Introduction to Wire EDM:

In my years working with advanced manufacturing, I’ve seen countless machining challenges—parts too intricate, materials too hard, or tolerances too tight for traditional methods. That’s where wire electrical discharge machining (Wire EDM) shines. This non-contact process uses a thin, electrically charged wire to slice through conductive materials with pinpoint accuracy. Sparks, reaching temperatures of 12,000°C, vaporize tiny material particles along a CNC-programmed path without the wire ever touching the workpiece. Wire EDM transforms tough materials like titanium and tungsten carbide into complex shapes, delivering stress-free, mirror-like finishes. As a cornerstone of CNC machining, it empowers industries like aerospace, medical, and electronics to push design boundaries. This guide shares my insights into wire-cut EDM, blending technical depth with firsthand experience.

The Evolution of Spark Erosion: How Wire EDM Began

The spark that ignited Wire EDM dates back to 1770 when Joseph Priestley noted electricity’s erosive power. By the 1940s, Soviet researchers B.R. and N.I. Lazarenko harnessed this to machine tungsten, while an American team tackled broken tools in castings. The 1960s brought wire-cut EDM, using a moving wire to craft precise shapes in hardened steel for tool and die work. The real game-changer came in the 1970s with CNC integration, which I’ve seen revolutionize CNC machining. The USSR’s 1967 commercial machine marked a turning point, making Wire EDM a go-to for precision tasks. Reflecting on my early days in a machine shop, I was amazed at how this technology turned impossible designs into reality.

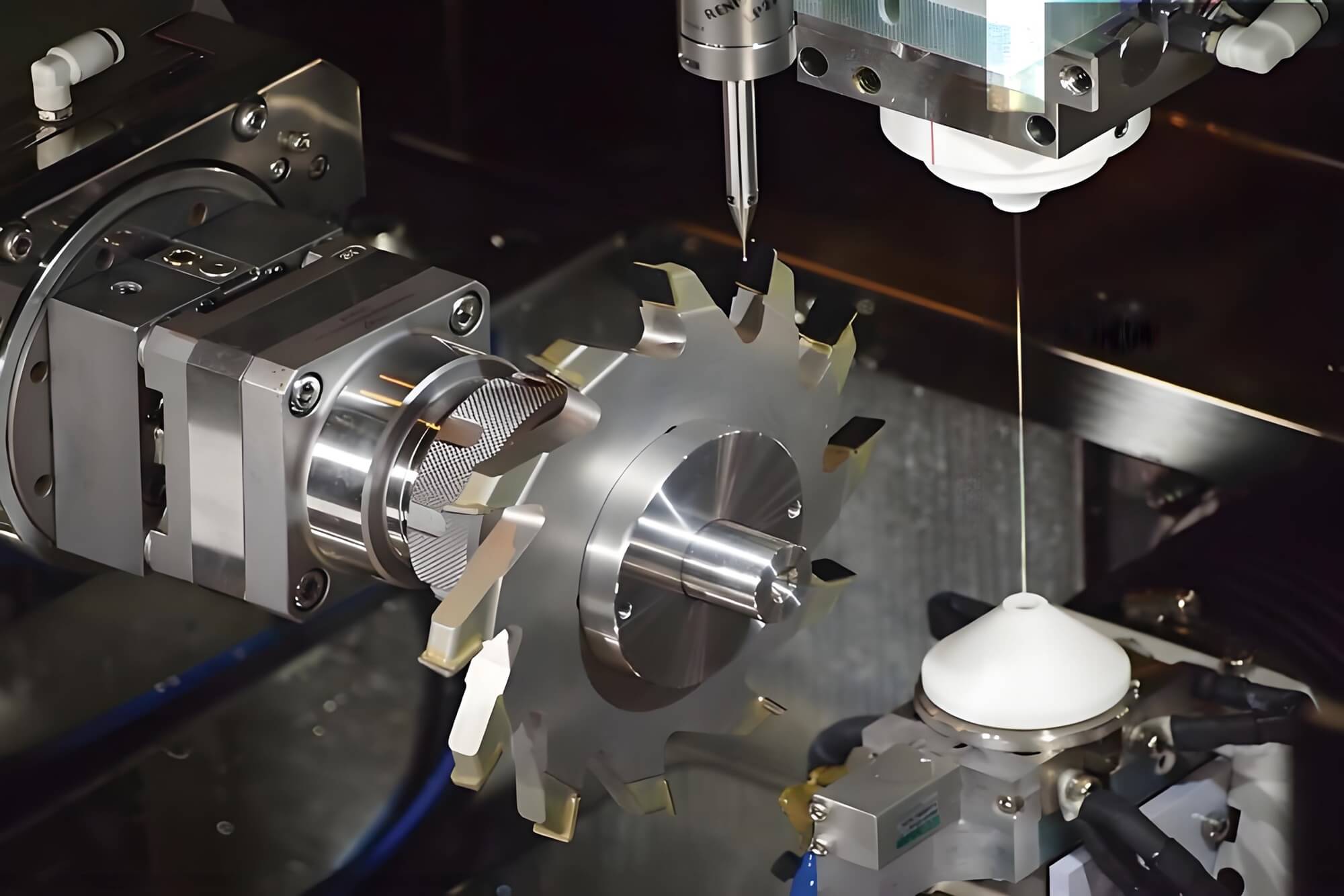

How Wire EDM Works: Precision in Action

From my perspective, Wire EDM is like conducting an orchestra of sparks. It starts with a CAD model, translated into a toolpath via CAM software. The workpiece, often a tough alloy, is mounted on a CNC-controlled table. For internal cuts, a starter hole is drilled—something I’ve watched machinists perfect to save setup time. The wire, threaded through by an Automatic Wire Threading system, is guided by diamond or ceramic guides. Submerged in deionized water, the setup controls sparks that erode material without contact. In my experience, the roughing pass is fast but coarse; the skim passes, though slower, deliver the precision that makes Wire EDM a standout in CNC machining. Those final passes are where the magic happens—parts emerge flawless, ready for critical applications.

Inside a Wire EDM Machine: A System of Precision

A wire EDM machine is a marvel of engineering, and I’ve spent hours marveling at its components. The CNC unit acts as the brain, directing every move. A high-frequency power supply generates the sparks, while the wire—often brass or coated—stays taut to avoid vibration. Diamond guides ensure pinpoint accuracy, especially for tapered cuts. The dielectric fluid system, with its pumps and chillers, keeps everything stable and clean. I recall a project where thermal stability was critical; the chiller’s role in maintaining consistent cuts was a lifesaver. This integration of CNC machining precision makes Wire EDM indispensable for complex tasks.

Why Wire EDM Stands Out: Unmatched Capabilities

In my view, Wire EDM isn’t about speed—it’s about doing what other CNC machining methods can’t. It achieves tolerances as tight as ±0.002 mm, perfect for intricate shapes like sharp corners or narrow slots. It cuts hardened materials post-heat treatment, avoiding distortion—a trick I’ve seen save countless aerospace projects. The burr-free finish often skips secondary polishing, and the stress-free process is ideal for delicate parts. I once worked on a thin-walled medical component; Wire EDM ensured it held its shape without deforming. The continuous wire eliminates tool wear, guaranteeing consistency across batches, making it a reliable choice in CNC machining.

Wire EDM in Action: Real-World Applications

Wire-cut EDM transforms industries. In tool and die making, it crafts precise molds and stamping dies. Aerospace relies on it for superalloy turbine blades, where I’ve seen it deliver flawless results under tight deadlines. In medical manufacturing, it produces burr-free surgical tools and implants—critical for patient safety. Electronics benefits from its micro-precision for MEMS components, and automotive uses it for complex parts like fuel injectors. I recall a project machining titanium implants; Wire EDM’s ability to handle such materials without compromise was a game-changer, reinforcing its role in advanced CNC machining.

Comparing Wire EDM to Other Technologies

Understanding Wire EDM’s niche requires comparison with other CNC machining methods. Below are tables detailing its strengths:

| Feature | Wire EDM | Sinker (Ram) EDM |

| Tooling (Electrode) | Thin, continuously moving wire (brass, coated) | Custom-shaped, solid electrode (graphite, copper) |

| Geometry Created | 2D/3D profiles, through-cuts, tapers | Complex 3D cavities, blind pockets, impressions |

| Principal Movement | X-Y axes (cutting from the side) | Z-axis (sinking from above) |

| Starting Point | Must start from an edge or pre-drilled starter hole | Can start anywhere on the surface |

| Typical Dielectric | Deionized Water | Hydrocarbon Oil |

| Primary Application | High-precision profiles, tools, dies, intricate parts | Molds, dies, blind cavities, 3D contouring |

| Feature | Wire EDM | CNC Milling |

| Cutting Mechanism | Thermal Erosion (no contact) | Mechanical Shearing (physical contact) |

| Cutting Force | None (stress-free) | Significant (can distort parts) |

| Hard Materials | Unaffected by hardness (e.g., hardened steel, carbide) | Difficult and slow; requires special tooling; causes high tool wear |

| Internal Corners | Can create sharp, near-zero radii | Limited by tool diameter, leaves a radius |

| Thin Walls/Features | Ideal, no risk of distortion | Risky, can cause vibration, breakage, or distortion |

| Surface Finish | Excellent, non-directional, burr-free | Good, but can have tool marks (“lay”) and may require deburring |

| Cutting Speed | Slower material removal rate | Faster material removal rate |

| Feature | Wire EDM | Laser Cutting | Abrasive Waterjet |

| Accuracy/Tolerance | ★★★★★ (±0.002mm – ±0.01mm) | ★★★★☆ (±0.025mm – ±0.1mm) | ★★★☆☆ (±0.1mm – ±0.2mm) |

| Material Capability | Conductive materials only | Most materials; struggles with reflective or very thick metals | Virtually any material (metal, stone, glass, composites) |

| Max Thickness | Very thick (>300mm / 12 in) | Thin to medium (<25mm / 1 in) | Very thick (>300mm / 12 in) |

| Cutting Speed | Slow | Very Fast (on thin material) | Fast (5-10x faster than EDM) |

| Heat-Affected Zone (HAZ) | Minimal/Slight Recast Layer | Moderate HAZ | None (Cold Cutting Process) |

| Kerf Width | Very Narrow (~0.1-0.3mm) | Narrow (~0.1-0.5mm) | Wider (~0.5-1.0mm) |

| Setup | Requires starter hole for internal cuts | Can pierce directly | Can pierce directly |

Wire EDM cuts 2D profiles, complementing Sinker EDM’s 3D cavities. Unlike CNC milling, it’s stress-free, ideal for hard materials. Compared to laser or waterjet, Wire EDM offers unmatched accuracy but is slower and limited to conductive materials.

Designing for Wire EDM: Practical Insights

From my experience, smart design saves time and cost in Wire EDM. The smallest corner radius depends on the wire and spark gap, so I advise specifying the largest acceptable radius to speed cuts. Internal cuts need starter holes, but starting from an edge eliminates this step—a trick I’ve used to streamline projects. Thicker parts slow cutting and may cause barreling, requiring extra skim passes. Leaving a tab to hold the part until the final cut ensures stability. For example, when designing a titanium aerospace component, I avoided tight radii to cut production time significantly, a lesson learned from trial and error in CNC machining.

Challenges of Wire EDM: What I’ve Learned

Wire EDM isn’t perfect. Its slow speed makes it less ideal for high-volume runs, something I’ve navigated when prioritizing precision over output. It’s limited to conductive materials, ruling out ceramics or plastics. Costs add up from wire, filters, and resin, and wire breakage can halt production—a frustration I’ve faced during tight schedules. The slight recast layer can also be an issue for high-fatigue parts, requiring extra finishing. Despite these hurdles, Wire EDM’s precision makes it worth the trade-offs in CNC machining.

The Future of Wire EDM: A Bright Horizon

Looking ahead, wire-cut EDM is evolving rapidly. Automation, like IoT and automatic threaders, enables lights-out operation, which I’ve seen boost shop efficiency. AI is transforming machines into self-optimizing systems, predicting wire breaks—a feature I wish I’d had on past projects. Hybrid manufacturing, pairing Wire EDM with 3D printing, is exciting; I’ve tested it for finishing printed parts with stunning results. Micro-Wire EDM is also growing for medical and electronics applications, and eco-friendly dielectrics align with sustainability goals, a trend I believe will shape the future of CNC machining.

Conclusion: Why Wire EDM Matters

In my career, Wire EDM has been a game-changer, turning impossible designs into reality with unmatched precision. Its ability to handle hard materials and complex shapes makes it vital for aerospace, medical, and electronics industries. As AI, automation, and hybrid systems advance, wire electrical discharge machining will only grow in impact. If you’re tackling a challenging project, I recommend exploring Wire EDM solutions.

FAQ:

1. What is Wire Electrical Discharge Machining (Wire EDM)?

Answer: Wire EDM is a non-contact CNC machining process that uses a thin, electrically charged wire to cut conductive materials with high precision. Controlled sparks, reaching up to 12,000°C, vaporize tiny material particles along a CNC-programmed path without the wire touching the workpiece. Submerged in deionized water, it achieves tolerances as tight as ±0.002 mm, ideal for complex shapes and hard materials like titanium or tungsten carbide.

2. What materials can Wire EDM process?

Answer: Wire EDM works only with conductive materials, such as hardened steel, titanium, tungsten carbide, aluminum, and copper. Non-conductive materials like ceramics, plastics, or glass are not compatible. From my experience, Wire EDM excels in handling superalloys for aerospace or biocompatible materials for medical applications, ensuring structural integrity.

3. How does Wire EDM compare to traditional CNC milling?

Answer: Unlike CNC milling, which uses mechanical cutting and can cause stress or distortion, Wire EDM is a non-contact thermal process, making it ideal for delicate or hard materials. It achieves sharper corners and tighter tolerances but is slower. Milling is faster for bulk material removal but struggles with hard materials due to tool wear. I once chose Wire EDM for a thin-walled part to avoid the vibration issues common in milling.

4. What are the key advantages of Wire EDM?

Answer: Wire EDM offers:

- Precision: Tolerances as tight as ±0.002 mm.

- Complex geometries: Sharp corners and narrow slots unattainable by other methods.

- Hard material processing: Cuts post-heat-treated steel or titanium without distortion.

- Stress-free: Perfect for fragile parts.

- Superior finish: Burr-free surfaces often require no polishing.

In a medical project, Wire EDM delivered implant surfaces so smooth they met stringent biocompatibility standards without extra finishing.

5. What are the limitations of Wire EDM?

Answer: Wire EDM has trade-offs:

- Slow speed: Less suitable for high-volume production.

- Conductive materials only: Excludes ceramics or plastics.

- High costs: Wire, filters, and resin increase expenses.

- Wire breakage risk: Can disrupt production.

- Recast layer: A minor heat-affected zone may need removal for high-fatigue parts.

I’ve faced wire breakage during a tight deadline, underscoring the need for optimized settings to maintain efficiency.

6. Which industries rely on Wire EDM?

Answer: Wire EDM is vital in:

- Tool and die: Crafting precise molds and stamping dies.

- Aerospace: Shaping superalloy turbine blades.

- Medical: Producing burr-free surgical tools and implants.

- Electronics: Fabricating micro-components for MEMS.

- Automotive: Making fuel injectors and gearbox parts.

In an aerospace project, Wire EDM ensured turbine blades met exacting tolerances, critical for engine performance.

7. How can I optimize designs for Wire EDM?

Answer: To streamline Wire EDM and reduce costs:

- Corner radius: Specify the largest acceptable radius to speed cutting, as the minimum depends on wire size and spark gap.

- Starter holes: Plan for pre-drilled holes for internal cuts or start from an edge to skip this step.

- Thickness: Account for slower cutting in thicker parts, which may require extra skim passes to correct barreling.

- Tabs: Use small tabs to stabilize parts until the final cut.

In a titanium component project, I adjusted corner radii to cut processing time significantly, a lesson from hands-on CNC machining experience.

8. How does Wire EDM compare to Sinker EDM, laser cutting, and waterjet cutting?

Answer:

- Sinker EDM: Complements Wire EDM by creating 3D cavities, while Wire EDM focuses on 2D/3D profiles.

- Laser cutting: Faster for thin materials but less precise (±0.025 mm) and struggles with reflective metals.

- Waterjet cutting: Cuts any material with no heat-affected zone but offers lower precision (±0.1 mm).

Wire EDM provides unmatched accuracy (±0.002 mm) but is slower and limited to conductive materials. I’ve chosen Wire EDM over laser for precision-critical parts, prioritizing quality over speed.

Reference:

https://www.youtube.com/watch?v=TKrfpFdg7F4;

https://itsupplychain.com/conventional-edm-vs-wire-edm-the-main-benefits/;

https://reprap.org/wiki/Electrical_Discharge_Machining;

Other Articles You Might Enjoy

- Unveiling the Wonders of Wire EDM: Masterful Precision Machining for Intricate Components

Wire Electrical Discharge Machining (EDM) is a specialized manufacturing process where electrical discharges are used to cut metals with high precision, shaping intricate contours and patterns that would be difficult…

- Sinker EDM vs Wire EDM: Key Differences and Applications

Introduction to Electrical Discharge Machining (EDM) Electrical Discharge Machining, commonly known as EDM, is an advanced machining technique used to shape hard metals and other conductive materials through the use…

- Electrical Discharge Machining (EDM) Basics: Process, Benefits, and Multidisciplinary Applications

Introduction to Electrical Discharge Machining (EDM) Electrical Discharge Machining, commonly referred to as EDM, is a non-traditional machining method that employs electrical discharges or sparks to remove material from a…

- How to Choose the Best EDM Machine for Your Manufacturing Needs

Why Choosing the Right EDM Machine Matters When I first explored the world of EDM machines, I quickly realized their transformative potential in modern manufacturing. These machines go beyond the…