Introduction: The Role of CNC Machined Parts in the Automotive Industry

Technological innovation continues to revolutionize numerous industries, and the automotive sector is no exception. Among the game-changing technologies, Computer Numerical Control (CNC) machining has become instrumental in transforming automobile manufacturing processes. CNC machined parts play a crucial role in the industry, offering extreme precision, consistency, and flexibility in producing various components.

- Precision: With CNC machines’ superior accuracy, manufacturers can produce car components with exact specifications, leading to better functioning and higher performing vehicles.

- Consistency: CNC machined parts ensure consistent component production, enhancing overall vehicle reliability. This capability is especially crucial for large scale manufacturing where maintaining high-quality standards across multiple units is vital.

- Flexibility: Offering incredible design versatility, CNC machining allows for an extensive variety of part shapes and sizes to be produced efficiently, allowing automakers to develop more innovative products to meet consumers’ evolving demands.

Basic Understanding of CNC Machined Parts

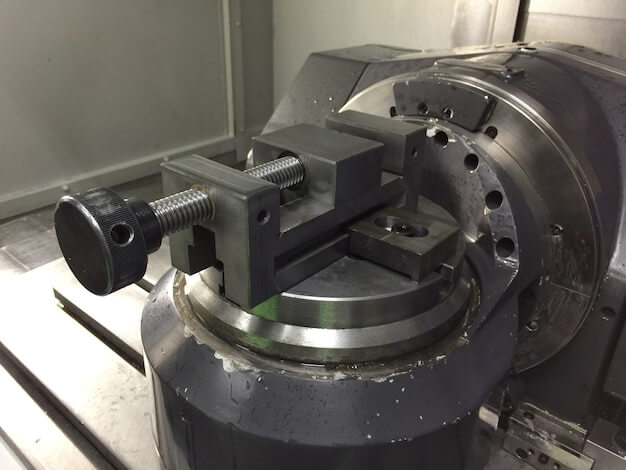

CNC machined parts are components meticulously carved or cut from a block of solid material such as metal or plastic, by a controlled Computer Numerical Control (CNC) system. This advanced method gives unparalleled accuracy in creating complex three-dimensional shapes that make up the essential elements of various automotive machines.

The process initiates with a digital 3D model blueprint of the part developed on a computer. This drawing is then converted into specific machine instructions or codes guiding the exact movements of the machining tools. The pre-programmed software and automated control enable minimized human error along with high repeatability and precision.

The sequential steps involved in this transformative technology include:

- Designing the CAD model for the required component

- Converting the design into CNC program which acts like instructions

- Setting up the machine and placing the work piece properly

- Starting the machine where cutting tools carve out the programmed shape resulting in precise output.

This process churns out intricately manufactured parts serving diverse purposes across the automobile industry and beyond, marking a revolutionary shift within manufacturing domains.

The Automotive Industry Before CNC Machining

Before the advent of Computer Numerical Control (CNC) machining, the automotive industry largely relied on traditional, manual methods of manufacturing car parts. These included processes like hand drafting and forging by blacksmiths. Though these techniques were viable at the time, they came with various limitations. Accuracy was often compromised as it was highly dependent on the craftsman’s skills, leading to inconsistencies between individual parts made. The lead-times were also prolonged due to the labor-intensive nature of these operations.

Let us consider a real-life example – the production of engine blocks. Prior to CNC machining, creating an engine block entailed casting molten metal into molds which then required further refining by milling and drilling. This process was not only time-consuming but lacked precision, especially for intricate designs and formations. Each part had to be manually worked upon, resulting in high wastage and inefficiencies as each piece differed slightly from the other due to human errors.

- Traditional Techniques: Included hand drafting, forgings by blacksmiths. It was labor-intensive and depended highly on craftsmen skills, thereby lacking consistency.

- Drawbacks: Compromised accuracy due to human errors, long lead times due to labor intensive work, unnecessary waste.

- Example: Engine block production using molds along with subsequent milling and drilling led to discrepancies in design due to lack of precision.

Revolutionizing the Automobile Industry with CNC Machining:

- Step 1: CNC machining has revolutionized the automotive industry by enabling the production of custom and precision parts for various automotive applications.

- Step 2: The use of CNC machining in the automotive industry allows for the production of components such as interior panels, starter motors, cylinder heads, drive axles, gearboxes, and custom parts with exceptional precision and efficiency.

- Step 3: CNC prototype machining is utilized to develop automotive prototypes to exact specifications, facilitating the creation of high-quality, functional automotive parts for testing and production.

- Step 4: Leveraging large CNC machining, the automotive industry manufactures parts for engines, shafts, and other vehicle components, contributing to the advancement and innovation in automotive manufacturing.

Benefits of CNC Machined Parts in Automobile Manufacturing

The incorporation of Computer Numerical Control (CNC) machined parts into the automotive industry production lines has brought about numerous benefits. Among these are increased precision, reduced waste, and improved productivity. The ability of CNC machines to produce components with remarkable accuracy enhances the quality of the final product significantly, ensuring every part fits perfectly and performs its function optimally. In turn, this greatly reduces the chances of factory returns due to defective parts.

CNC machining also lowers waste output, which plays an indispensable role in sustainable manufacturing. Through highly accurate cutting techniques, it minimizes raw material used – thus reducing cost and environmental impact. Furthermore, the high processing speed of CNC machines boosts production efficiency. Tasks that would normally take hours if done manually can be accomplished in mere minutes, resulting in faster delivery times and increased output.

A tangible example supporting these advantages is observed by analyzing a data-driven case study from one of the leading automobile companies. After implementing CNC machined component assembly lines, report shows a 30% reduction in production time, a decrease in material costs by 20%, and a dramatic fall in defect rates from 10% down to just 1%. Clear evidence of the quantifiable benefits derived from using CNC machined parts in vehicle assembly lines.

Future Outlook: How Will CNC Continue to Advance Auto Production?

The future of the automotive industry is intertwined with the advancement of Computer Numerical Control (CNC) machining. One potential use is in collaboration with burgeoning trends like 3D printing, creating a seamless integration between design and production processes. For instance, prototypes or intricate parts that were previously costly and time-consuming can be manufactured more efficiently via 3D model inputs into the CNC system.

- Innovations such as robotic arms controlled by CNC could streamline assembly lines further, increasing precision while reducing labor costs.

- Moreover, advancements in remote-control software offer potential for off-site CNC machine operation, elevating multitasking and productivity capabilities within the auto industry.

In conclusion, CNC machining has revolutionized the automotive industry by fostering innovation, efficiency, and precision. With continuous technological advancements pushing boundaries in automation and design principles, exciting prospects lying ahead promise vehicle longevity, reduced environmental impacts, and quicker manufacture turnaround times. Thus, CNC’s role in shaping auto-production’s sustainable and efficient future appears brightly imminent.

Other Articles You Might Enjoy

- Mastering Bead Blasting in CNC Machining(insert molding Edgar)

Bead blasting is a crucial process in the world of computer numerical control (CNC) machining. It’s an efficient procedure for using high-pressure air mixed with tiny glass beads to remove…

- Unlocking the Potential of Bead Blasting In CNC Machining(cnc machining tools Gerald)

Bead blasting is an integral process in Computer Numerical Control (CNC) machining, contributing to the finishing touches that enhance both aesthetic and functional aspects of manufactured parts. Whether you're a…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…