Insert molding is a manufacturing technique where components, often metal parts, are placed into a mold and encapsulated by molten plastic to create a final composite piece with enhanced functionality. This process differs markedly from traditional injection molding, where preformed parts are not typically incorporated into the molded article. The benefits of insert molding include improved part strength, reduction in assembly and labor costs, and the ability to combine disparate materials into a single component for complex applications. A common application is seen in electronic devices, where metal inserts are molded within plastic casings to provide durable anchoring points or electrical connectivity.

Steps Involved in the Insert Molding Process

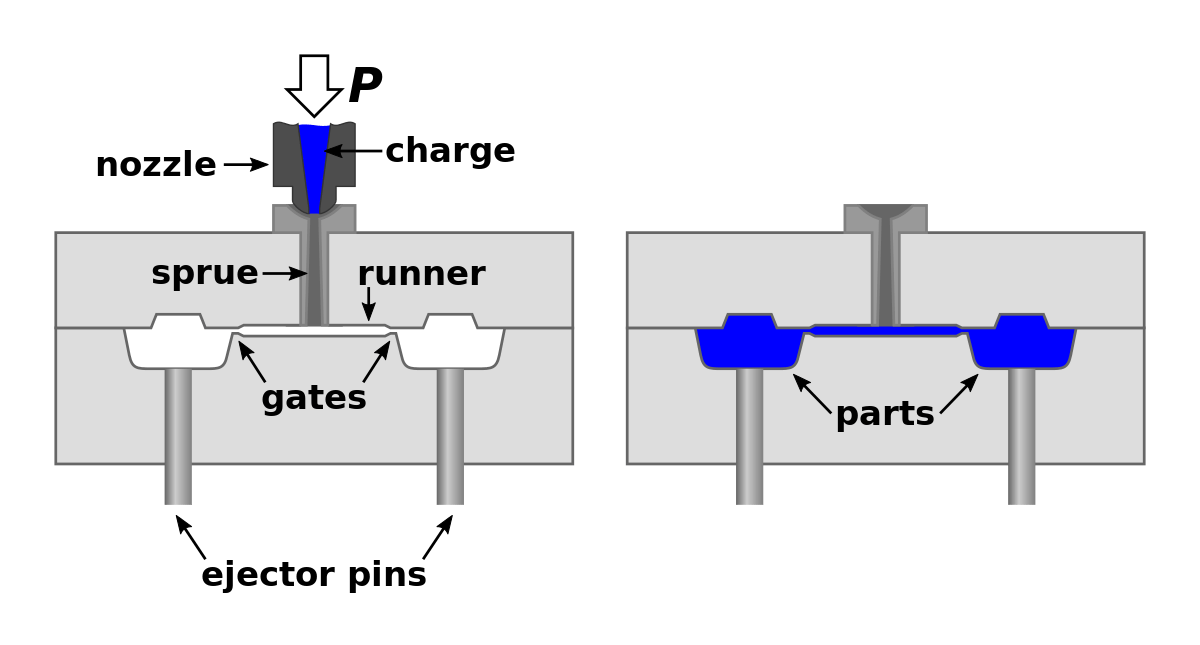

The insert molding process begins with the selection of substrates and inserts, which are typically made from metal or a different plastic that must adhere well when bonded with the injection material. Next comes the critical phase of designing the mold; this includes creating cavities within the mold where the inserts will be placed, ensuring precise fit and orientation for functionality. When it’s time for the mold cycle to commence, preformed inserts are accurately placed into these predefined cavities. Molten plastic is then injected surrounding the inserts entirely. As the heated plastic envelops the insert, it requires adequate cooling and solidification, thus enabling the two materials to fuse seamlessly. Finally, after solidification, the integrated part undergoes ejection from the mold and moves on to any necessary post-processing requirements, such as trimming or additional machining to meet final specifications.

Materials Used in Insert Molding

The efficacy of insert molding hinges upon the proper selection and integration of materials, where thermoplastics such as Nylon, Polypropylene, ABS, and Polycarbonate are frequently utilized for their resilience and adaptability. Deciding on the appropriate metal or non-metal inserts involves considering thermal resistance, electrical conductivity, and strength, with materials like brass, stainless steel, and aluminum often being selected for metals, while ceramics or plastics may be used for non-metals. Above all, material compatibility is paramount; the coefficient of thermal expansion for both the plastic and the insert must align to evade stresses that could lead to structural failures. For example, a polycarbonate housing may incorporate brass threaded inserts which expand at compatible rates under heat-sourced stress conditions during product operation.

Enhanced Part Strength and Integrity

Insert molding offers significant advantages in terms of part strength and integrity. By encapsulating an insert within the plastic during the injection process, a stronger bond is created as compared to joining separate pieces post-molding. This technique unites disparate materials into a singular composite piece with enhanced structural properties. Specifically, metal inserts can imbue plastic components with added durability and stability, enabling these composites to withstand mechanical stresses and thermal variations that might compromise purely plastic parts.

Improved Design Flexibility and Functionality

The versatility afforded by insert molding empowers designers with greater creative freedom. Various inserts can be molded directly into plastics, allowing for complex geometries and multifunctional parts without compromising design intent. This seamless integration not only expands the functional capabilities of the component but also opens up possibilities for miniaturization and intricate features, which would be impractical or impossible using traditional assembly methods.

Cost-effectiveness and Efficiency Gains

From a financial standpoint, insert molding demonstrates clear cost-effectiveness and efficiency gains. Merging multiple manufacturing steps into one reduces the need for secondary operations such as soldering or adhesive bonding, thereby lowering production time and expenses. Furthermore, the ability to integrate multiple functions into a single part minimizes material wastage and streamlines inventory management, contributing to overall operational savings.

Reduced Assembly and Labor Costs

A notable benefit of insert molding lies in its reduction of assembly and labor costs. Since inserts are encapsulated within the mold, there is less dependency on manual assembly processes, diminishing errors and inconsistencies associated with human intervention. The automation of this technique decreases the demand for skilled labor and accelerates mass production, leading to substantial reductions in both time-to-market and cost per unit—a boon for manufacturers aiming to optimize their bottom line.

Limitations and Challenges of Insert Molding

In insert molding, the complexity of mold design presents a significant challenge. Each mold must be precisely engineered to accommodate the embedded parts, accounting for their shape, size, and positioning. Failure in accurate mold design can result in compromised product integrity and function. Material compatibility issues are another hurdle; the chosen materials for both the insert and the thermoplastic matrix must adhere well together and withstand the processing conditions. Incompatible materials can lead to weak bonds or thermal damage to the inserts. Additionally, there is a risk of defects arising from improper insert placement. If an insert shifts or tilts during the molding process, it may cause incomplete filling around the insert, resulting in structural weaknesses or functional flaws in the final product. For example, an incorrectly placed threaded brass insert might compromise the assembly of an electronic device housing, thereby affecting its overall durability and reliability.

Industry Applications of Insert Molding

In the realms of electronics and automotive production, insert molding has become an invaluable technique for assembling complex components with precision. This process enables manufacturers to encapsulate electronic connectors or metal parts directly into thermoplastic material, thus improving product reliability by preventing part loosening and reducing assembly steps. In medical device manufacturing, sterilization requirements and biocompatibility mean that integrated parts must be created in a way that eliminates crevices where bacteria could grow, which is achievable through insert molding. A particularly compelling application can be found in aerospace connector manufacturing, where durability and resistance to extreme conditions are paramount. Connectors produced via insert molding benefit from increased structural integrity, ensuring stable electrical connectivity even in harsh environments.

Future Developments in Insert Molding Technology

The continuous evolution of insert molding technology is heralded by innovations that promise to enhance both the efficiency and sustainability of production processes. In terms of materials, we are seeing a progressive shift towards composites and advanced polymers designed for enhanced performance attributes such as heat resistance and durability while being more environmentally friendly. Techniques are also advancing with the integration of robotics and automation fostering increased precision and reducing human error. These adaptations lead to leaner manufacturing cycles and lower material wastage, aligning closely with the industry’s drive towards environmental sustainability. Moreover, growing trends include the adoption of smart sensors within molds to monitor conditions in real time, aiding predictive maintenance and ensuring optimal operation parameters—further stabilizing insert molding as a key player in future manufacturing landscapes.

Q&A Section: Understanding Insert Molding

A. Difference Between Insert Molding and Overmolding: Insert molding and overmolding are both manufacturing processes that combine different materials, but they have a distinct difference. Insert molding involves encapsulating a pre-existing part—often made of metal—with plastic during the injection molding process, while overmolding involves adding an additional layer of plastic onto an already molded plastic part to enhance features such as grip or aesthetics.

B. Material Constraints for Inserts in Insert Molding: Not every material is suitable for use as an insert in insert molding. The insert must be able to withstand the high temperatures and pressures of the injection molding process without degradation. Typically, metals and certain thermally stable plastics are used as inserts due to their resilience.

C. Contribution of Insert Molding to Product Durability: Insert molding enhances product durability by forming a strong bond between the insert and the molded material, which can result in improved structural integrity and increased resistance to wear and tear compared to assembled parts that might weaken or separate over time.

D. Size Limitations in Insert Molding: While insert molding allows for a great range of design flexibility, there are some size constraints. The process is typically more suited for small to medium-sized components, as the equipment used has limitations on how large of a mold it can accommodate, and larger inserts may affect the integrity of the plastic encasement.

E. Cost-Effectiveness of Insert Molding vs. Assembly: Insert molding can often prove more cost-effective than assembling discrete parts separately. This is because it reduces assembly time, eliminates the need for fasteners and adhesives, and can minimize the risk of failure at joint points, thereby reducing overall production costs and increasing production efficiency.

Related Posts

- Revolutionizing the Automotive Industry with CNC Machined Parts

Introduction: The Role of CNC Machined Parts in the Automotive Industry Technological innovation continues to revolutionize numerous industries, and the automotive sector is no exception. Among the game-changing technologies, Computer…

- The Future of Manufacturing: Exploring the Potential of Insert Molding in CNC Machining

As the manufacturing industry evolves, innovative techniques such as insert molding are reshaping the landscape of CNC machining. This article delves into the potential of insert molding in CNC machining…

- Low Volume Plastic Injection Molding: An In-Depth Guide

Low volume plastic injection molding is a manufacturing process used to produce small quantities of intricate plastic parts. This technique is essential in industries requiring unique, high-quality plastic components in…