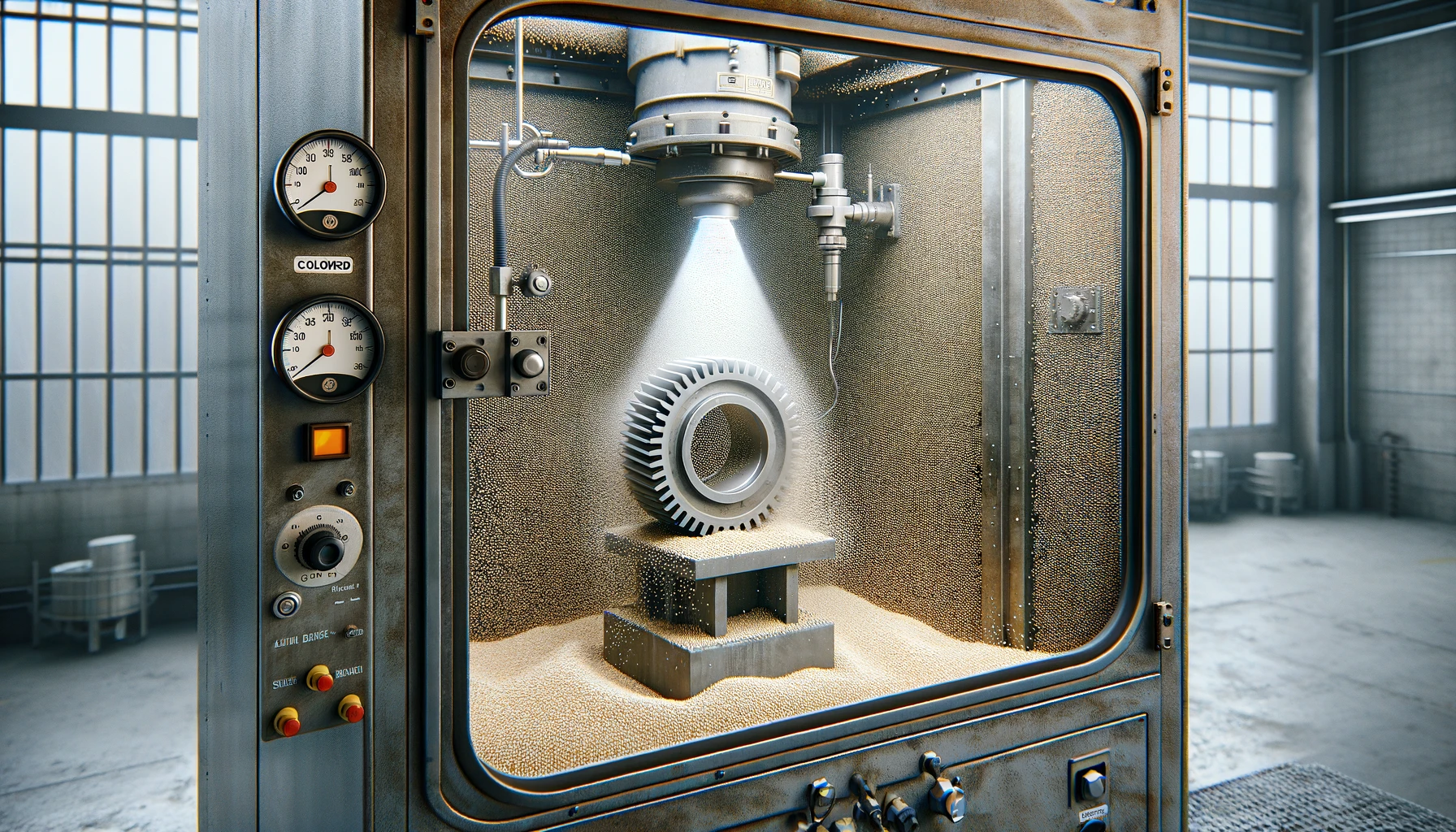

In the manufacturing industry, precision is paramount, especially when it comes to crafting critical components like bearing shafts. Among various machining techniques, CNC (Computer Numerical Control) machining stands out for its ability to deliver superior quality, accuracy, and efficiency in producing bearing shafts. This article explores the reasons why CNC machining is the preferred choice for crafting bearing shafts.

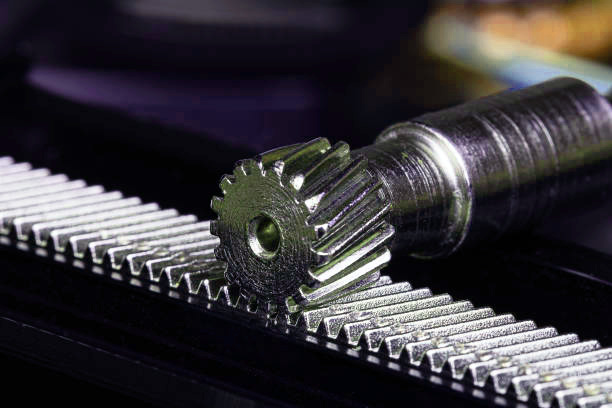

Precision Engineering: Ensuring Accuracy in Bearing Shaft Production

- CNC machining offers unparalleled precision, ensuring that bearing shafts meet tight tolerances and dimensional specifications consistently.

- Computer-controlled operations eliminate human error, resulting in precise and accurate bearing shafts essential for smooth mechanical operation.

Advantages of CNC Machined Bearing Shafts:

- Superior Surface Finish: CNC machining delivers smooth surface finishes, reducing friction and wear on bearing components.

- Complex Geometries: CNC machines can produce intricate bearing shaft designs with ease, allowing for complex features like splines, threads, and grooves.

- Consistency: CNC machining ensures consistent quality across large production runs, maintaining uniformity in bearing shaft dimensions and performance.

Materials Used in CNC Machining Bearing Shafts:

| Material | Properties | Applications |

|---|---|---|

| Stainless Steel | Corrosion resistance, high strength | Automotive, aerospace |

| Aluminum Alloy | Lightweight, good thermal conductivity | Automotive, electronics |

| Titanium | High strength-to-weight ratio | Aerospace, medical devices |

| Brass | Excellent machinability, conductivity | Electrical, plumbing |

| Carbon Steel | High tensile strength, affordability | Industrial machinery |

Efficiency and Productivity: Streamlining Bearing Shaft Manufacturing

- Faster Production: CNC machining accelerates the manufacturing process, reducing lead times for bearing shaft production.

- Reduced Waste: CNC machining minimizes material waste through optimized toolpaths and cutting strategies, enhancing efficiency and cost-effectiveness.

Customization and Flexibility: Tailoring Bearing Shafts to Specific Requirements

- Design Flexibility: CNC machining allows for easy modification of bearing shaft designs to meet custom specifications or accommodate unique application needs.

- Prototyping: CNC machining facilitates rapid prototyping of bearing shafts, enabling iterative design improvements and quick validation of concepts.

Conclusion:

CNC machining offers unmatched precision, efficiency, and flexibility in crafting bearing shafts, making it the preferred choice for manufacturers seeking high-quality components. By leveraging CNC technology, companies can achieve precise dimensions, intricate designs, and consistent quality in bearing shaft production, ultimately enhancing the performance and reliability of mechanical systems.

Other Articles You Might Enjoy

- CNC Precision in Crafting Bearing Shafts

Bearing shafts play a critical role in various mechanical systems, providing support and enabling smooth rotational movement. The precision required in crafting these components is paramount to ensure optimal performance…

- What are the requirements for CNC machining of bearing parts?

Bearings are common and important parts in the automotive industry, which can support transmission components and transmit torque. Generally, CNC machining centers are used to process bearing parts. So what…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…