Prototyping projects are instrumental in creating and modeling physical forms to test alternative approaches and validate designs. Want.Net, a leading provider in the industry, offers three key solutions that effectively guide prototyping projects from conception to realization.

What is a Prototype Project?

A prototype project follows a systems development method known as the prototyping model. It involves building, testing, and refining prototypes until an acceptable version is achieved. This iterative process ensures the development of a complete system or product. While prototyping techniques can vary in terms of materials, scales, and technology applications, evolutionary prototyping is particularly beneficial for bringing new products to life.

Three Key Steps to Navigate Prototyping Projects

Step 1: Rapid Prototyping

At the initial stage of prototyping projects, Want.Net leverages the power of rapid prototyping through 3D printing. This approach offers a quick, easy, and cost-effective way to transform design ideas into tangible objects. Using 3D printing, designers can create prototype models that closely resemble the intended product. These models serve as visual representations and are highly useful for presentations to focus groups, enabling designers to enhance the persuasiveness of their designs.

When opting for 3D printing, developers benefit from:

- A low-cost plastic prototype model

- The ability to produce parts with complex geometries

- A fast turnaround time of 2-5 days

- Access to specialty materials

Step 2: CNC Machining

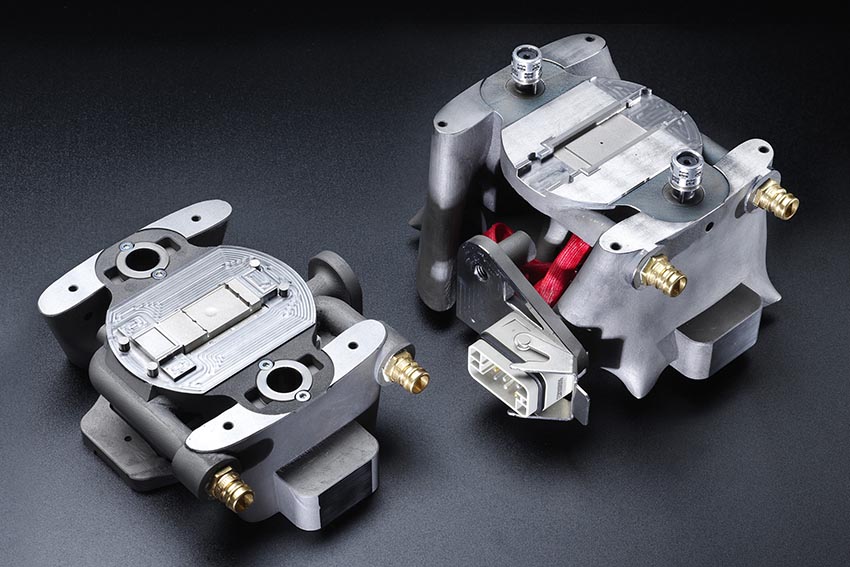

For developers seeking high-accuracy parts with excellent physical properties, CNC machining is the ideal solution. Want.Net boasts two decades of experience in CNC prototyping services and is equipped with both 3-axis and 5-axis capabilities. This advanced machining technique allows for the creation of prototype models that not only showcase aesthetics but also undergo comprehensive functional testing.

CNC machining is particularly suitable for parts with relatively simple geometries that can be manufactured through a subtractive process, especially when working with metal materials. Compared to 3D printing, CNC machining offers superior dimensional accuracy and produces parts with enhanced mechanical properties. With a typical turnaround time of within 2 weeks, Want.Net ensures prompt results while maintaining quality and precision.

Step 3: Rapid Tooling

Want.Net offers rapid tooling as a vital step bridging the gap between prototyping and production. This approach, often employed before the final production run using injection molding, proves highly valuable in optimizing costs and timelines. Rapid tooling involves the use of aluminum or soft steel, a stocked mold base, and hand-loaded inserts.

Rapid tooling is particularly beneficial in situations where traditional injection molding is either prohibitively expensive or unnecessary for the required part or volume. It presents a cost-effective solution for small-batch market testing or when large volumes are not anticipated in the future. Want.Net provides two injection molding service options for rapid tooling: one suited for smaller part quantities typically associated with prototyping and another tailored for larger part quantities common in low-volume production.

It is important to note that while 3D printing prototypes offer numerous advantages, they also have limitations such as limited material options, lower strength, and reduced weather resistance compared to other manufacturing methods.

Additional Details and Advantages

In the context of an aluminum casing prototyping project, Want.Net excels in accurate CNC machining. This process results in aluminum parts that possess properties and accuracy comparable to the final version. Common metals like aluminum, steel, and brass can be efficiently machined using Want.Net’s CNC tools. Importantly, the difference between prototypes and final products is minimal for machined metal parts, ensuring a seamless transition from design to production.

In addition to CNC machining, Want.Net utilizes wire EDM (Electrical Discharge Machining) for specific features such as ribs and through holes. By combining3-axis or 5-axis CNC milling with auxiliary processes like EDM and wire EDM, Want.Net achieves precise and efficient CNC aluminum machining. This integrated approach ensures that typical aluminum surface finishing is achieved to meet the highest standards of quality and aesthetics.

Furthermore, Want.Net places great emphasis on providing comprehensive support throughout the prototyping process. Their team of experts collaborates closely with clients, offering guidance and expertise to optimize design concepts and streamline manufacturing processes. This close partnership ensures that prototyping projects progress smoothly, from initial ideas to the realization of high-quality prototypes.

In conclusion, Want.Net offers three essential solutions for manufacturing prototyping projects. Through rapid prototyping, CNC machining, and rapid tooling, they provide a comprehensive range of services to bring designs to life, validate concepts, and pave the way for successful product development. With their expertise, advanced technology, and commitment to quality, Want.Net is the go-to partner for prototyping projects, ensuring efficiency, accuracy, and cost-effectiveness throughout the manufacturing process.

Recommended Reads:

- Top 8 Features to Look for in CAM Software for CNC Machining

- How to Optimize Your CAD Models for CNC Machining

- The Top 3 CAD Software for CNC Machinists

- 8 Must-Know Features of CAD Software for CNC Machining

- CNC Plasma Cutters: 3 Hidden Secrets Only Experts Know

- What is a CNC Plasma Cutter?

Related Posts

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…

- CNC Machining for Medical Applications: Compliance and Material Selection?

Introduction to CNC Machining in Medical Applications CNC or Computer Numerical Control machining is a manufacturing process wherein pre-programmed computer software dictates the movement of factory tools and machinery. This…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…