Introduction

Plastic laminate is a beautiful material when it’s done right—and a real nightmare when it isn’t. I’ve been working with CNC machines for years, and if there’s one thing I’ve learned, it’s that plastic laminate is not as easy to machine as people assume. It looks strong, clean, and finished on the outside, but it hides a fragile personality underneath.

When I first tried machining plastic laminate on a CNC router, I ended up with a half-burnt, chipped mess. The edges were blackened from heat. The top layer peeled back like a sticker. I remember thinking, “This can’t be how professionals do it.” Spoiler: It wasn’t.

This guide is what I wish I had back then. I’m going to walk you through how to avoid melting and delamination when working with plastic laminate, and how to get clean, pro-level results—even if you’re not a seasoned machinist.

Characteristics of Plastic Laminate

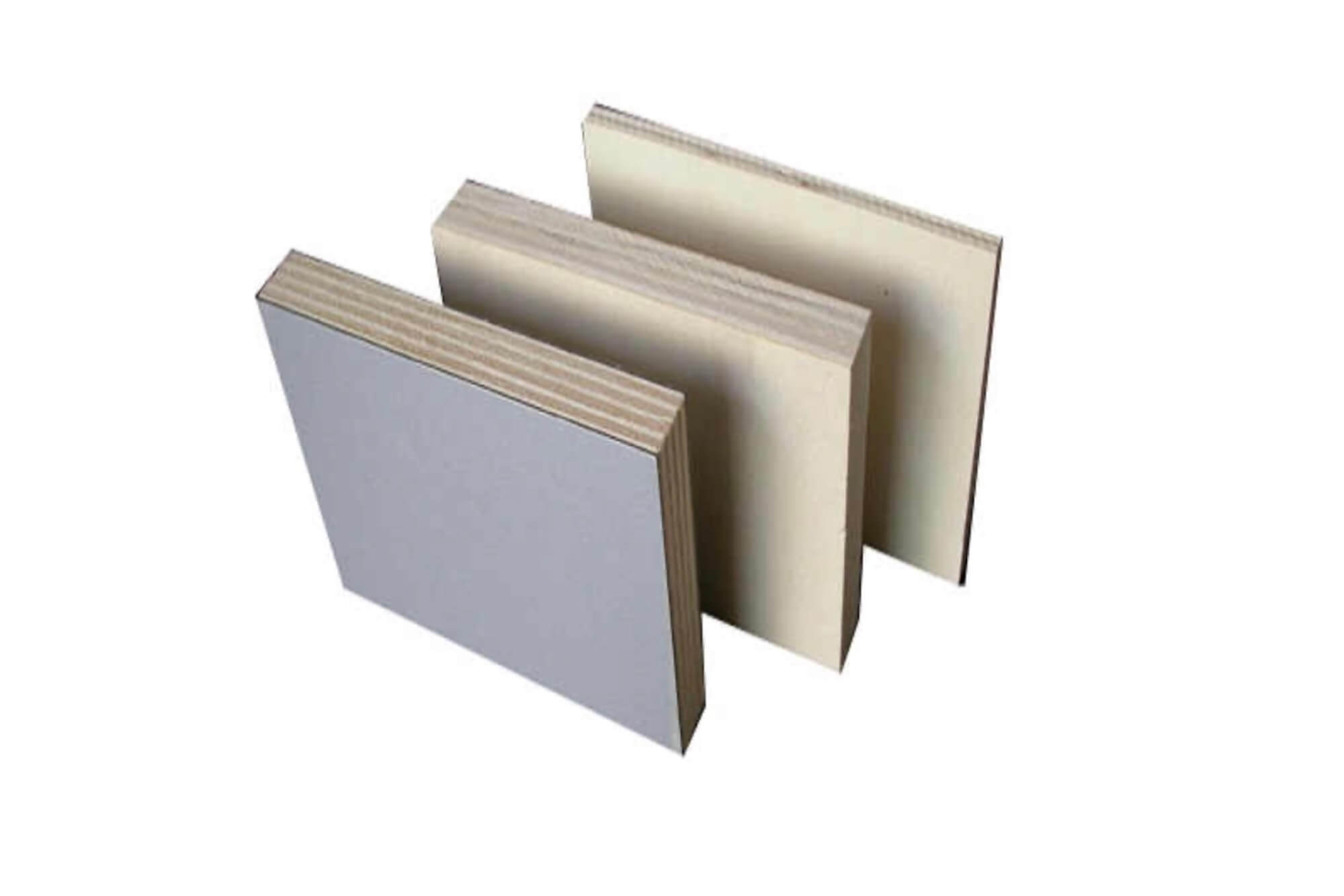

Plastic laminate is a layered material made by fusing a decorative surface paper with layers of kraft paper, all impregnated with resins. Most often, it’s bonded onto a core substrate like particle board or MDF. What you see as the shiny or matte surface is just a thin top layer—it looks durable, but it can be incredibly sensitive during CNC machining.

There are two common types:

| Type | Full Name | Thickness Range | Common Uses | Notes on CNC Machining |

|---|---|---|---|---|

| HPL | High-Pressure Laminate | 0.7–1.5 mm | Furniture, countertops | More heat-resistant, harder |

| LPL | Low-Pressure Laminate | 0.2–0.6 mm | Cabinets, shelving | More fragile, easier to chip |

| Melamine-coated | Paper or MDF core | 15–18 mm (with core) | Low-cost furniture | Brittle outer layer |

| Compact Laminate | Solid laminate sheet | 2–20 mm | Toilet partitions, lab tables | No wood core, very dense |

| Phenolic Board | Resin composite | 3–25 mm | Industrial applications | CNC-friendly, but expensive |

| PVC Laminate | Thermoplastic surface | 0.5–1.5 mm | Moisture-prone areas | Melts easily under friction |

The challenge in machining plastic laminate is that it behaves like both wood and plastic—and inherits the worst cutting traits from both. It can:

- Chip easily, especially along edges

- Melt when exposed to high spindle speeds or dull bits

- Delaminate, especially with dull tools or when not properly clamped

If you’re cutting it with CNC equipment, you need to be aware of how it reacts to friction, heat, pressure, and vibration. If not, you’ll waste expensive material—and worse, your time.

CNC Machining: Benefits and Challenges

I use CNC for almost every plastic laminate project now. It offers pinpoint accuracy and lets me create complex, repeatable parts at scale. But I had to learn (sometimes the hard way) how to adapt the CNC setup to match what plastic laminate needs.

✅ Benefits of Using CNC for Plastic Laminate

| Benefit | Why It Matters for Plastic Laminate |

|---|---|

| Precision cutting | Clean fits, accurate edge banding |

| Repeatability | Useful for cabinetry and mass production |

| Complex geometries | Works well for decorative routing |

| Automated toolpaths | Reduces human error and inconsistent force |

| Scalable production | Makes small-batch furniture cost-effective |

| Integration with CAD | Speeds up design-to-production workflow |

But here’s the catch: plastic laminate can turn on you fast. Heat builds up at the bit tip. Vibrations bounce back into the material. Bad clamping causes movement. And then, either the top layer bubbles, or the whole piece just melts at the edge, especially on tight inside corners.

❌ Common Problems When CNC Cutting Plastic Laminate

- Melting at edges

- Usually caused by high spindle speeds or dull bits

- You’ll notice black discoloration or resin deposits on the cut

- Delamination

- Top layer lifts or peels mid-cut

- Caused by aggressive feeds, poor adhesion, or low-quality laminate

- Chipping and Blowouts

- Especially on exit cuts or back side

- Often due to wrong tool type or direction of cut

- Tool wear and resin buildup

- Plastic laminate dulls bits faster than MDF

- Residue accumulates, causing overheating

Here’s a quick comparison I made in my own shop:

| Setting | Result with HPL | Result with LPL | Notes |

|---|---|---|---|

| High speed (18k) | Slight melting, resin buildup | Heavy chipping, edge burning | Tool was too fast, no cooling used |

| Low speed (10k) | Clean cut, light burr | Better finish, slight fuzz | Required two passes for best result |

| Dull bit | Edge tearing, smoke | Top layer ripped off | Lesson: always check tool sharpness |

| Compression bit | Crisp top and bottom edges | Very clean entry/exit | My go-to for laminate from then on |

After wrecking a few sheets and redoing parts from scratch, I’ve built my own method for machining plastic laminatethe right way. The next few chapters will walk you through machine setup, tooling choices, material handling, and real-life strategies that work.

Suitable CNC Machines for Plastic Laminate

Not all CNC machines are created equal—especially when it comes to cutting plastic laminate. I’ve tried at least four types of machines across two shops, and while they all technically can cut laminate, only one gave me consistent, clean results without melting or delamination.

Let’s break down which CNC systems are most suitable for plastic laminate machining.

🛠️ Types of CNC Machines and Their Fit for Plastic Laminate

| CNC Machine Type | Good for Plastic Laminate? | Why/Why Not |

|---|---|---|

| CNC Router (gantry) | ✅ Yes | Best fit; high speed, variable bits, large table sizes |

| CNC Laser Cutter | ❌ No (for most laminates) | Laminates often melt or release fumes under laser heat |

| CNC Plasma Cutter | ❌ No | Not compatible with wood or plastic-based laminates |

| CNC Waterjet | ⚠️ Limited use | Great edge quality but overkill; expensive and messy |

| CNC Knife Cutter | ❌ No | Can’t cut through laminated wood or thick surfaces |

If you’re working with full-size plastic laminate panels, I recommend a CNC router with at least:

- Spindle power of 2.2kW or higher

- Variable speed control (important for reducing melt)

- Vacuum table (to keep thin sheets flat)

- Tool change system (if switching between compression and upcut bits)

✅ My Shop Setup

In my own workshop, I use a 4’x8’ CNC router with vacuum hold-down and an automatic tool changer. It’s nothing exotic, but it’s configured well for plastic laminate jobs. I’ve added side dust collection brushes and auxiliary air blast nozzles, which help clear chips before they build up and melt back onto the laminate.

🔍 Tips When Choosing a CNC for Plastic Laminate:

- Rigid frame – Cheap, shaky frames will vibrate and cause delamination.

- Speed control – You need to slow things down to avoid heat.

- Dust collection – Laminate dust is fine and sticky; get a proper system.

- Soft start/spindle ramp-up – Prevents jarring at the tool entry point.

- Test first – Not all “woodworking” CNCs handle laminate equally well.

One mistake I made early on was trying to use an entry-level desktop CNC on a melamine-coated panel. The result? The vibration was so bad that the surface cracked before the cut even finished. Lesson learned.

Tooling and Cutting Parameters

Here’s the part that changed everything for me. I used to think any carbide bit would work. Wrong. Once I started investing in the right tooling, my quality jumped and my scrap rate dropped. Tooling—and the way you use it—is the most critical part of machining plastic laminate successfully.

🧰 Best Router Bits for Plastic Laminate

| Tool Type | Works Well For | Pros | Cons |

|---|---|---|---|

| Compression bit | HPL, LPL, melamine | Clean top and bottom edge | Expensive, needs correct direction |

| Single-flute upcut | Thin laminate or engraving | Good chip removal | May cause edge chipping |

| Straight double flute | General cuts | Stable, affordable | Risk of top layer lifting |

| Downcut bit | Thin veneer sheets | Keeps top layer intact | Can trap chips, causes burning |

| O-flute (plastic bit) | PVC laminate | Reduces melting, polished edge | Not ideal for thicker materials |

I personally use compression bits for 80% of my plastic laminate work. The beauty of a compression bit is that it pulls the top layer down and the bottom layer up as it cuts. This sandwich effect prevents chipping on both faces. When I switched to a compression bit, my sanding time was cut in half.

🧪 Cutting Parameters that Matter

Let me show you a table based on actual runs I’ve done on my CNC router with HPL and LPL:

| Material Type | Spindle Speed (RPM) | Feed Rate (mm/min) | Pass Depth (mm) | Result Summary |

|---|---|---|---|---|

| HPL on MDF | 14,000 | 3,000 | 3.0 | Clean edges, no melt |

| LPL on Particleboard | 12,000 | 2,500 | 2.5 | Slight fuzz on bottom |

| Melamine (2 sides) | 10,000 | 2,200 | 2.0 | Sharp corners chipped |

| PVC laminate | 9,000 | 1,800 | 1.5 | Clean cut, minimal heat buildup |

| HPL (dense core) | 15,000 | 3,500 | 3.5 | Resin buildup on bit after 3 runs |

| HPL with downcut | 11,000 | 2,800 | 2.5 | Top surface very clean |

The key takeaway: slower speeds and moderate feed rates help minimize melting. Always do a test cut. Always clean your bits. And never assume you can use the same settings from MDF or plywood—plastic laminate demands its own setup.

🧼 Extra Notes:

- Lubrication: I use an air blast system—misting is optional, but I avoid using liquid coolants unless I’m running PVC laminate in large batches.

- Tool life: I replace compression bits after ~30 sheets or sooner if I notice edge browning.

- Chip evacuation: Use a spiral bit or upcut feature to help push chips out fast.

I also keep a magnifying lens at my workstation to examine the edge finish after each new job. If I see burrs, melted resin, or fiber lifting—back to adjusting parameters I go.

Workholding Techniques

I used to underestimate how important clamping is when machining plastic laminate. Until one day, a panel lifted mid-cut and tore half the top laminate layer with it. That was a $45 mistake I never repeated. Holding your material flat and still is just as critical as your tooling and speeds.

The problem with plastic laminate sheets is they’re often thin, slick, and flexible—especially the unbonded types. Even if they’re glued to MDF or particleboard, vibration from poor clamping can cause micro-shifts. That’s where delamination starts.

🧲 Clamping Methods I Use and Recommend

| Method | Best For | Pros | Cons |

|---|---|---|---|

| Vacuum Table | Flat, full-size panels | Even support, no clamp marks | Requires good seal and maintenance |

| Double-Sided Tape | Thin or small parts | Quick setup | Tape residue, limited hold |

| Mechanical Clamps | Bonded laminate on substrate | Strongest hold | May leave marks or dents |

| MDF Spoilboard + Screws | Substrate boards | Custom jig options | Slower setup, not for thin sheets |

| Masking Tape + CA Glue | Small parts | Great for engraving cuts | One-time use, needs precise placement |

My go-to for full 4’x8’ sheets is a vacuum table with a sealed MDF spoilboard. I create “zones” on the board depending on part layout, to minimize air loss. For narrow strips or corners where vacuum is weak, I add mechanical hold-down clamps or even weight bars.

One tip I learned: if your vacuum isn’t strong enough, you can use masking tape + CA glue to temporarily bond small pieces for routing. I’ve used that trick for cutting custom cabinet handles from PVC laminate with no issues.

⚠️ Mistakes to Avoid

- Never clamp just the corners—vibration will ruin the center.

- Don’t over-tighten clamps on plastic laminate—it can crush the surface.

- Avoid using clamps without a spoilboard; your tool might hit metal.

I once saw a shop use soft foam strips as underlay for thin laminates to absorb vibration. Smart idea. I later adopted it for some melamine panels, and it reduced chipping noticeably.

📌 Bonus Tip: Anti-Slip Sheets

For loose plastic laminate sheets (not bonded to any board), I place a silicone anti-slip pad underneath. It adds just enough friction during light cuts like scoring or engraving.

Surface Quality and Edge Finishing

Even with the best feed rates and sharpest bits, you’ll likely need to do some edge cleanup. When I first started machining plastic laminate, I didn’t plan for finishing—and I ended up with fuzzy or sharp corners that were a hazard in client installations.

To me, a clean edge is the signature of a pro job.

🧽 Post-Cut Edge Treatments

| Finishing Method | Best For | Tools Needed | Comments |

|---|---|---|---|

| Light sanding | Minor burrs and fuzz | 400–600 grit sanding block | Sand lightly to avoid rounding |

| File or deburring tool | Thicker laminate sheets | Flat file, plastic edge tool | Follow direction of cut |

| Edge banding | Furniture and cabinetry | Edge bander or hot iron + glue | Matches design, hides substrate |

| Flame polishing | PVC laminate edges | Butane torch (careful!) | Not for wood-core materials |

| Polishing compound | Decorative visible edges | Buffer pad or cloth + polish | Adds shine, removes residue |

I personally keep a set of hand files in different grades. A few light strokes clean up most compression bit cuts. For melamine, a soft sanding block works wonders. Just don’t sand the top surface—it’s decorative and easy to ruin.

🎯 Tips for Professional Edge Quality

- Always cut with climb milling if your CNC allows it—better edge finish.

- Slow down feed rate on finishing pass (I do 0.5 mm step-down pass last).

- For double-sided laminated boards, use compression bits only.

- If you see frayed corners, switch to a sharper bit or reduce RPM.

🧼 Cleaning Tips

Dust sticks to plastic laminate like crazy. I keep a microfiber cloth and isopropyl alcohol spray nearby. It helps clean the edges without softening glue or paint. For sticky residue from masking tape, I use citrus-based adhesive remover.

And trust me—clients will run their fingers along the edges of anything you install. If it feels rough or sharp, you’ll hear about it.

Common Applications and Case Studies

I’ve worked on hundreds of CNC jobs, but when it comes to plastic laminate, the requests usually fall into three buckets: custom cabinetry, commercial display fixtures, and wall panel systems. Plastic laminate is versatile—it gives a sleek, durable finish, especially when you don’t want to spend big on natural veneer or metal.

Let me walk you through some typical real-world projects, where CNC machining plastic laminate was the ideal solution.

🛋️ A. Custom Kitchen Cabinets

We once had a client who wanted high-gloss white plastic laminate for all the kitchen fronts, including curved corner cabinets. Traditional edge trimming wasn’t working. With CNC, we used a compression bit to get clean curved contours, and it cut finishing time in half.

Key takeaways:

- Used 18mm MDF laminated with white HPL

- Nested panel layout to minimize waste

- Added pilot holes for concealed hinges on the CNC

- Final edge finish: heat-melt edge banding for durability

That job led to three referrals.

🛒 B. Commercial Retail Displays

For a pop-up cosmetics brand, we machined black matte plastic laminate panels to build modular retail shelving. Each module had dovetail joints and invisible fasteners.

| Component | Material Type | CNC Use | Notes |

|---|---|---|---|

| Display panels | 12mm MDF + LPL | Cutouts + engraving | Branding engraved into face |

| Base frames | Plywood + HPL | Precision joinery | Compression bit used |

| Sign boards | PVC laminate | Cut letters + logos | Flame polished for shine |

One cool trick: we engraved their logo into the laminate surface using a shallow v-bit path, then filled it with silver epoxy. The contrast looked amazing.

🏢 C. Wall Paneling for Corporate Interiors

In a recent office buildout, we used gray textured plastic laminate bonded to MDF for floor-to-ceiling wall panels. The client wanted a seamless look, so we chamfered every edge on the CNC.

Why CNC mattered here:

- Consistency in 35 identical wall segments

- Integrated cutouts for light switches, vents, data ports

- Pre-drilled mounting slots saved time during install

Plastic laminate made the space feel modern and clean, but was much cheaper than using real wood or metal panels.

📌 Lessons from These Projects

- Nesting and path optimization saved 15–20% material cost

- Using compression bits significantly reduced post-processing

- CNC pre-drilling for fixtures saves a ton of labor on-site

- Laminates can be artistic too—don’t be afraid to engrave

Whether you’re a small shop or a large-scale fabricator, plastic laminate combined with CNC opens up opportunities for speed, scale, and creativity.

Safety Precautions and Waste Management

I want to be upfront here—working with plastic laminate isn’t without hazards. The fine dust, adhesive fumes, and occasional melting can create a risky environment if you’re not careful. Over the years, I’ve built a checklist to make sure my workshop stays safe and clean.

🧯 A. Safety Guidelines for Machining Plastic Laminate

| Area | Best Practice | Why It Matters |

|---|---|---|

| Dust Collection | Use a two-stage extractor with HEPA filtration | Laminate dust is super fine |

| Ventilation | Open airflow or local exhaust when cutting PVC | Avoid inhaling fumes or off-gassing |

| Eye Protection | Always wear safety glasses | Plastic chips can fly unpredictably |

| Ear Protection | CNC routers are loud, especially with vacuum hold | Avoid long-term hearing damage |

| Fire Safety | Never leave a laser cutter unattended with laminate | Many types can ignite when overheated |

I once saw a friend’s laser job go bad—cutting dark plastic laminate at full power, it caught fire and melted the honeycomb bed. That was an expensive lesson.

♻️ B. Managing Plastic Laminate Waste

Plastic laminate isn’t always recyclable through municipal programs, but that doesn’t mean it has to go to landfill. Here’s how I handle it:

| Waste Type | Disposal Method | Notes |

|---|---|---|

| Offcut strips (usable) | Save for sample kits | Great for future mockups |

| Large but irregular panels | Donate to maker spaces | Hobbyists can repurpose them |

| Scraps with adhesive residue | Industrial waste bin | Check local codes for classification |

| Dust from CNC collection | Bag and label for disposal | Not safe for compost or reuse |

| Laminated MDF/particleboard | Separate if possible | Mixed waste may need special handling |

I also try to nest parts tightly and reduce toolpaths that cause unnecessary waste. Switching to digital part nesting software reduced my waste rate by about 18% over six months.

Supplier and Material Recommendations

When it comes to plastic laminate, not all materials are created equal. Over the years, I’ve tested dozens of brands, and there are clear differences in durability, CNC compatibility, and surface quality. A low-quality laminate will chip, curl, or even delaminate under stress—no matter how careful you are.

So here’s what I personally recommend based on what’s worked best in my shop.

🧾 Trusted Plastic Laminate Brands

| Brand | Origin | Surface Options | CNC Compatibility | Notes |

|---|---|---|---|---|

| Formica | USA | Glossy, matte, textured | ✅ Excellent | Consistent thickness, very durable |

| Wilsonart | USA | Wide color selection | ✅ Excellent | Easy to bond to MDF, smooth finish |

| FunderMax | Austria | Compact laminate options | ✅ Great (dense) | Best for wall cladding or partitions |

| Merino | India | PVC and acrylic laminates | ⚠️ Mixed results | Some types prone to melting |

| Greenlam | India/Global | HPL/LPL variety | ✅ Good | Affordable but may need slower speeds |

| Stylam | India/Export | Anti-fingerprint surfaces | ✅ Good | Smooth cuts but brittle at edges |

From my experience, Formica and Wilsonart are my go-to brands. They’re CNC-friendly and rarely cause issues with melting or delamination—assuming you’ve dialed in the right parameters.

🧰 CNC Tooling Suppliers I Trust

| Supplier/Brand | Country | Notable Products | My Use Case |

|---|---|---|---|

| Amana Tool | USA | Compression bits, O-flutes | My main supplier for laminate jobs |

| Freud | Italy | Carbide spirals | Good value for everyday jobs |

| Whiteside | USA | Downcut and V-bits | Great for engraving and shallow passes |

| Onsrud | USA | High-end precision bits | I use them for critical edge-quality jobs |

| Sienci Labs | Canada | Hobbyist-grade bits | Good for smaller desktop CNCs |

Investing in good bits pays off. I learned early that cheap tools ruin good material—and when you’re working with plastic laminate, one chip-out can ruin a $70 panel.

FAQ

Here’s a list of the most common questions I get from clients, shop assistants, and new CNC users about working with plastic laminate.

🔍 General Process

- Can all plastic laminates be CNC machined?

→ Most can, but thin PVC laminates are more prone to melting. Use lower speeds. - What type of CNC machine is best for cutting plastic laminate?

→ A full-size CNC router with variable spindle speed and vacuum table is ideal. - Is laser cutting plastic laminate safe?

→ Not usually. Most laminates release harmful fumes and can catch fire under laser heat. - What are the most common problems during machining?

→ Melting, delamination, chipping, and edge burn.

🔧 Tooling & Speeds

- What bit is best for cutting laminate without chipping?

→ Compression bits are best—they cut top and bottom cleanly. - How can I avoid melting during CNC machining?

→ Lower spindle speed, use sharp bits, and ensure good chip evacuation. - How often should I replace router bits for laminate?

→ Every 25–30 sheets or when edge quality starts degrading. - Should I use upcut or downcut bits?

→ Upcut removes chips better, but downcut protects surface. Compression does both. - Do I need cooling or misting systems?

→ Optional, but air blast helps. For PVC laminate, misting can prevent melting.

🛠️ Setup & Finishing

- How do I clamp plastic laminate sheets without damage?

→ Use vacuum tables or soft clamps with spoilboards. - What feed rate and RPM work best?

→ Varies by material, but ~10,000–14,000 RPM and moderate feed rates (~2500–3000 mm/min) are good starting points. - Can I cut laminated particleboard with the same settings as MDF?

→ No. It’s more brittle. You need to reduce pass depth and adjust feed. - How do I get smooth edges after cutting?

→ Use hand files, sanding blocks, or apply edge banding for a clean finish. - Is it possible to engrave into laminate with CNC?

→ Yes! Use a V-bit and shallow paths. Works well on dark surfaces. - What should I do if I see top layer peeling mid-cut?

→ Stop immediately. Check for dull bits or excessive vibration. Reduce feed rate.

🧼 Clean-Up and Waste

- Is laminate dust harmful?

→ It can be. Use dust collection and wear a mask, especially when cutting melamine or phenolic cores. - How do I dispose of plastic laminate waste?

→ Most scraps are non-recyclable. Reuse offcuts, and follow local waste rules. - Can I reuse leftover cut pieces in other projects?

→ Absolutely. I save all usable scraps for jig making or test cuts. - What’s the best way to clean residue from cut surfaces?

→ Isopropyl alcohol or citrus-based adhesive remover. - How do I prevent burning in inside corners or holes?

→ Use a smaller tool for inside radii, and slow down your feed rate in tight paths.

Final Thoughts

I’ve made every mistake possible when machining plastic laminate—burned panels, chipped corners, full-sheet failures. But with patience, the right setup, and a deep respect for how the material behaves, you can get consistently clean results.

The most important lesson I’ve learned? Respect the material. Plastic laminate may seem like just a coated board, but it demands precision, care, and experience to get right.

If you’re getting into CNC fabrication with laminate—or trying to get better at it—I hope this guide saves you time, money, and frustration. Feel free to bookmark it, or share it with your crew. We’re all learning every day.

Authoritative References for Further Reading

- Occupational Safety and Health Administration (OSHA): Machine Guarding for Plastics MachineryOSHA provides comprehensive guidelines on safety measures for operating plastics machinery, emphasizing the importance of machine guarding to protect workers from potential hazards.🔗 https://www.osha.gov/etools/machine-guarding/plastics-machinery

- Atlas Fibre: Essentials of Plastics MachiningThis guide offers in-depth insights into the materials, techniques, and compliance considerations essential for effective plastics machining, including CNC processes.🔗 https://www.atlasfibre.com/plastics-machining-essentials-your-guide-to-materials-techniques-and-compliance/

- National Institute of Standards and Technology (NIST): Mechanical Properties of Laminated PlasticsThis research paper presents data on the mechanical properties of laminated plastics at various temperatures, offering valuable information for understanding material behavior under different conditions.🔗 https://nvlpubs.nist.gov/nistpubs/jres/43/jresv43n3p257_A1b.pdf

- Composite Panel Association: High-Pressure Laminate (HPL) OverviewThe CPA provides an overview of HPL, discussing its durability, applications, and performance properties, which are crucial for selecting the right laminate for specific projects.🔗 https://www.compositepanel.org/products/decorative-surfaces/high-pressure-laminates/

- Wikipedia: Decorative LaminateThis article offers a general overview of decorative laminates, including their composition, types, and applications, serving as a starting point for those new to the subject.🔗 https://en.wikipedia.org/wiki/Decorative_laminate

Other Articles You Might Enjoy

- How Urethane is Machined in Modern Manufacturing: Tips, Tools, and Real-World Use Cases

Introduction I’ve been fascinated by the way Urethane shapes modern manufacturing ever since I first encountered this material in a small prototyping workshop. It was early in my career, and…

- How to Cut, Drill, and Modify ABS Pipe Using CNC Machines

Introduction ABS pipe is everywhere—from plumbing systems to DIY projects, from prototypes to structural parts in lightweight assemblies. But recently, I’ve noticed a growing trend: people want to take their…

- HDPE Machining Guide: Material Properties, Techniques and Applications

Introduction to HDPE and CNC Machining I remember the first time I encountered HDPE. I was working on a small project that required a lightweight, food-safe, and chemically resistant plastic. A…

- Everything You Need to Know About PMMA Material for CNC Machining

Introduction When working in CNC machining, selecting the right material can make or break a project. One material I’ve come to appreciate over the years is PMMA material—better known as acrylic…

- Understanding the Different Types of Plastic for CNC Machining

Title: Understanding the Different Types of Plastic for CNC Machining Introduction CNC machining, a revered and precise manufacturing process, is not limited to metals and alloys. Plastics, with their versatile…

- Plastic CNC Machining Services with PEEK for Complex Components

Introduction to Plastic CNC Machining Services with PEEK The field of manufacturing has embraced the revolutionizing technology of Computer Numerical Control (CNC) machining, taking plastic component production to advanced levels.…

- Navigating the World of Non-Metal CNC Machining: Wood vs. Plastic Material Insights

Introduction to CNC Machining: Special Focus on Wood and Plastic Materials CNC machining, or Computer Numerical Control machining, is a manufacturing process wherein pre-programmed computer software controls the movement of…

- Mastering the Art of Plastic CNC Machining: A Comprehensive Guide

Plastic CNC machining is a precise and versatile manufacturing process that utilizes computer numerical control (CNC) machines to shape and create intricate cnc machined plastic components. This method combines the…