Introduction to Custom Parts Manufacturing and Materials: Brass vs. Copper

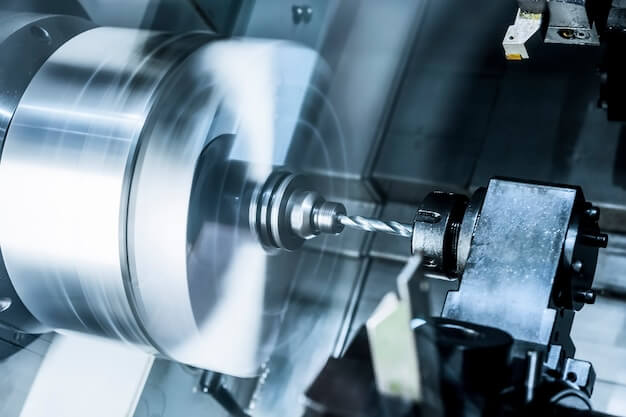

The process of custom parts manufacturing plays a vital role in diverse industries such as automotive, aerospace, medical, and more. It involves the creation of unique, tailor-made components, designed precisely to meet specific requirements or applications. An essential factor in this intricate process is the choice of material used, particularly brass and copper. They are notably significant due to their inherent properties.

- Brass, an alloy of copper and zinc, stands out for its strength, durability, corrosion resistance, and excellent heat conductivity.

- Copper, recognized for its electrical conductivity and malleability, makes it ideal for various applications.

In essence, understanding these materials’ benefits and limitations allows manufacturers to most effectively leverage them in creating high-performing, cost-efficient custom parts. For instance, while both materials offer superior conductive properties, if a design requires maximum electrical conductivity, copper would likely be the preferred choice over brass.

Understanding Brass

Brass is a versatile metal alloy primarily made up of copper and zinc. The proportion of each constituent can be varied to create brasses with distinctive colors and characteristics suitable for different applications. Ideally, brass displays excellent machinability, good strength, outstanding corrosion resistance, and has an eye-catching golden appearance.

In custom parts manufacturing, the use of brass is noted in numerous key areas due to its unique properties. For instance:

- Machinery Parts: Its superior machinability and anti-frictional properties make brass an optimal choice for producing gears, bearings, and other machine components.

- Electrical Connectors: Due to its excellent conductivity, brass is often used to fabricate high-quality electrical connectors and terminals.

.

Taking these attributes into account, it’s clear how instrumental brass is in providing flexibility and durability in customized part production.

Understanding Copper

Copper is a soft, malleable, and ductile metal known for its exceptional electrical conductivity and thermal resistance properties. A distinguished characteristic of copper that makes it valuable in custom parts manufacturing industry is its highly resistant nature to corrosion in most environments due to the formation of stable oxide films. This property expands its longevity and durability in critical applications.

In the realm of custom parts industry, copper exhibits diverse significant uses. It plays an integral role as a key element in crafting precision components such as :

- Electrical connectors: Given its high electrical conductivity, copper is typically utilized in manufacturing dependable, efficient electrical and electronic connectors, optimizing energy transfers.

- Radiator cores, tubes, tanks: With an unmatched thermal resistance, copper finds extensive use in enhancing robustness and heat dissipation efficiency in these cooling system elements.

- Bearing surfaces: Copper’s excellent wear resistance makes it ideal as bearing sleeves or bushes, reducing friction within machines and ensuring smooth operations.

Therefore, considering these attributes and versatile applications, copper holds a substantial place in the field of custom parts manufacturing.

Advantages of Brass over Copper in Custom Parts Manufacturing

In the realm of custom parts manufacturing, choosing the right material is pivotal for the success of a project. While copper is renowned for its electrical conductivity and corrosion resistance, brass, an alloy of copper and zinc, presents a set of unique advantages that make it a preferred choice for certain applications. This section delves into the benefits of brass over copper, emphasizing its suitability for custom manufacturing projects.

Enhanced Machinability

One of the primary advantages of brass is its superior machinability. Compared to copper, brass offers easier cutting and shaping, which can significantly reduce manufacturing time and costs. This is particularly beneficial in rapid prototyping and custom parts manufacturing, where precision and efficiency are paramount.

Corrosion Resistance

- While both materials exhibit good corrosion resistance, certain grades of brass, especially those with high manganese content, offer improved resistance to corrosion. This makes brass an excellent choice for components exposed to corrosive environments.

Aesthetic Appeal

Brass boasts a unique subdued yellowish-gold color, which is often sought after for decorative and aesthetic applications. Its distinctive appearance can enhance the visual appeal of custom-manufactured parts, making it a popular choice for architectural, interior design, and musical instrument manufacturing.

Cost-Effectiveness

| Material | Cost Comparison |

|---|---|

| Copper | More expensive |

| Brass | Less expensive due to higher zinc content |

Brass’s composition, which includes a significant amount of zinc—a cheaper metal than copper—makes it a more cost-effective option for large-scale and budget-sensitive projects.

Anti-bacterial Properties

Brass also exhibits anti-bacterial properties, making it a suitable material for medical devices, sanitary applications, and any other application where hygiene is a critical concern.

In conclusion, while copper is unmatched in certain properties such as electrical conductivity, brass offers a combination of machinability, aesthetic appeal, cost-effectiveness, and enhanced corrosion resistance. These advantages make brass a versatile and practical choice for custom parts manufacturing, especially in applications where these specific attributes are prioritized.

Advantages of Brass Over Copper in Custom Parts Manufacturing

In the realm of custom parts manufacturing, brass holds significant advantages over copper. For starters, brass is more malleable and easier to shape, allowing for intricate designs without compromising strength or durability. Additionally, thanks to its higher melting point, brass can withstand more heat than copper, which makes it an ideal choice for components that operate under high-temperature conditions.

Brass also outshines copper when it comes to corrosion resistance. Even in harsh environmental conditions like extended exposure to saltwater, brass exhibits superior resistance to rusting than copper. This attribute greatly boosts accumulative lifespans of marine hardware or plumbing fittings manufactured using brass, resulting in enhanced operational efficiency and cost savings. To bolster this claim with a real-world instance, consider the case of musical instruments such as trumpets and saxophones. These are frequently crafted from brass instead of copper owing primarily to brass’s heightened resistance to wear and tear and ease of manipulation into desirable shapes.

Lastly, regarding aesthetic appeal, brass radiates a richer, gold-like glow compared to copper’s reddish-brown tint. This feature grants brass a distinctive edge in decorative applications where appearance holds equal, if not more, importance as functional efficacy.

Benefits of Copper Over Brass in Custom Parts Manufacturing

In the realm of custom parts manufacturing, copper comes with several unique benefits over brass that can make it more suitable for certain tasks. Firstly, copper boasts superior heat conductivity which enables rapid and efficient transfer of thermal energy. This feature is particularly advantageous in applications such as heatsinks and cooling systems.

- Electrical Conductivity: One real-life instance where copper outranks brass is in electrical components like wires and circuits. Copper’s exceptional electrical conductivity permits a smooth flow of electric current with minimal power loss, increasing the overall efficiency and effective life span of these pieces.

- Ductility and Malleability: Hellbent on making intricate shapes and designs? Copper’s ductile nature could cater to your needs much better than brass. Manufacturers often prefer copper due to its malleability when producing customized pieces demanding high precision and intricacy.

- Resistance to Corrosion: In marine environments or jobs related to water supply, copper is favoured over brass because of its superior resistance to corrosion, providing excellent durability and longevity under such conditions.

Thus, while both metals have their merits, copper excels in various specific areas offering compelling advantages to manufacturers across industries.

Decision Factors in Selecting Brass or Copper

The choice between brass and copper in custom parts manufacturing is mainly influenced by a few key factors including the intended application, budget constraints, durability requirements, and aesthetic preference. The specific usage of the component plays a crucial role; for instance, brass tends to be more suitable for applications that require resistance to corrosion such as plumbing fixtures while copper’s excellent thermal and electrical conductivity makes it ideal for electronics and wiring systems.

- Intended Application: Utilizing each material in their appropriate fields of use ensures optimal performance. E.g., brass for anti-corrosive properties and copper for electric circuits due to its superior conductivity.

- Budget Constraints: Copper can often carry a higher price tag than brass. Therefore, cost considerations can swing the decision towards using brass especially for large-scale production.

- Durability Requirements: While both materials exhibit good strength, copper’s greater malleability results in more robust components under high stress environments.

- Aesthetic Considerations: Some manufacturers may opt for brass due to its gold-like appearance which can add visual appeal to the finished product.

To make an informed selection between these two materials, having a clear understanding of their own technical specifications and how they align with the requirements of the project are essential. For example, if high thermal conductivity is a must-have feature, then despite the cost, copper would be the preferable choice.

Conclusion

In the comparative analysis of brass and copper in custom parts manufacturing, each material presents unique advantages depending on specific application needs. Brass boasts superior machinability, corrosion resistance, and suitability for high-temperature environments, making it a fitting choice for components such as valves, fittings, or mechanical gears. On the other hand, copper’s exceptional electrical conductivity characterises its relevance in sectors including electronics and telecommunications. It also promotes better thermal efficiency and is more pliable than brass, advantageous for intricate part fabrication.

Understanding these distinct material properties is critical in choosing the optimal metal for different production demands, potentially improving both product performance and cost efficiency. Comprehensive knowledge of material differences allows an informed selection tailored to the component’s functionality, lending to the overall quality and longevity of manufactured products.

FAQs: Addressing Likely User Pain-Points

One frequently asked question in the realm of custom parts manufacturing is whether opting for the more expensive material such as brass implies better quality over more affordable options like copper. This belief, however, isn’t always accurate. While it’s indisputable that brass generally costs more than copper, this doesn’t necessarily translate to superior quality.

- Brass often has a higher price due to its distinctive attributes such as strength and resistance to corrosion. That said, these characteristics may not be necessary for all applications.

- Copper, albeit cheaper, could offer better elemnts based on your specific needs. It provides excellent electrical conductivity and is easier to work with, making it ideal for certain components dependent on these features.

- The choice should fundamentally hinge on the part’s function and application rather than the cost factor alone.

In conclusion, while brass might seem like the premium choice because of its price tag, the ‘better’ material truly depends on the functionality required. Thus, don’t let the expense dictate the quality; instead, consider the technical needs of the project at hand.

Other Articles You Might Enjoy

- Brass vs. Copper in Custom Parts Manufacturing: A Comparative Analysis

Introduction to the Importance and Uses of Metals in Custom Parts Manufacturing In custom parts manufacturing, metals play a significant role due to their robustness, versatility, and adaptability. Frequent application…

- Ceramic vs. Metal Parts Manufacturing: Which is Best for Your Project?

Introduction to Ceramic and Metal Parts Manufacturing The manufacturing industry has a wide range of processes, among which the production of ceramic and metal parts remains crucial. These two material…

- Ceramic vs. Metal Parts Manufacturing: Which is Best for Your Project?

Introduction to Parts Manufacturing and Material Selection The parts manufacturing industry is a broad portfolio that entails the construction of diverse machinery elements used in various settings, ranging from automobiles…