Introduction to CNC Machining and Material Selection

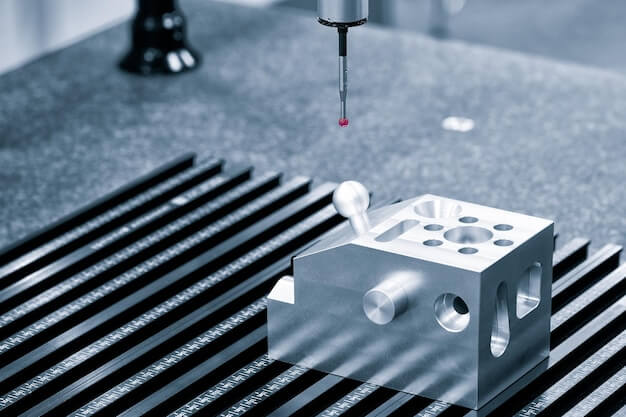

Computer Numerical Control (CNC) machining is a vital manufacturing process that uses programmed software controls to dictate the movement of factory machinery and tools. This precision-focused technique enables complex shapes and designs to be created in a range of materials, offering efficiency as well as high repeatability. But an essential aspect of this method lies within selecting the right material for part construction. Two such materials gaining prominence due to their unique characteristics are Zirconium and Titanium.

- Zirconium exhibits excellent corrosion resistance, heat resistance, and enhanced mechanical properties – all being fundamental features for industries like aerospace, medical equipment, and chemical processing.

- Titanium on the other hand is famed for its exceptional strength-to-weight ratio, biocompatibility, and its ability to withstand extreme temperatures. These characteristics make it invaluable in sectors such as medical implants, marine applications, aircraft design, etc.

The choice between these two materials largely depends on distinct project requirements including costs, structural integrity, longevity, compliance standards, and more. Thus, understanding each material’s capabilities becomes critical in determining the success of any CNC machined component.

Understanding Zirconium in CNC Machining

Zirconium is a material often employed within the realm of CNC machining, favored for its unique properties that enhance the manufacturing process. As a high strength metal, zirconium exhibits remarkable durability, able to sustain excessive wear and tear without detrimental effects on structural integrity or performance. It features excellent chemical resistance as well, thereby allowing it to function optimally even when exposed to corrosive substances.

- Strength: The inherent strength of zirconium allows parts machined from this metal to withstand heavy loads, impacts, and stress factors without deforming or breaking.

- Durability: Due to its noble nature, zirconium does not corrode easily, which significantly extends the lifespan of zirconium-based components compared with parts composed of less resistant materials.

However, one must also consider the cost implications when selecting zirconium for CNC machining. While offering superior characteristics, zirconium generally incurs a higher initial investment than some other, more common metals such as stainless steel or aluminium due to its scarcity and complex extraction processes. Nevertheless, given its long-term reliability and low maintenance requirements, the overall lifecycle costs may still prove economical despite the upfront expenses.

Understanding Titanium in CNC Machining

Titanium is one of the widely utilized materials in CNC machining. This material’s popularity is largely due to its outstanding properties that are favorable for manufacturing scenarios, such as being highly resistant to corrosion and substantial durability.

- Overview: As a metallic element, titanium features high strength-to-weight ratio making it crucial in aerospace applications where weight matters without compromising strength and durability.

- Properties: Among significant properties of titanium include formidable resistance to corrosion, even under severe conditions where most metals will succumb quickly. Furthermore, titanium can withstand high temperatures while maintaining substantial mechanical properties.

- Costs: Associated costs with utilizing titanium in CNC production could be relatively higher due to factors like tooling wear or slower feed rates needed due to its toughness. However, these could be offset by the longevity and reliable performance yielded in the finished products.

Comparative Analysis: Zirconium vs Titanium in CNC Machining

When comparing zirconium and titanium in CNC machining, it’s important to consider their unique properties and applications. Zirconium offers advantages such as mechanical strength, chemical stability, biocompatibility, good aesthetics, and better wear resistance, making it suitable for dental and metallic implants. On the other hand, titanium alloys have exceptional strength-to-weight ratios, corrosion resistance, good heat conductivity, and biocompatibility, making them suitable for aerospace, military, and biomedical applications. For precision CNC machining needs, consider Precision Machining Service to ensure top-notch quality and accuracy.

Conclusion: Key Differences and Selection Advice for Zirconium vs Titanium in CNC Machining

In CNC machining, both zirconium and titanium exhibit exceptional qualities giving them special places in diverse industries. Nevertheless, they present unique differences that dictate their suitability in various applications. Titanium stands out with higher strength-to-weight ration, excellent resistance to corrosion, good tolerance under extreme temperatures, lightweight nature, and high biocompatibility hence its vast use where maximum strength but minimum weight is desired, like the aerospace industry.

Zirconium on the other hand boasts impeccable resistance to heat, wear, highly reactive chemicals making it ideal for nuclear reactors, specialty alloys, among other uses.

- Titanium’s ample supply overshadows zirconium’s rarity making it more affordable between the two.

- The choice between using either of these materials largely depends on the type, conditions and priorities of a given application- value for money, product quality or combination of both.

- If you want high-quality products without considering budget constraints, go for zirconium.

- Rather if your aim is cost-effectiveness without compromising too much on performance, then titanium would be optimal.

Consider consulting an expert before settling on either material due to the high-tech and nuanced decisions entailed.

Frequently Asked Questions about Zirconium vs Titanium in CNC Machining

In the context of CNC machining, it’s common for users to have queries regarding the selection between Zirconium and Titanium. One fundamental question is often related to cost-effectiveness. Generally speaking, while Titanium may present an initially higher cost due to its superior strength and corrosion resistance, its long service life typically translates into overall reduced costs over time. On the other hand, Zirconium offers similar capabilities at a potentially lower immediate expense.

Another commonly asked question pertains to heat resistance, a critical factor in many applications. While both materials perform well under high temperatures, titanium might offer slightly better performance, justifying its use in more demanding environments. In simpler applications where moderate heat resistance suffices, zirconium can be considered as a viable, less costly alternative.

- Titanium: Higher initial cost, superior strength, good for demanding environments.

- Zirconium: Lower immediate cost, adequate capabilities, suitable for less intensive applications.

The choice between these two materials should ultimately hinge on evaluating their respective benefits against the specific requirements of your project, keeping in mind that while upfront costs are crucial, they don’t always reflect the long-term values of these materials.

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Breaking Barriers in CNC Machined Aerospace Structures

Introduction: CNC Machining in Aerospace Structures In the aerospace industry, accuracy, reliability and efficiency are paramount. To maintain these standards, modern day aerospace manufacturing heavily leans on Computer Numerical Control…