What is G-Code?

G-code is a generic term for a programming language used to advise a numerically-controlled machine tool. It manages all elements of device activity, including spindle rate, the tool path, exactly how rapid to move, and where to locate itself in a multi-axis space.

Why is it Vital to Confirm the G-Code?

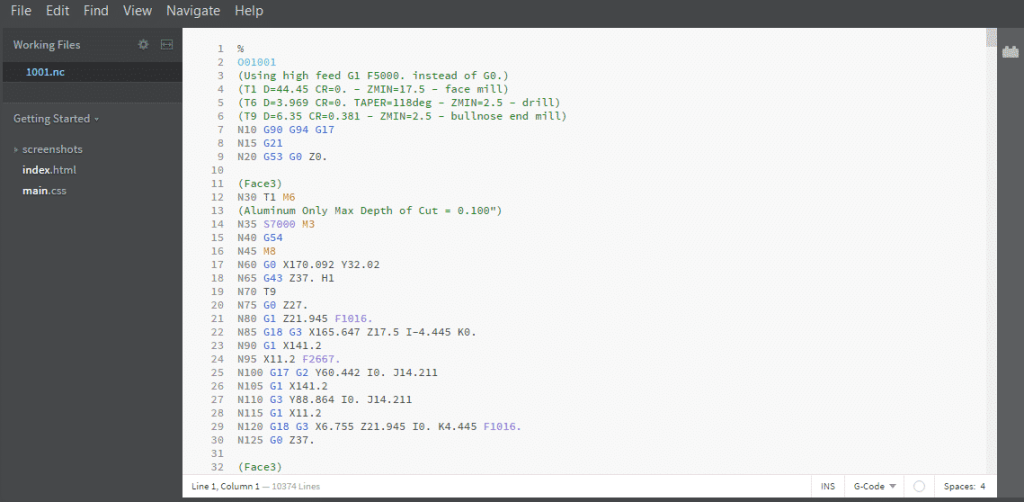

The complicated shapes used in CNC machining require thousands of lines of code to guide every motion the cutter head makes throughout the program. A single error in this code can result in a head crash, a broken cutter, wrong dimensions, junked components, bad surface area quality, and wasted time. This code must be correct in order to generate great components, make the best use of efficiency, protect against maker device damages and also safeguard worker security.

Where Does G-Code Come From?

It was initially developed in the 1950s at MIT in their Servomechanisms Research laboratory as part of the initial academic efforts to develop market standards for computer-controlled equipment tools

How is G-Code Generated?

Although some versions of the language exist, G-code is created when a three-dimensional CAD illustration is analyzed by the specialty programs used to control the CNC devices. In our instance, we use Delcam PowerMILL ® from Autodesk for all of our CNC milling as well as turning.

Are All G-Code Programs The Same?

No. There are many possible methods for a machine to make a custom part. The G-Code outputted by a given software program is simply one possible interpretation of the best-reducing program based upon many variables such as the type of the machine, component geometry, basic material, etc. The estimation can be a complex one, as well as is not always maximized for the actual circumstances on the factory floor.

How Do We Enhance the G-Code That We Use For Your Parts?

Once Delcam PowerMILL has created the G-Code for your part, we use a second program called Vericut from CGTech. Vericut is used to qualify every cutting program we make before it goes to the CNC machine. Vericut helps to determine the ideal tool speed and feed rates, the tool path, and more. Vericut maximizes efficiency, reduces waste, avoids tool crashes or broken cutters, and provides superior surface finish results.

The Bottom Line

When you use our CNC machining services, you may not see all of the work behind the scenes. We placed the additional effort right into ensuring that all of the information of your job has been called in for optimum efficiency, finest, and also least expensive expense.

Other Articles You Might Enjoy

- Understanding Bead Blasting in CNC Machining(cnc g code Jacqueline)

CNC (Computer Numerical Control) machining is a dominant method employed for multiple manufacturing systems across the globe. From healthcare to aerospace, this technology has revolutionized how we manufacture products. One…

- CNC Machining for the Renewable Energy Sector: Material Choices for Durability and Efficiency

Introduction to CNC Machining in the Renewable Energy Sector CNC (Computer Numerical Control) machining stands as a pivotal manufacturing process in the renewable energy sector, enabling the precise production of…

- High Volume CNC Machining in Copper: Efficiency at Scale

Introduction to High Volume CNC Machining in Copper CNC (Computer Numerical Control) machining is a subtractive manufacturing process involving pre-programmed computer software dictating the movement of factory tools and machinery.…