Introduction to Bead Blasting in Precision Machining

Bead blasting is an abrasive finishing process utilized in precision machining to clean or modify the surface finish of a workpiece. This technique involves propelling a stream of bead-shaped abrasive material, such as glass or ceramic beads, against the piece’s surface under high pressure. The primary role of bead blasting within the machining sector is to remove surface imperfections, create uniformity, and prepare parts for further processing or coating. Employing a bead blaster offers several benefits, including the achievement of a smooth, matte surface that enhances the adhesion of paints and coatings, reduces the likelihood of corrosion by removing contaminants, and can increase fatigue resistance by inducing residual compressive stresses on component surfaces. Using simple language and avoiding complex sentence structures ensures clear understanding about how bead blasting fits into the larger context of precision machining.

Materials and Selection for Blasting Beads in Precision Machining

In the realm of precision machining, a variety of materials are employed as blasting beads to refine and finish metal surfaces. Commonly used media include glass and ceramic beads due to their propensity to deliver a smooth, uniform finish without imparting excessive material degradation. Glass beads are favored for their relative softness which minimizes substrate damage, while ceramic beads offer heightened durability and aggressiveness for tougher applications. The selection criteria for appropriate blasting media hinge on factors such as the desired surface finish, hardness of the workpiece, and overall compatibility with the substrate. For instance, when dealing with softer metals like aluminum, glass beads might be chosen to prevent surface dimpling or warping, whereas the superior strength of ceramic beads would be harnessed for harder alloys that demand aggressive treatment without risk of premature bead shattering.

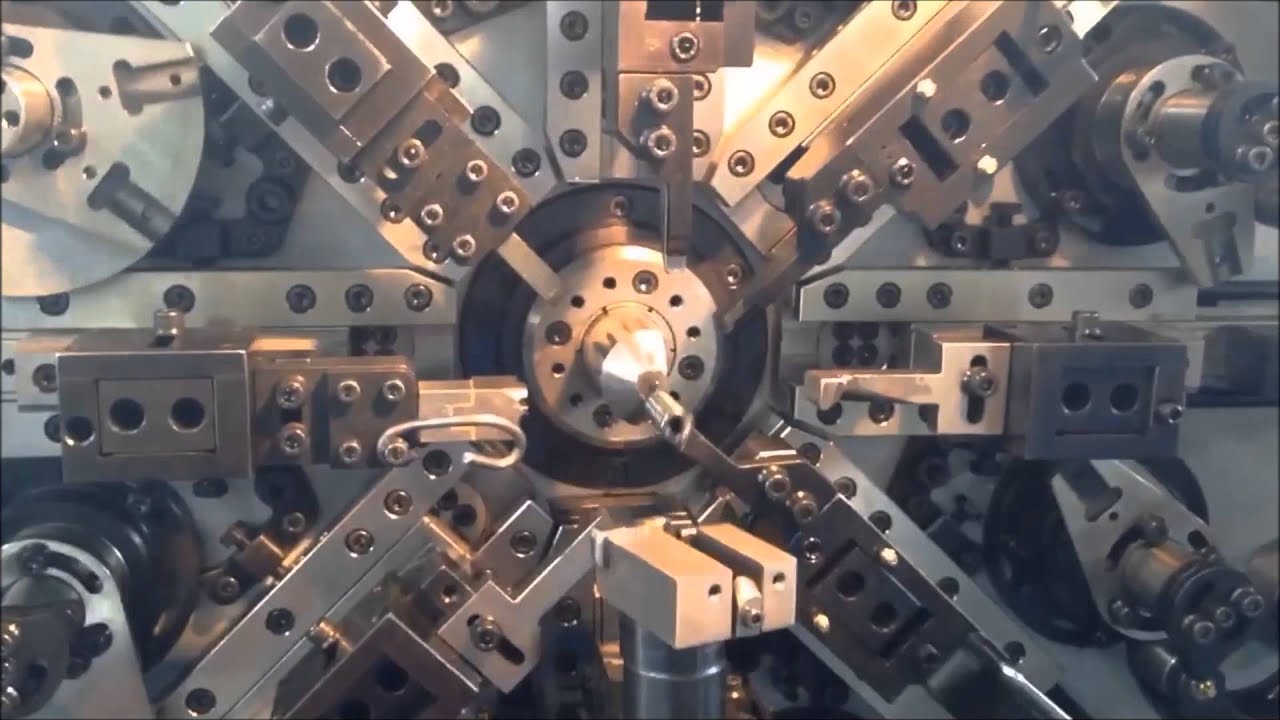

The Bead Blasting Process

Bead blasting is a finishing process utilized in precision machining where small glass, ceramic or metal beads are propelled at high velocity towards the surface of a workpiece to clean or modify its texture. The procedure commences with the placement of the component inside a bead blasting cabinet, which serves to contain the media and recycle it for repeated use. Once activated, the machine forcefully propels beads through a nozzle directed by an operator or automated system uniformly across the workpiece’s surface. This erodes any unwanted material, smoothing out surface imperfections or creating a uniform matte finish. Incorporating bead blasting into machining workflows can significantly enhance the final product’s quality by ensuring surfaces are free from burrs, scale, or other residues that could impair subsequent manufacturing stages such as coating or fitting. The compatibility of this method with delicate and complex geometries makes it a versatile tool within the precision engineering sector.

Advantages of Bead Blasting in Machining

Bead blasting offers notable enhancements to the precision machining process. By propelling fine beads at a surface, it uniformly smoothens and cleans even intricate geometries without altering critical dimensions, achieving an unparalleled level of detail. This results in a superior surface finish quality that can minimize imperfections and provide an optimal base for subsequent coatings or treatments. Moreover, bead blasting can gently remove residual material from cutting tools, potentially reducing wear and extending their lifespan. For example, machined components with complex contours subject to bead blasting exhibit improved fatigue resistance due to the removal of micro burrs and stress risers, ensuring prolonged operational durability.

Application Areas within Precision Machining

Bead blasting is extensively employed in precision machining, where it performs crucial surface finishing tasks that impact the functionality and longevity of components. For instance, in aerospace engineering, bead blasting is routinely used to finish turbine blades to ensure they possess adequate fatigue resistance and are free from any manufacturing remnants that might impede performance. Furthermore, a case study involving orthopedic medical implants illustrates bead blasting’s importance in creating finely textured surfaces that enhance bone integration and implant stability. Such examples underscore the necessity of bead blasting in applications demanding high levels of accuracy and reliability.

Safety Measures and Best Practices in Bead Blasting Operations

Ensuring safety during bead blasting operations is paramount. Operators must be equipped with the necessary safety gear, including protective eyewear, hearing protection, gloves, and dust masks or respirators to shield against airborne particles. The workspace should also be adequately ventilated. It’s crucial to adhere strictly to guidelines such as verifying that all equipment is in proper working condition before use, maintaining a clean environment to prevent slips and trips from scattered beads, and never bypassing machine guards or interlocks. Employees must be trained on emergency procedures, emphasizing the importance of shutting off equipment immediately if a malfunction occurs. To exemplify, when performing tasks requiring high precision, like surface finishing aerospace components, operators should ensure there is no room for error by meticulously following protocols designed for both operator safety and the attainment of desired machining toleracies.

Challenges and Limitations of Bead Blasting in Precision Machining

Integrating bead blasting into precision machining comes with its set of challenges. A primary difficulty is ensuring that the abrasive process does not compromise the dimensional integrity of the components, as even slight variations can be unacceptable in high-precision contexts. Furthermore, managing the consistency of the finish across different parts requires careful monitoring and adjustment of blasting parameters such as pressure, media size, and flow rate. To effectively tackle these obstacles, it’s crucial to establish stringent quality control procedures, utilizing precise measurement tools to monitor part dimensions before and after the bead blasting process. Additionally, selecting appropriate blasting media compatible with the material being machined mitigates potential contamination or damage to the workpiece. Thus, balancing the aggressiveness of bead blasting to achieve desired finishes without affecting structural characteristics demands specialized knowledge and attention to detail within the machining workflow.

Future Trends in Bead Blasting Technology

The relentless pursuit of enhancements in bead blasting technology is driven by current research focusing on optimizing surface finish quality and precision. Technological advancements are poised to enhance the control and repeatability of bead blasting processes, incorporating real-time monitoring systems that adjust parameters for consistent results even with complex geometries. Innovations such as smart abrasives embedded with sensors could revolutionize process feedback loops, leading to adaptive methods fine-tuned during operation. Predictions about the evolution of bead blasting suggest an increased integration with robotic automation, allowing for more precise manipulation and orientation of parts, as well as a move towards environmentally friendly media reclamation systems. Consequently, these advances will likely lead to reduced waste and lower costs, coupled with improved performance standards across a plethora of industries reliant on precision machining.

What is Bead Blasting and Its Significance in Precision Machining?

Bead blasting, a form of abrasive blasting, employs small spherical particles to clean or texturize the surface of precision machined components. It’s crucial for enhancing adhesion for coatings and for achieving desired surface roughness which are both essential aspects in high-tolerance applications. By projecting beads at high velocities towards the workpiece, imperfections are removed, resulting in an evenly mattified and contaminant-free surface that ensures better performance of the final product.

Different Materials Used as Beads and Selection Criteria

In bead blasting, various materials like glass, ceramic, steel, or acrylic are used as blasting media, each serving different purposes. Glass beads create smoother finishes, while ceramic beads provide more aggressive cleaning. Steel shots can peen surfaces enhancing their wear properties. The choice of material depends on the required finish, the hardness of the substrate, and whether any contamination from the blasting medium needs to be avoided. For instance, use non-ferrous beads like glass or ceramic when preventing ferrous contamination on stainless steel parts.

Enhancement of Component Longevity through Bead Blasting

Bead blasting can positively impact the lifespan of machined components by stress-relieving the surfaces and reducing crack initiation points. This process effectively eliminates microscopic fissures and machining marks, which could otherwise lead to premature part failure under cyclical loads. Also, it prepares the surface for further treatment processes, such as coating or painting, that protect against environmental aggressors, thus extending the operational life of the component.

Safety Measures during Bead Blasting Operations

While operating a bead blaster, safety is paramount. Protective equipment such as goggles, face shields, gloves, and appropriate clothing is mandatory to shield operators from airborne debris. Ensuring proper ventilation and dust extraction systems are in place mitigate the risk of inhaling fine particulates. Routine checks and maintenance on the bead blasting apparatus also reduce the possibility of malfunctions that could pose hazards during operation.

Limitations of Bead Blasting on Surfaces and Materials

Although versatile, bead blasting may not suit all surfaces and material types. Delicate or soft materials could deform or erode under the force of the beads. Similarly, intricate geometries can present a challenge as beads might not reach recessed areas, leading to inconsistent surface finishes. Therefore, assessing the compatibility of bead blasting with the intended material and design complexities beforehand is indispensable to ensure achievement of quality outcomes without causing detrimental effects to the workpiece.

Other Articles You Might Enjoy

- Precision CNC Machining for the Aerospace Defense Industry

Precision CNC Machining in the Aerospace Defense Industry In modern manufacturing sectors, precision Computer Numerical Control (CNC) machining plays a critical role. It is an automated process that uses pre-programmed…

- The Evolution of CNC Machining: From Aluminum to Composite Materials

Introduction to CNC Machining CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to initiate and manipulate machine tools, such as lathes, mills and grinders. With…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…