---|---|---|

| Tool Life | 100 hours | 400 hours | 300% |

| Production Downtime | 10% | 5% | 50% reduction |

| Tool Replacement Cost | $10,000/month | $2,500/month | 75% reduction |

| Product Reject Rate | 5% | 2% | 60% reduction |

Challenges and Solutions in Maintaining Coated Tools

Maintaining TiN coated tools presents unique challenges, but with proper strategies, these tools can deliver extended service life and superior performance.

- Coating Adhesion: Ensuring the TiN coating adheres well to the tool substrate is crucial. Poor adhesion can lead to coating delamination. Solutions include proper surface preparation before coating and selecting an appropriate coating thickness.

- Wear Monitoring: Regular inspection and wear monitoring are essential to prevent catastrophic tool failures. Advanced techniques like laser scanning and digital microscopy can provide early detection of wear patterns.

- Re-coating: Once the TiN coating wears out, tools can often be re-coated. The re-coating process involves stripping the old coating, re-preparing the surface, and applying a new TiN layer, essentially restoring the tool to its optimal condition.

- Handling and Storage: Proper handling and storage are vital to prevent damage to the coating. Tools should be stored in protective sleeves or containers and handled with care to avoid impacts and abrasions that could compromise the coating.

Case Study: High-Precision Mold Making

A mold-making company faced challenges with TiN coated tools wearing out faster than expected due to complex geometries and high-hardness materials. By implementing a scheduled maintenance program and real-time monitoring of tool wear, they managed to extend the tool life by 20% and reduce unexpected downtime, enhancing overall productivity.

Related Posts

- PEEK vs. PEI in CNC Machining: Which Offers Better Performance for Engineering Applications?

Introduction to CNC Machining and the Materials PEEK and PEI CNC machining is an automated manufacturing technology that involves computer controls directing machinery in performing material cutting operations to produce…

- Optimizing Tool Paths: Advanced Techniques for Efficient CNC Titanium Machining in China

Introduction to CNC Titanium Machining in China In the dynamic landscape of global manufacturing, China stands out, especially in CNC (Computer Numerical Control) machining. Titanium, prized for its strength and…

- Exploring Bead Blasting in CNC Machining(titanium nitride coating Myrna)

CNC (Computer Numerical Control) machining has been a cornerstone of manufacturing processes for decades. It's an effective method for creating intricate and precise components from various materials - but once…