Introduction to CNC Machining and Its Importance

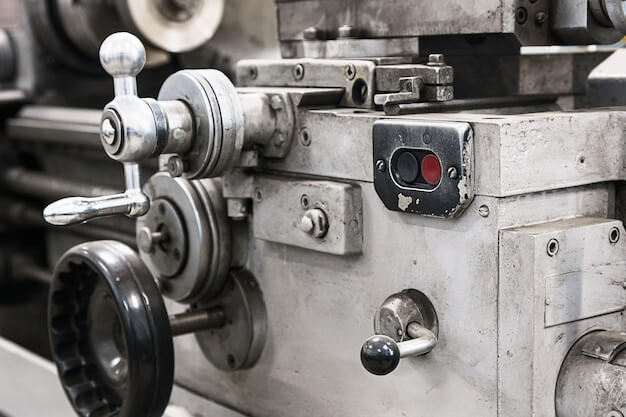

CNC (Computer Numerical Control) machining is a production process where pre-set computer software dictates the movement of factory tools and machinery. It offers precise control of design parameters, enabling the creation of custom parts and components with superior accuracy and speed. This automated machining yields highly consistent and efficient results, making it an essential tool in various industries like automotive, aerospace, and electronics.

When manufacturing complex parts such as steel and titanium components, obtaining online quotes for CNC machining is vital. This encompasses several benefits:

-

To help understand the cost breakdown: Accurate understanding of material costs, labor wages, and overhead expenses are possible.

-

Enabling price comparison: By receiving multiple quotes, you can compare prices and opt for the most economical offer without compromising quality.

-

Saving time: Online quoting speeds up the procurement process, eliminating extensive wait times associated with traditional quotation methods.

Understanding Online CNC Machining Quotes

Online Computer Numerical Control (CNC) machining quotes are digital quotations given by manufacturers for specific projects involving the production of steel and titanium components. These quotes provide a detailed outline for potential costs, including material sourcing, customization features, precision in tooling, labor costs, and shipping considerations. Understanding these online quotes is vital for the manufacturing process since they serve as an accurate cost estimate, help in budget planning, and guide decision-making on fabrication techniques.

- The concept of online CNC machining quotations requires knowledge of individual projects’ specifics to generate accurate cost estimates for necessary materials, processes, and labor.

- They are crucial in manufacturing steel and titanium components as they allow both producers and consumers to understand the economic feasibility of particular design choices or procedures.

- For instance, when planning to manufacture a complex titanium component with high precision requirements, an online quote would provide insights into whether it’s more cost-effective to use multi-axis milling versus traditional CNC lathing.

Factors affecting the price of steel and titanium components include:

- Material Selection: The cost of steel and titanium varies based on the grade and specific properties required for the components.

- Manufacturing Complexity: Intricate designs and tight tolerances may increase the machining time and labor costs for both steel and titanium parts.

- Post-Processing Treatments: Surface finishing and additional treatments can add to the overall cost of steel and titanium components.

- Market Pricing: Fluctuations in the market prices of steel and titanium can impact the overall cost of manufacturing components.

For precision machining services, consider utilizing an online CNC service to ensure high-quality and accurate steel and titanium components.

Steps Involved in Getting an Online CNC Machining Quote

To acquire online CNC machining quotes for steel and titanium components, the first step involves logging onto a company’s CNC services website. Here you are required to upload your CAD files specifying the design details and desired material. This is followed by making selections regarding the kind of machinery process required such as milling or turning, surface finishes, heat treatments and quantity of the parts needed. After confirming these selections, you can proceed to request a quote. Once submitted, CNC specialists will review and evaluate your specifications before sending a detailed proposal which breaks down the cost and time frame for production.

An example of obtaining a real-life online quote would be Mr. Smith, a mechanical engineer working on a custom car project. Mr. Smith had developed a unique titanium wheel hub in his CAD software and wanted it machined. He logged into XYZ CNC services’ website, uploaded his CAD file, chose 5-axis CNC milling, opted for bead blasting finish, and selected a quantity of four. Shortly after submitting his request, he received a comprehensive quote outlining not only the costs but also the timeline for production.

Comparison between Steel and Titanium Component Quoting

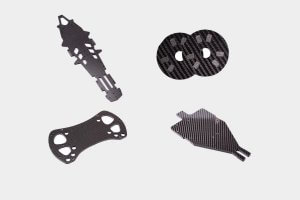

In the realm of online CNC machining quotes, the pricing varies significantly when comparing steel and titanium components. This variation is generally due to the inherent differences in material properties and processing requirements.

- Steel, being prevalent and relatively easy to machine, usually has a lower quote compared to titanium. For instance, a 5-inch diameter simple design gear may be quoted around $60-$75 for steel.

- On the other hand, titanium’s lighter weight, higher strength-to-weight ratio and corrosion resistance make it far more desirable for certain applications such as aerospace or medical technology; but these advantages come at a cost. Machining titanium requires specialized tooling and slower speeds due to its tough characteristics, which consequently drive up labor costs and lead time. A similar gear made of titanium could well result in a price upwards of $150 depending on complexity.

Therefore, the choice between steel and titanium largely depends on the desired balance between component performance and budget constraints.

Potential Challenges in Online CNC Machining for New Users

Novice users may face several challenges while using online Computer Numerical Control (CNC) machining services. The primary issues involve understanding technical terminologies, selecting the appropriate materials and components, configuring machine parameters correctly, interpreting design specifications, and managing cost and time constraints. To overcome these obstacles, new users are advised to familiarize themselves with basic CNC concepts and terminologies by utilizing available educational resources such as online tutorials or user manuals.

The next step involves selecting suitable materials and tools. Users should pay keen attention to material properties and tool compatibility with their specific project requirements. A commonly adopted practice is conducting a small test run before committing to large-scale production.

Familiarity with CAD software and understanding design feasibility significantly enhance process efficiency. Consulting with experienced professionals can provide valuable insights regarding this aspect. Adopting systematic planning methods such as Gantt charts could also assist in effectively navigating timelines and financial aspects of projects.

- Challenges: Understanding Technicalities, Material and Equipment Selection, Design Feasibility, Time and Cost Management

- Solutions: Utilizing Educational Resources, Expert Consultation, Systematic Planning Methods

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Breaking Barriers in CNC Machined Aerospace Structures

Introduction: CNC Machining in Aerospace Structures In the aerospace industry, accuracy, reliability and efficiency are paramount. To maintain these standards, modern day aerospace manufacturing heavily leans on Computer Numerical Control…