CNC, or Computer Numerical Control machining is a widely used manufacturing process that utilizes computerized controls to operate and manipulate various types of machinery such as mills, lathes, routers, grinders, and more. This technology has revolutionized the manufacturing sector through automated precision, consistency, and superior quality work while ensuring time and cost efficiency. One aspect significant to enhancing CNC machining’s finish comes from a process known as bead blasting.

Bead blasting is an essential finishing technique in not only the manufacturing realm but specifically within the sphere of CNC machining as well. It applies tiny glass beads onto the surface of a material under high pressure without causing any damage. The main aim here is to enhance the finished look by creating a smoother, cleaner, and brighter appearance. Bead blasting also helps remove contaminants on surfaces and contribute to their durability.

So what makes bead blasting special in connection with CNC machining? Let’s delve deeper into this fascinating world where technology meets meticulous finesse.

Producing a product using both CNC machining and bead blasting requires several steps:

1. Designing Stage

It starts with designing the product optimally using CAD (Computer-Aided Design) software. Accuracy at this stage ensures proper function and longevity of the manufactured component.

2. Programming the Machine

The design then gets converted into a program that dictates the operations of the CNC machine, mainly its precise movements during production. These detailed instructions minimize errors leading to higher productivity.

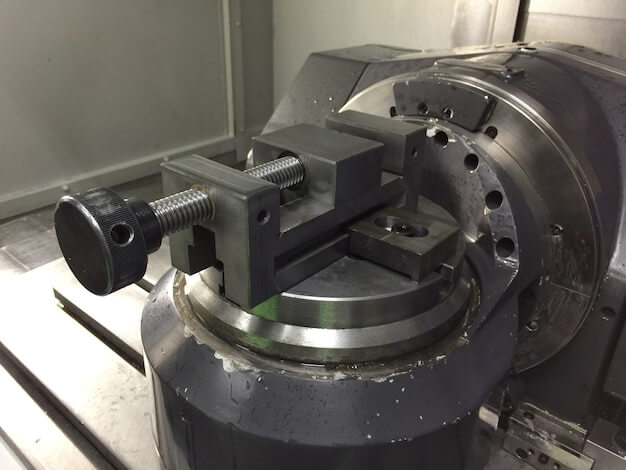

3. Machining Process

This phase involves using the CNC machine to create the desired part from raw material. Its high speed and accuracy produce intricate designs consistently with minimal waste.

4. Checking Quality

Quality checks are quintessential before moving forward. Inspection for any defects ensures that the product adheres to set specifications and standards.

5. Bead Blasting

After confirming the quality, it undergoes the bead blasting process. The surface gets cleaned, enabling it to stand wear and tear, extending the component’s lifespan.

The process of bead blasting in CNC machining has some incredible benefits:

– Enhanced Appearance: Bead blasting adds an aesthetic value by giving a uniform matte finish which looks better than a typical rugged machined component.

– Better Durability: It helps eliminate metal impurities and reduce corrosive damage, aiding to increased part longevity.

– Improved Precision: Removing burrs or other machining imperfections can enhance functional performance.

However, everything comes with its challenges. In bead blasting, too heavy-handed use can distort delicate features of a material. Therefore, optimizing pressures used for different materials is crucial.

No matter how advanced technology becomes, the requirement for skilled human hands remains irreplaceable. Proper training is paramount in handling both the CNC machines and bead blasting equipment for safe and effective use.

In conclusion, bead blasting plays a significant role in enhancing each piece produced through CNC machining. This synergy between precision-oriented CNC machinery and the careful finesse offered by bead blasting results in productions that far supersede standard manufacturing quality. Whether you are entering this industry as a professional or business person seeking the best product outcomes, understanding these processes eliminates guesswork and drives success. So, delve into the exciting blend of technology and art today!

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Innovative CNC Machining for Advanced Sporting Goods

Innovative CNC Machining for Advanced Sporting Goods CNC machining, or Computer Numerical Control machining, is a high-precision manufacturing process where pre-programmed computer software dictates the movement of factory machinery and…

- Custom CNC Machining Solutions for Brass and Stainless Steel

Introduction to Custom CNC Machining Solutions for Brass and Stainless Steel Custom CNC (Computer Numerical Control) machining is a manufacturing process that involves programmed codes directing the movement of factory…