I. Introduction: Why Sheet Metal Captivates Me

As an engineer who’s spent years designing and building everything from car bodies to skyscraper facades, I’ve come to see sheet metal as the unsung hero of modern industry. Whether it’s the sleek panels of a Tesla or the sturdy framework of a bridge, sheet metal is everywhere, quietly shaping our world. Yet, its brilliance often goes unnoticed. In this guide, I’m excited to share my deep dive into sheet metal—its materials, processes, applications, and future—hoping to inspire you, whether you’re an engineer, designer, or innovator, to unlock the potential of sheet metal in your projects. Let’s embark on this journey together.

II. What is Sheet Metal? My Take on the Basics

When I first encountered sheet metal, I was struck by its simplicity: it’s just metal rolled into thin, flat sheets. But don’t let that fool you—this material’s versatility is mind-blowing. Sheet metal is defined by its thickness: too thin, and it’s foil; thicker than 6 mm (about 0.25 inches), it’s plate. You’ll typically find sheet metal as flat sheets or coiled strips, ready to be transformed into anything from a car hood to a kitchen sink.

One thing I learned early on is the importance of thickness specifications. Globally, millimeters rule, but in the U.S., we often use gauge—a quirky system where a higher number means thinner sheet metal. Here’s a tip: gauge differs between ferrous (like steel) and non-ferrous (like aluminum) sheet metal, so double-check to avoid costly mix-ups in your designs.

Reflecting on history, I find it fascinating that sheet metal has been around for centuries, once painstakingly hammered by hand. By the 17th century, rolling mills took over, and the 19th century’s steel advancements made sheet metal a game-changer—affordable, durable, lightweight, and fire-resistant. It’s no wonder it’s a staple in my projects today.

Core Manufacturing Methods: Hot-Rolled vs. Cold-Rolled

In my experience, how sheet metal is made sets the stage for its performance. Steel sheet metal starts with either hot-rolling or cold-rolling, and I’ve seen how these processes shape the material’s character:

- Hot-Rolled Sheet Metal: Rolled at high temperatures, this sheet metal is thicker, with a rugged surface. I use it for structural parts where precision isn’t critical.

- Cold-Rolled Sheet Metal: Rolled at room temperature, it’s thinner (up to 3 mm), smoother, and more precise. It’s my go-to for intricate components like enclosures.

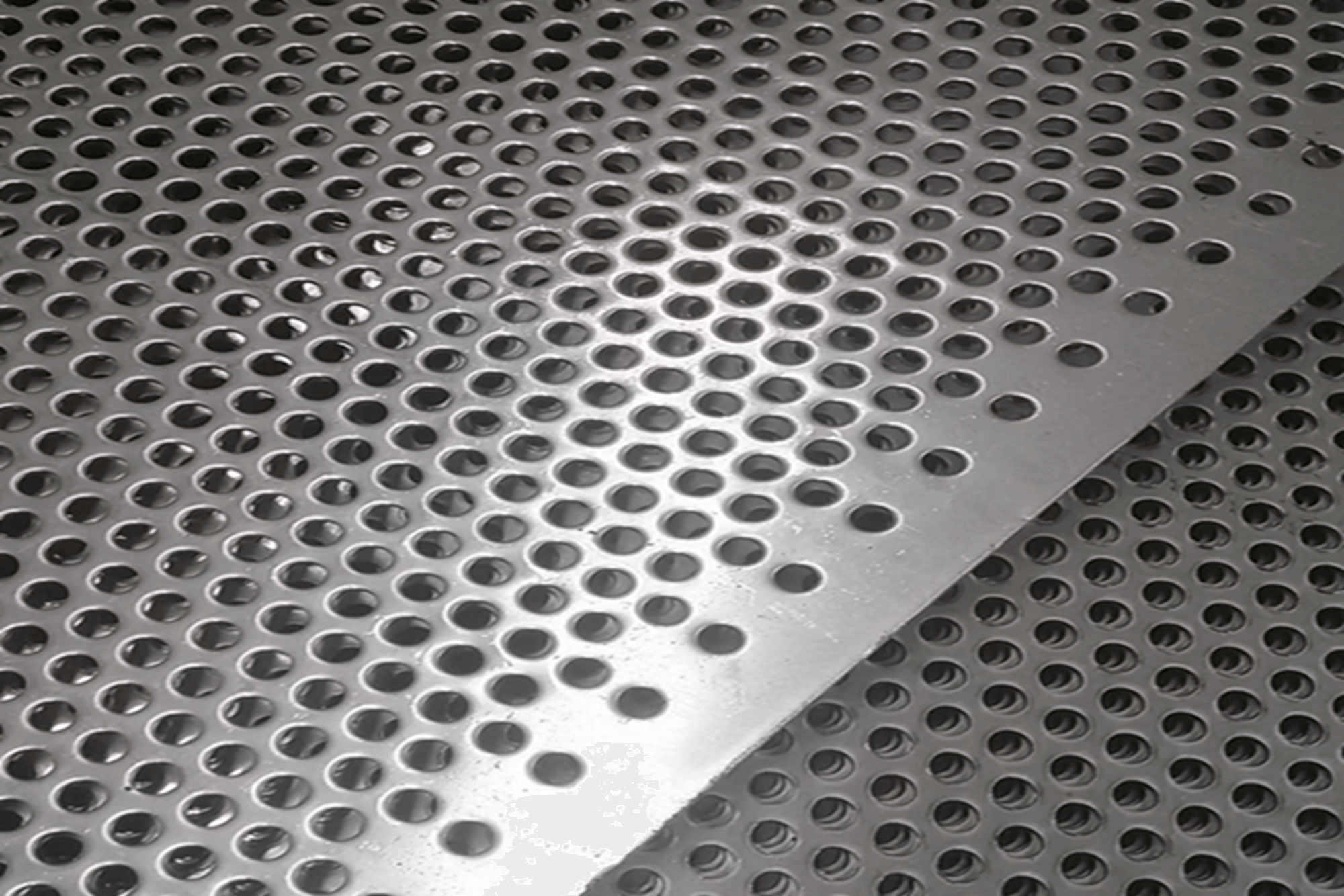

Specialty Sheet Metal Types

Over the years, I’ve worked with some unique sheet metal types: chequer plate for non-slip surfaces, corrugated sheet metal for added strength, blue sheet metal for corrosion resistance, and even tinplate for food cans. Each has its own charm, and choosing the right one feels like picking the perfect tool for the job.

III. A Comprehensive Guide to Sheet Metal Materials

Picking the right sheet metal material is one of the most critical decisions I make in a project. It’s a balancing act—tensile strength, weldability, corrosion resistance, weight, and cost all come into play. Let me walk you through the sheet metal materials I rely on and help you choose the best one for your needs.

In-Depth Material Analysis

Steel:

- Carbon Steel: My workhorse for sheet metal projects. It’s strong and budget-friendly but needs protection against rust.

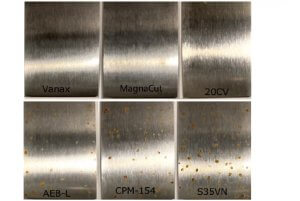

- Stainless Steel: With chromium for corrosion resistance, it’s my pick for food equipment or marine applications. Grades like 304 and 316 are my favorites.

- Alloy Steel: I turn to this sheet metal when I need specific properties, like extra hardness.

- Galvanized Steel: Zinc-coated for rust resistance, this sheet metal is easier to work with than stainless steel.

Aluminum: I love aluminum sheet metal for its lightweight magic. It resists corrosion, conducts heat and electricity, and has a stellar strength-to-weight ratio. Grades like 5052 for marine parts or 6061 for structural frames are my staples.

Copper & Brass:

- Copper: Its conductivity makes this sheet metal a must for electrical projects.

- Brass: A copper-zinc alloy, perfect for corrosion-resistant sheet metal in seawater.

Titanium & Specialty Alloys: When I’m working on aerospace or medical projects, titanium sheet metal is my go-to for its incredible strength-to-weight ratio. Gold or silver sheet metal? They’re rare but dazzling for niche applications.

Comparison Table of Common Sheet Metal Material Properties

Alt Text: Comparison table of sheet metal material properties, including low-carbon steel, stainless steel, aluminum alloys, copper, and titanium, detailing yield strength, tensile strength, density, applications, and cost.

| Material | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Density (g/cm³) | Key Features & Common Applications | Relative Cost Index |

| Low-Carbon Steel (A36) | 250 | 400–550 | 7.8 | Cost-effective, strong, rusts easily. Used for brackets. | $ |

| Stainless Steel (304) | 205 | 515 | 8.0 | Corrosion-resistant, hygienic. Used for kitchen utensils. | $$$ |

| Stainless Steel (316) | 205 | 515 | 8.0 | Chloride-resistant. Used in marine, medical applications. | $$$$ |

| Aluminum Alloy (5052-H32) | 193 | 228 | 2.68 | Marine-resistant, formable. Used for fuel tanks. | $$ |

| Aluminum Alloy (6061-T6) | 276 | 310 | 2.7 | Versatile, weldable. Used for aerospace, frames. | $$ |

| Copper (99.9%) | 70 | 220 | 8.92 | Conductive, ductile. Used for electrical components. | $$$$ |

| Titanium Alloy (Ti-6Al-4V) | 830 | 950 | 4.43 | High strength-to-weight. Used in aerospace, implants. | $$$$$ |

Note: Strength values vary by treatment. Cost index is relative.

IV. Sheet Metal Manufacturing Processes: My Step-by-Step Insights

Transforming raw sheet metal into a finished component is a journey I find endlessly fascinating. It’s a multi-stage process—design, cutting, forming, joining, finishing—and every step matters. Let me share how I navigate sheet metal manufacturing to create parts that shine.

Stages One & Two: Design and Cutting

I start with a CAD model, which I feed into CAM software to generate G-code for sheet metal cutting machines. Cutting is where sheet metal takes its first shape:

- Mechanical Cutting: I use shearing for straight cuts and punching for holes in sheet metal.

- Advanced Cutting:

- Laser Cutting: My go-to for precision (±0.05 mm) and complex sheet metal shapes.

- Plasma Cutting: Great for thick sheet metal, though less precise.

- Waterjet Cutting: Perfect for heat-sensitive sheet metal, no distortion.

Cutting Technology Comparison Table

Alt Text: Comparison table of sheet metal cutting technologies, including laser cutting, plasma cutting, waterjet cutting, and shearing, detailing principles, thickness, precision, edge quality, speed, and compatibility.

| Technology | Working Principle | Max Thickness | Precision/Tolerance | Edge Quality | Speed | Material Compatibility | Core Advantage | Core Limitation |

| Laser Cutting | Laser beam melts material | ~50 mm | Very High (±0.05 mm) | Smooth | Very Fast | Most metals | High precision | High cost |

| Plasma Cutting | Ionized gas melts material | ~50 mm | Medium | Rougher | Extremely Fast | Conductive metals | Cost-effective | Lower precision |

| Waterjet Cutting | Water erodes material | >300 mm | Very High | Smooth | Slower | All materials | No distortion | Slow, costly |

| Shearing | Blades cut material | Varies | Lower | Burrs | Extremely Fast | Most metals | Low cost | Straight cuts only |

Stage Three: Forming and Deformation

Forming sheet metal is where creativity meets precision:

- Bending: I use press brakes to shape sheet metal into V or U profiles.

- Stamping: Ideal for high-volume sheet metal parts.

- Roll Forming: I love this for long sheet metal strips with consistent cross-sections.

- Deep Drawing: Creates hollow sheet metal parts like cans.

Stage Four: Joining and Assembly

Joining sheet metal is an art:

- Welding: I choose MIG for speed, TIG for precision, or laser for intricate sheet metal.

- Fastening: Rivets or bolts for sheet metal assemblies.

- Bonding & Brazing: Adhesives or low-temperature fillers for sheet metal.

Stage Five: Finishing and Post-Processing

Finishing makes sheet metal shine:

- Surface Prep: I deburr or sandblast sheet metal for smoothness.

- Coatings: Powder coating or anodizing for sheet metal durability.

- Heat Treatments: Annealing softens sheet metal; quenching hardens it.

One lesson I’ve learned: early decisions, like choosing galvanized sheet metal but needing welding, can cause headaches. That’s why I swear by Design for Manufacturability (DFM) to keep sheet metal projects on track.

V. Cross-Industry Applications: Where Sheet Metal Makes a Difference

I’ve seen sheet metal shine across industries, and its versatility never ceases to amaze me. Whether you’re in automotive, aerospace, or electronics, sheet metal adapts to your needs. Let me share some stories of sheet metal in action.

Automotive Industry

In automotive, sheet metal is my foundation for body panels, frames, and exhausts. I focus on balancing safety, weight, and cost, using Advanced High-Strength Steel (AHSS) or aluminum sheet metal.

Case Studies: Tesla Model 3 & Cybertruck

- Model 3: I admire its mix of steel and aluminum sheet metal, optimizing safety and efficiency.

- Cybertruck: Its 3mm stainless steel sheet metal exoskeleton blew my mind—its hardness shaped the angular design, a bold sheet metal innovation.

Aerospace Industry

Aerospace demands sheet metal with extreme performance. I use aluminum-lithium alloys in projects like the Airbus A350, where sheet metal saves weight without sacrificing strength.

Architecture and Construction

I’ve specified sheet metal for roofing and cladding, loving its 40–70-year lifespan and aesthetic flexibility.

Electronics Industry

For enclosures and heat sinks, sheet metal—especially aluminum—offers EMI shielding and thermal efficiency. I once designed a sheet metal MacBook enclosure, marveling at its sleek precision.

VI. Design for Manufacturability (DFM): My Path to Success

DFM is my secret weapon for sheet metal projects. It’s about designing sheet metal parts that are easy to make and cost-effective. Let me share my DFM tips to help you nail your sheet metal designs.

DFM Core Principles

- Uniform Thickness: Sheet metal comes from one sheet, so keep thickness consistent.

- Standardization: Standard sheet metal sizes and fasteners save money.

- Simplification: Fewer sheet metal parts mean lower costs.

Key Bending and Layout Guidelines

- Bend Radius: Set it ≥ sheet metal thickness to avoid cracks.

- Bend Relief: Slits prevent sheet metal tearing.

- Flange Length: ≥ 4x sheet metal thickness for stability.

- 4T Rule: Keep features 4x sheet metal thickness from bends.

- Hole Layout: Holes ≥ 2x sheet metal thickness from edges.

DFM Design Review Checklist

| Design Aspect | DFM Guideline | Rationale | Common Mistake |

| Wall Thickness | Uniform thickness | Avoids machining | Varying sheet metalthickness |

| Bend Radius | ≥ Sheet metalthickness | Prevents cracking | Small radii |

| Bend Consistency | Same radius | Reduces tooling | Multiple radii |

| Flange Length | ≥ 4x Sheet metalthickness | Ensures stability | Short flanges |

| Hole/Feature Position | ≥ 4x Sheet metalthickness from bend | Prevents distortion | Features near bends |

| Hole Diameter | ≥ Sheet metalthickness | Ensures stability | Small holes |

| Standardization | Standard sizes | Lowers costs | Non-standard sheet |

| Part Consolidation | Combine parts | Reduces assembly | Separate sheet metalparts |

VII. Quality, Compliance, and Traceability: Building Trust

In my sheet metal projects, quality, compliance, and traceability are non-negotiable, especially for automotive and aerospace clients.

Quality Control

I rely on tools like CMM and 3D laser scanners to ensure sheet metal precision. Real-time data helps me catch issues early.

Certifications and Traceability

- ISO 9001: My baseline for sheet metal quality.

- IATF 16949: Keeps my automotive sheet metal defect-free.

- AS9100: Ensures aerospace sheet metal safety.

- Traceability: I track every sheet metal piece from raw material to delivery.

VIII. The Business of Sheet Metal: My Cost-Saving Tips

Understanding sheet metal costs is key to winning projects:

- Material Costs: 40–60% of sheet metal expenses.

- Estimation: I use software to quote sheet metal jobs fast.

- Automation: Robotic sheet metal welding pays off in two years.

IX. The Future of Sheet Metal Fabrication: What Excites Me

The sheet metal industry is evolving, and I’m thrilled to be part of it:

- Industry 4.0: AI and IoT make sheet metal production smarter.

- 3D Printing: Great for sheet metal prototypes, but traditional methods win for volume.

- Sustainability: I’m pushing for recycled sheet metal and energy-efficient lasers to cut waste.

Conclusion

Sheet metal has shaped my career, and I hope this guide inspires you to explore its potential. Ready to elevate your sheet metal project? Connect with our team at [insert link] for expert DFM advice and cutting-edge sheet metal solutions.

FAQ:

Q: What is the difference between sheet metal fabrication and stamping?

A: Fabrication is a broad term covering the entire process from cutting to assembly. Stamping is a specific high-efficiency forming process using dedicated dies, best suited for high-volume production.

Q: Which grade of aluminum or stainless steel should I choose for my project?

A: For stainless steel, 304 is a general-purpose grade, 316 has superior corrosion resistance, and 430 is lower cost. For aluminum, 6061 is strong and weldable, 5052 is resistant to marine environments, and 3003 has good formability.

Q: How thick can a CNC punch press handle?

A: As a rule of thumb, a typical CNC punch press can handle up to 3 mm stainless steel, 4 mm mild steel, and 5 mm aluminum.

Q: What is the “4T rule” in sheet metal design?

A: The 4T rule is a key DFM guideline stating that holes or other features should be at least 4 times the material thickness (4T) away from a bend line to prevent deformation.

Q: Why is ISO 9001 certification important for a sheet metal fabricator?

A: ISO 9001 certification indicates that a fabricator has a mature quality management system, ensuring consistent product quality, continuous improvement, and a focus on customer needs, which translates to higher reliability for the customer.

Q: How is the cost of a sheet metal part calculated?

A: The cost is determined by multiple factors, including material cost, processing cost (machine time x rate), setup cost, labor cost, finishing cost, and overhead.

Q: Is 3D printing cheaper than sheet metal fabrication?

A: It depends on the volume. For single prototypes or small batches, 3D printing is generally cheaper. For high-volume production, traditional sheet metal processes are far more cost-effective per part due to economies of scale.

Q: How does anodizing work?

A: Anodizing is an electrochemical process mainly for aluminum. The part is immersed in an acid electrolyte bath, and an electric current is passed through it, causing a hard, durable, and corrosion-resistant aluminum oxide layer to form on the surface. This layer can also be dyed.

Q: What is the powder coating process?

A: Powder coating is a dry finishing process. A part is first cleaned, then an electrostatically charged dry powder is sprayed onto the grounded part. Finally, the part is cured in an oven, where the powder melts and cross-links to form a tough, smooth coating.

Reference source:

https://en.wikipedia.org/wiki/Sheet_metal;

https://metalexponents.com/blog/common-applications-for-sheet-metal-in-construction/;

https://www.steelstackusa.com/blog/common-types-of-sheet-metal;

https://www.epa.gov/sustainability/sustainable-manufacturing;

Other Articles You Might Enjoy

- Sheet Metal Fabrication for Automotive Industry

Introduction to Sheet Metal Fabrication in the Automotive Industry Sheet metal fabrication is a cornerstone process in the automotive industry, essential for constructing vehicle frames, bodies, and components. It involves…

- Advanced Sheet Metal Fabrication Solutions for the Electronic Sector

Sheet metal fabrication stands as a crucial process within the electronics industry, instrumental in crafting a plethora of components that underpin electronic devices. This technique involves shaping and joining metal…

- Tips on Minimizing The Cost of Sheet Metal Fabrication

Sheet metal fabrication refers to a variety of manufacturing processes that are used to create sheet metal. We can use multiple processes, including bending, punching, and welding, to create intricate…

- Prototype CNC Machining of Brass: Reliable and Affordable Services

Introduction to Prototype CNC Machining of Brass In the world of manufacturing, prototype CNC machining plays a crucial role. This technology-based process brings ideas into tangible reality by creating precise…

- 5-Axis CNC Machining Aluminum Parts: Efficient Production

Introduction to CNC Machining and Its Relevance in the Manufacturing Industry CNC machining, an abbreviation for Computer Numerical Control machining, is a manufacturing technique integral to producing high-precision parts at…

- Aluminum Plate for CNC Projects: A Practical Buying and Application Guide

Introduction If you've ever worked on a CNC project—whether in a garage workshop or a full-scale production facility—chances are you've handled an aluminum plate. I remember the first time I used…