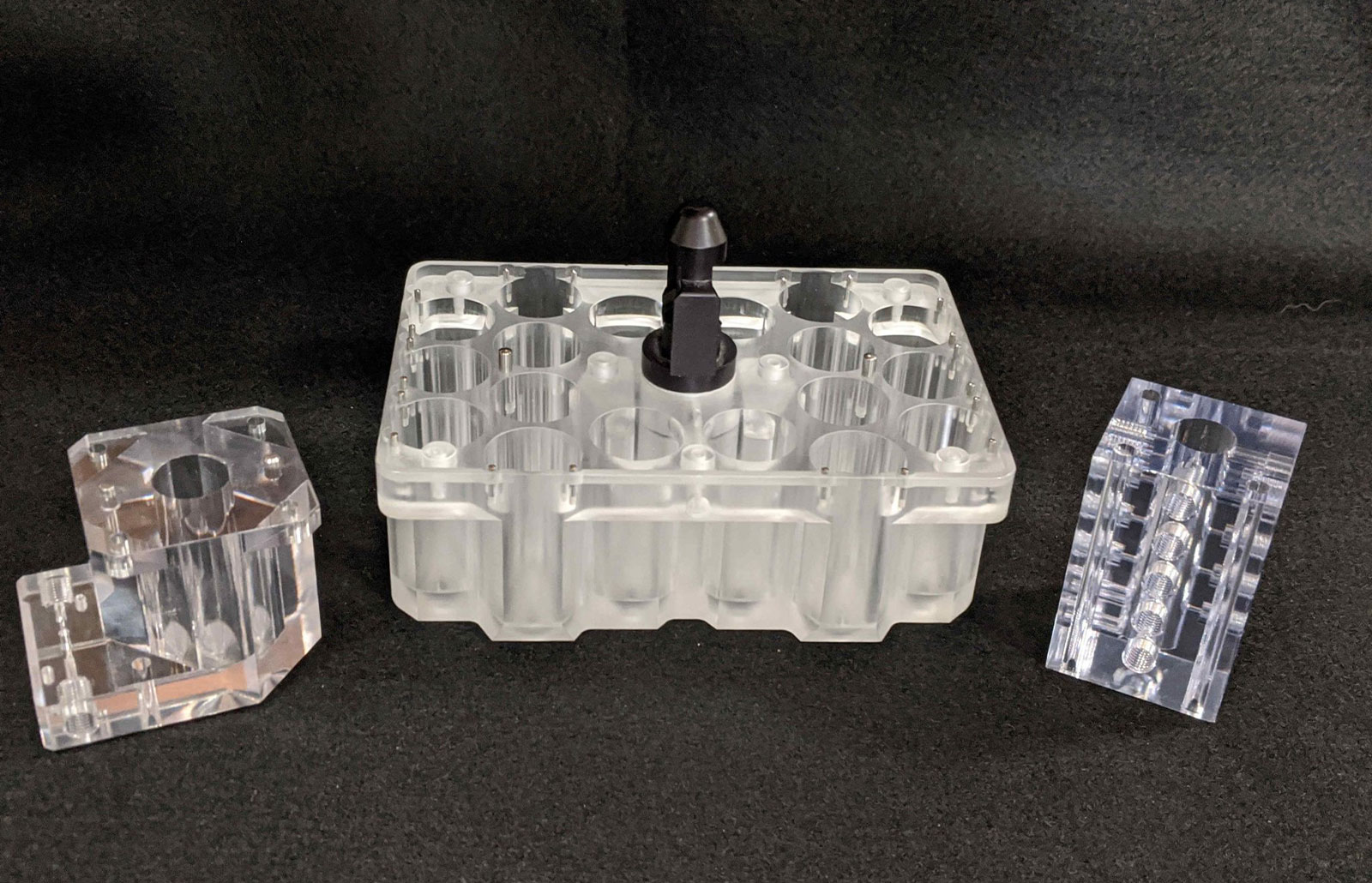

Plastic CNC machining is a precise and versatile manufacturing process that utilizes computer numerical control (CNC) machines to shape and create intricate cnc machined plastic components. This method combines the accuracy and efficiency of CNC technology with the ability to work with various plastic materials.

CNC machines follow pre-programmed instructions to remove material from a plastic workpiece, resulting in highly precise and repeatable outcomes. The process involves using specialized tools, such as mills, lathes, and drills, to carve, cut, or shape plastic parts according to specified designs and dimensions.

Plastic CNC machining (including plastic milling and turning) plays a vital role in numerous industries and applications. Its importance stems from the demand for intricate plastic components with high precision, whether for prototyping or production purposes.

This manufacturing technique finds extensive use in industries such as automotive, aerospace, electronics, medical devices, consumer goods, and many others. CNC Plastic machining enables the creation of complex geometries, intricate features, and tight tolerances, fulfilling the requirements of various industries.

Understanding the Basics of CNC Machining

CNC machining, short for Computerized Numerical Control machining, is a manufacturing process that utilizes computerized control systems to operate machine tools. It involves the precise removal of material from a workpiece to create a desired shape or part. CNC machining enables the automation of various machining operations, allowing for efficient and accurate production.

Components of a CNC Machine

A CNC machine consists of several key components that work together to carry out machining operations:

- Control Unit: The control unit serves as the brain of the CNC machine. It houses the computer and software responsible for programming and executing machining instructions. It interprets the design specifications and generates the necessary commands for the machine.

- Machine Tool: The machine tool refers to the physical equipment that performs the cutting, shaping, or drilling operations. It includes various tools such as mills, lathes, routers, or grinders, depending on the specific machining requirements.

- Axes and Motors: CNC machines typically have multiple axes, which represent the directions of movement along which the cutting tool or workpiece can be positioned. Each axis is controlled by a motor that enables precise movement in the desired direction.

- Tooling: Tooling refers to the cutting tools, such as end mills, drills, or inserts, used in the machining process. These tools are selected based on the material being machined and the desired operation.

- Workholding Devices: Workholding devices secure the workpiece in place during machining. Examples include vises, chucks, clamps, or fixtures. These devices ensure stability and precision during the machining process.

Materials Used in Plastic CNC Milling & Turning

CNC Plastic machining offers a wide range of options when it comes to material selection. Some common plastic materials used in CNC machining include:

Acrylic (PMMA)

Acrylic is a transparent thermoplastic materials known for its excellent optical clarity and weather resistance. It is often used for applications requiring high transparency or impact resistance.

Nylon (Polyamide)

Nylon is a versatile thermoplastic known for its strength, toughness, and resistance to abrasion. It is a popular material when it comes to machining plastic, commonly used in applications that require durability and low friction, such as gears or bearings.

Polyethylene (PE)

Polyethylene is a lightweight thermoplastic known for its excellent chemical resistance and low moisture absorption. Suitable for various applications, including packaging, automotive, and electrical.

Polypropylene (PP)

Polypropylene is a durable plastic and versatile thermoplastic with good chemical resistance and high fatigue resistance. It finds applications in packaging, automotive parts, and consumer products.

Polyvinyl Chloride (PVC)

PVC is a widely used thermoplastic known for its excellent electrical insulation properties. It is commonly used in pipes, fittings, cables, and construction materials.

Polycarbonate (PC)

Polycarbonate is a durable thermoplastic known for its high impact resistance and transparency. It is used in applications such as safety glasses, automotive components, and electronic housings.

Polyethylene Terephthalate (PET)

PET is a thermoplastic commonly used for its excellent dimensional stability, chemical resistance, and transparency. It is widely used in the production of bottles, containers, and packaging materials.

Considerations for Material Selection

When selecting a material for CNC machined plastic parts, several factors should be considered:

Application Requirements

Consider the specific functional and aesthetic requirements of the part, including strength, flexibility, chemical resistance, UV resistance, transparency, or conductivity.

Machinability

Different plastics have varying machinability characteristics, such as their ability to be cut, drilled, or milled. Consider the ease of machining and the complexity of the part’s design.

Cost

Evaluate the cost-effectiveness of the material for your project, considering factors like material availability, waste generation, and tooling requirements.

Post-Machining Processes

Certain plastics may require additional post-machining processes, such as annealing, polishing, or coating, based on the desired final result. Consider the compatibility of the material with these processes.

CNC Machining Techniques for Plastic

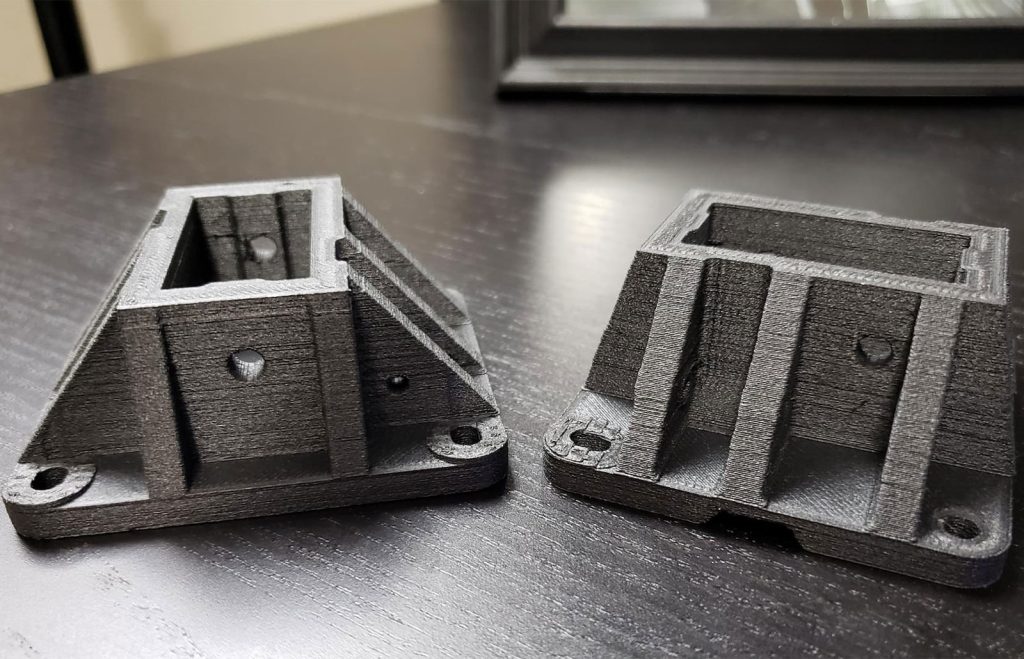

CNC machining offers a variety of techniques for shaping plastic materials with precision and accuracy. Let’s explore some of the common techniques used in plastic CNC machining:

CNC Milling

- Face Milling: Face CNC milling involves removing material from the flat surface of a workpiece. It creates a smooth and even surface by using a face milling cutter. This technique is commonly used for achieving flatness and parallelism on plastic components.

- Profile Milling: Profile milling involves cutting complex shapes and contours on the sides of a workpiece. It utilizes specialized end mills or profile cutters to accurately reproduce intricate profiles, slots, or grooves on the plastic material.

- Pocketing: Pocketing is the process of removing material from within a defined boundary to create pockets or cavities in the workpiece. It involves using end mills or ball nose cutters to cut out specific areas, allowing for the creation of recesses or internal features in plastic parts.

CNC Turning

- Facing: Facing is a turning operation that creates a flat surface at the end of a workpiece. It involves removing material from the outer diameter of the rotating workpiece to achieve a smooth, flat, and perpendicular surface.

- External and Internal Turning: External turning is the process of removing material from the outer surface of a workpiece to achieve the desired shape and diameter. Internal turning, on the other hand, involves machining the inner diameter of a workpiece using specialized tools, such as boring bars, to create holes or cylindrical features.

- Threading: Threading is the process of creating external or internal threads on a plastic component. It involves using thread-cutting tools, such as taps or thread mills, to accurately cut threads that match the desired specifications.

Drilling and Tapping

Drilling and tapping are common operations in plastic CNC machining:

- Drilling: Drilling creates holes of various diameters and depths in plastic materials using drill bits. CNC machines can accurately position the drill bit to create precise holes, whether for fasteners, alignment, or other purposes.

- Tapping: Tapping is the process of creating internal threads in a drilled hole. It involves using a tap tool to cut threads that match the desired specifications, allowing for the insertion of screws or bolts into the plastic part.

Surface Finish

Surface finishing techniques are employed to enhance the appearance, texture, or functional properties of plastic parts. Some common surface finishing techniques in plastic CNC machining include:

- Sanding and Polishing: Sanding and polishing are used to achieve smooth and glossy surfaces on plastic components. Abrasive materials and polishing compounds are applied to remove imperfections and create a refined finish.

- Deburring: Deburring involves removing sharp edges, burrs, or excess material left after the machining process. It ensures the part’s safety, improves aesthetics, and facilitates assembly.

- Surface Texturing: Surface texturing techniques, such as etching or engraving, can be employed to create patterns, logos, or textures on plastic surfaces, adding visual appeal or enhancing grip.

By employing these CNC machining techniques, precise and complex shapes can be achieved on plastic materials.

Main Takeaway

Plastic CNC machining is a powerful tool in the realm of manufacturing, enabling the realization of intricate designs, precise dimensions, and functional plastic components. By leveraging the knowledge and techniques shared in this guide, you can embark on your journey to master the art of plastic CNC machining and unlock the full potential of this versatile manufacturing process.

If you’re looking for a convenient and affordable way to bring your plastic CNC machining projects to life, look no further than Want.Net. As an online CNC machining service, we offer professional and reliable manufacturing solutions at competitive prices. Our team of experienced machinists and state-of-the-art equipment ensure top-quality results for your plastic machining needs.

Related Posts

- Nickel vs. Cobalt Alloys in High-Temperature CNC Machining: A Detailed Analysis?

Nickel and Cobalt Alloys in High-Temperature CNC Machining Both Nickel and Cobalt alloys play an essential role in high-temperature CNC machining. These metal alloys are popular choices due to their…

- 5-Axis CNC Machining of Steel Components: Efficiency and Precision

Introduction to 5-Axis CNC Machining Cementing itself on the technological forefront, computer numerical control (CNC) machining is a manufacturing process that utilizes computerized controls to manoeuvre factory machines and tools.…

- Aluminum CNC Machining Services: Precision and Custom Solutions

Introduction to Aluminum CNC Machining Services In the world of manufacturing, Aluminum CNC machining services stand as a vital solution. Utilizing computer numerical control (CNC) technology, these high-precision services employ…