Introduction to Delrin

Delrin, also known as Polyoxymethylene (POM), is an engineering thermoplastic commonly used in precision parts that require high stiffness, low friction, and excellent dimensional stability. Recognized for its durability, it serves as a metal substitute due to these desirable attributes. Delrin is widely utilized in applications like gears, bushings, bearings, electrical insulating components, and many other mechanical devices where smooth operations are critical. Its unique balance of properties enables the material to perform consistently well in both domestic and industrial environments.

Mechanical Properties of Delrin

Delrin, a crystalline plastic known for its high tensile strength, exhibits mechanical properties that are ideal for parts requiring precision such as gears or bushings. Its inherent toughness and durability make it resistant to impact and wear, significantly outperforming other plastics like polyethylene in this regard. When compared with materials like nylon, Delrin maintains higher stiffness and dimensional stability at elevated temperatures which translates into better long-term fatigue endurance. In essence, the mechanical attributes of Delrin include remarkable resilience against repeated stresses, ensuring reliable performance even under challenging conditions.

Thermal Characteristics of Delrin

Delrin, a polyoxymethylene thermoplastic, exhibits excellent heat resistance and thermal stability, maintaining its properties across a broad temperature range. Its performance is characterized by a high melting point of approximately 175°C, which allows it to withstand elevated temperatures without significant deformation or loss of mechanical strength. However, continuous exposure to temperatures approaching this threshold can lead to a gradual reduction in material integrity. Furthermore, Delrin’s structural composition provides low thermal conductivity, enabling it to act as an insulator in applications requiring minimal heat transfer. Despite these resistant properties, when subjected to extreme cold, Delrin may become more brittle, impacting its toughness and potentially limiting its use in sub-zero environments.

Applications of Delrin in the Automotive Industry

Delrin, a durable acetal homopolymer, plays a vital role in the automotive industry due to its high tensile strength, stiffness, and enhanced dimensional stability. It is commonly used for manufacturing gears, bushings, and fuel system components which benefit from Delrin’s low wear and low friction properties. Additionally, its resistance to petroleum products makes it an ideal choice for parts like fuel sender units or door handle mechanisms where exposure to fuels and oils is inevitable.

Use Cases of Delrin in Consumer Electronics and Household Items

In the realm of consumer electronics and household items, Delrin is prized for its electrical insulating characteristics, mechanical precision, and durability. For example, it is often found in high-performance keyboard switches, offering a consistent tactile response while being resistant to frequent pressing actions. Moreover, its inherent toughness and moldability make it suitable for complex parts such as zippers and appliance housings, ensuring longevity and reliability even with daily use.

Advantages of Using Delrin Over Other Materials

In terms of cost-effectiveness and longevity, Delrin stands out as a superior choice over many traditional metals in engineering applications. Manufactured as a rigid thermoplastic, Delrin provides crucial economic advantages; its relatively low raw material cost and ease of machining frequently result in reduced production expenses when contrasted with metal fabrications. Moreover, the inherent stability and resistance to wear, moisture absorption, and chemicals contribute to less frequent maintenance needs and an extended service life. For instance, in applications involving moving parts such as gears, bearings, or bushings, Delrin’s self-lubricating properties reduce the necessity for additional lubrication, maintaining performance levels while minimizing upkeep costs.

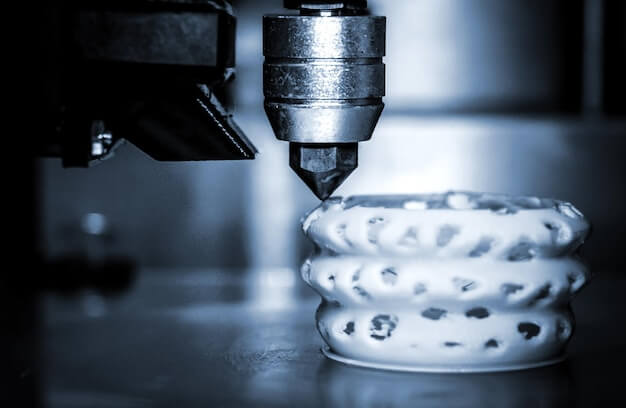

Machining and Fabrication of Delrin

Machining and fabricating Delrin requires specific techniques to ensure the integrity of the material is maintained. When cutting or shaping Delrin, sharp tools are imperative for a clean finish, as this engineering thermoplastic can easily deform under excessive heat from dull equipment. It’s possible to utilize various methods such as sawing, milling, drilling, and turning; all while maintaining moderate speeds and feeds to prevent overheating. For joining pieces of Delrin, mechanical fasteners or solvent bonding can be effective, given adhesive selection closely matches the material properties. During machining, intermittent checks with coolants help preserve dimensional stability and surface integrity. Importantly, dry machining may often suffice due to Delrin’s inherent lubricity. Practical tool geometry includes single-point tools at an acute angle for chip clearance, ensuring seamless operation without notching or gauging the substrate.

Environmental Resistance and Suitability of Delrin

Delrin is well-regarded for its high resistance to a wide variety of chemicals and solvents, including hydrocarbons, alcohols, and ethers. This makes it an excellent candidate for parts that require contact with automotive fuels, cleaning agents, or paint strippers without degrading. Its suitability extends to outdoor and marine environments where consistent exposure to the elements can be a concern. Resistances to moisture, UV light, and corrosion ensure Delrin maintains both its physical properties and appearance over time when used in outdoor gear components, boat fixtures, and other marine hardware. These traits make Delrin a versatile engineering material capable of enduring demanding environmental conditions.

Safety Considerations When Handling Delrin

During the processing of Delrin, a thermoplastic commonly used in precision parts, it is crucial to follow safety guidelines to prevent harm. Workers should ensure proper ventilation to avoid inhaling any potentially harmful fumes released during heating and molding phases. While machining Delrin, wearing protective eyewear and clothing is essential to guard against sharp shards or dust that might result from cutting or shaping. Additionally, equipment must be kept at optimal temperatures to avoid thermal degradation of the material, which can release formaldehyde gas. Regarding disposal, adherence to local regulations on recycling or discarding plastic waste minimizes environmental impact. It’s noteworthy that preheating Delrin before machining may reduce the risk of generating hazardous particles.

Other Articles You Might Enjoy

- Material properties of delrin

Introduction to Delrin Delrin, a trademark of DuPont, is a crystalline plastic known for its high tensile strength, stiffness, and enhanced dimensional stability. A type of acetal resin or polyoxymethylene…

- Know Your Materials: Delrin

Introduction to Delrin Delrin, Polyoxymethylene (POM), known for its high tensile strength and durability, stands out in the realm of thermoplastics. Its molecular structure showcases a series of -CH2O- units,…

- Delrin in CNC machining technology

Delrin, a trademarked name for polyoxymethylene (POM), is an engineering thermoplastic known for its high strength, rigidity, and resistance to friction and wear. This semi-crystalline plastic boasts exceptional dimensional stability…