CNC Machining and the Importance of Material Selection

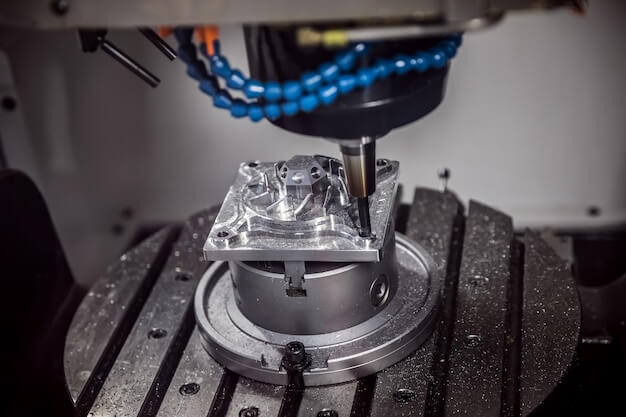

Computer Numerical Control (CNC) machining is a prevalent method in manufacturing where pre-programmed computer software regulates the movement of factory machinery. This advanced technology enables control over complex cutting tasks, presenting a drastic evolution from manual manipulation. However, an integral segment of successful CNC machining centers around choosing the appropriate material for both the project’s requirements and machine characteristics.

- For instance, materials such as copper boast excellent thermal and electrical conductivity which make them ideal for electronic components while aluminum brings factors like corrosion resistance combined with notably lighter weight into consideration for aerospace applications.

Understanding Material Conductivity in Manufacturing

In the process of CNC machining, material conductivity plays a significant role. Essentially, it refers to the ability of a certain material to transmit heat or electricity. This property is pivotal as it greatly impacts the performance, productivity and overall result of the manufacturing process. Variations in material conductivities can lead to different outcomes on two primary factors – machine speed rate and quality of final product.

- Machine Speed Rate: Typically, materials with high conductivity such as copper can be machined at higher speeds since they facilitate rapid heat dissipation. This translates to less wear and tear on the machine tool, thereby enhancing efficiency and productivity.

- Quality of Final Product: The choice of material also influences the precision and accuracy of CNC operations. For instance, Aluminum, although having lower conductivity than copper, presents ease of machinability resulting in more exacting dimensions and finishes.

This underlines the necessity for manufacturers to understand and gauge material conductivity while deciding upon the most suitable metal for a specific manufacturing task.

Detailed Analysis of Copper: Advantages and Limitations

When it comes to CNC machining, copper is a widely used material that offers several advantages and limitations. Here is a step-by-step analysis of the benefits and considerations of using copper in CNC machining:

1. Advantages of Copper:

- Copper has high thermal and electrical conductivity, making it an excellent choice for applications that require efficient heat dissipation and electrical conductivity.

- It has excellent machinability, allowing for precise and intricate machining of complex parts.

- Copper exhibits good corrosion resistance, ensuring the longevity and durability of CNC machined parts.

- It is a recyclable material, aligning with sustainability goals and reducing environmental impact.

2. Limitations of Copper:

- Copper has poor electrical conductivity compared to materials like aluminum.

- It is a relatively soft material, which can limit its use in certain applications that require high strength or wear resistance.

- Copper is more expensive compared to some other materials used in CNC machining.

Considering the advantages and limitations of copper is crucial when making material choices for CNC machining projects. While copper offers excellent thermal and electrical conductivity, machinability, corrosion resistance, and recyclability, its limitations in terms of electrical conductivity, softness, and cost should be taken into account. To optimize the use of copper in CNC machining and access professional CNC machining services, you can rely on our online CNC service or precision machining service.

Detailed Analysis of Aluminum: Pros and Cons

Aluminum, known for its high thermal and electrical conductivity properties, plays a significant role in CNC machining. It brings distinctive advantages such as lightweight nature, corrosion resistance, and excellent machinability which facilitates faster cutting speeds, reduced wear on tools, and shorter production cycles – thereby increasing efficiency. Further, the material’s ability to conduct heat effectively allows effective cooling during arduous machining tasks.

- Benefits: Its non-toxic and recyclable elements make aluminum an environmentally friendly choice for CNC machining tasks. Moreover, the cost-effectiveness attached with this metal outclasses most of its counterparts, making it an economical option that doesn’t compromise on quality or functionality.

However, using aluminum is not without challenges. Although it’s generally easy to work with, there are potential obstacles that need tackling.

- Potential Obstacles: The softness of aluminum can lead to burring during machining. This requires additional post-machining processes to achieve a smooth finish, potentially extending production time. Additionally, certain types of aluminum alloys produce fine chips during machining, necessitating adequate chip evacuation strategies to prevent clogging and possible damage to the machine components.

Direct Comparison of Copper and Aluminum Efficiency in CNC Machining

In a comparative analysis of performance indicators: speed, precision, and energy use, there are substantial differences that delineate copper’s efficiency from aluminum in CNC machining. Moreover, while both materials have their own sets of advantages, the extent of how they perform under various conditions strongly depends on their material conductivity.

Copper, for instance, is known for its fast heat transfer which often results in high-speed machining with quick thermal changes. This property makes it an excellent choice for operations requiring detailed cuts or intricate designs due to its precise tooling capability. However, this also comes at the cost of higher energy consumption because of the conducting material’s inherent demand for more power.

Conversely, aluminum’s lower heat conductivity leads to slower machining speeds but with less significant thermal fluctuations which make it ideal for bulk cutting processes. The metal also boasts improved energy-efficiency as it necessitates lesser power compared to copper.

A clear example would be seen when using a 10 mm end mill bit for cutting identical pieces. While copper can reach the same depth faster due to its quick heat dissipation, aluminum needs more time, albeit still achieving similar results yet consuming significantly less energy. Therefore, the specific application plays a crucial role in determining whether copper’s speed and precision outweigh aluminum’s slower yet efficient operation.

The Role of Copper vs Aluminum Efficiency in Different Industries

In the arena of CNC machining, material selection plays a crucial role in ensuring efficiency and final product quality. Two commonly used metals are copper and aluminum, each boasting unique conductivity levels that lend themselves well to different industry specifics.

For instance, the electronics sector heavily favors copper for its superior electrical conductance capabilities, where modules like circuit boards utilize this metal to promote energy efficiency. On the other hand, the automotive industry often opts for aluminum due to its exemplary thermal conductivity which is integral in car radiator design and function by facilitating faster heat dispersion.

Real-Life Case Studies: Impact on Product Output due to Material Choice

- A case study of an electronics company replacing their traditional aluminum wiring with copper saw improvements in power consumption and overall device performance. This switch was credited primarily to copper’s heightened ability to conduct electricity efficiently.

- Conversely, a car manufacturing company opted to switch from copper to aluminum in the production of vehicle radiators. The result was surprisingly improved cooling performances observed in engines, affirming the importance of thermal conductivity provided by aluminum in such high-heat scenarios.

In conclusion, choices about material use significantly impact output across industries. Hence utilizing the respective strengths of both copper and aluminum depending on the requirement can greatly enhance product efficiency and functionality.

Other Articles You Might Enjoy

- Impact of Material Properties on CNC Machining Speeds and Feeds: Aluminum vs. Copper

Introduction to CNC Machining and its Importance in Manufacturing CNC machining, short for Computer Numerical Control machining, is a foundational technology utilized extensively in the national and international manufacturing sector.…

- Material Fatigue in CNC Machining: Steel vs. Aluminum Lifespan Analysis

Introduction to CNC Machining and Material Fatigue CNC or Computer Numerical Control machining is a manufacturing technique in which pre-programmed computer software controls the movement of factory tools and machinery.…

- Aluminum CNC Machining Service for Custom Parts

Aluminum CNC machining stands at the forefront of modern manufacturing, epitomizing precision, versatility, and efficiency. With its widespread applications across industries ranging from aerospace to automotive and beyond, aluminum CNC…