Detailed Explanation of Surface Quality in Machining

Surface quality in machining not only affects the appearance of the product but also has a significant impact on its

Surface quality in machining not only affects the appearance of the product but also has a significant impact on its

In the field of machining, the quality of parts is fundamental to ensuring the performance and longevity of mechanical products.

In the world of metal surface finishes, chemical coloring has gained significant traction, especially for aluminum and copper. This technique

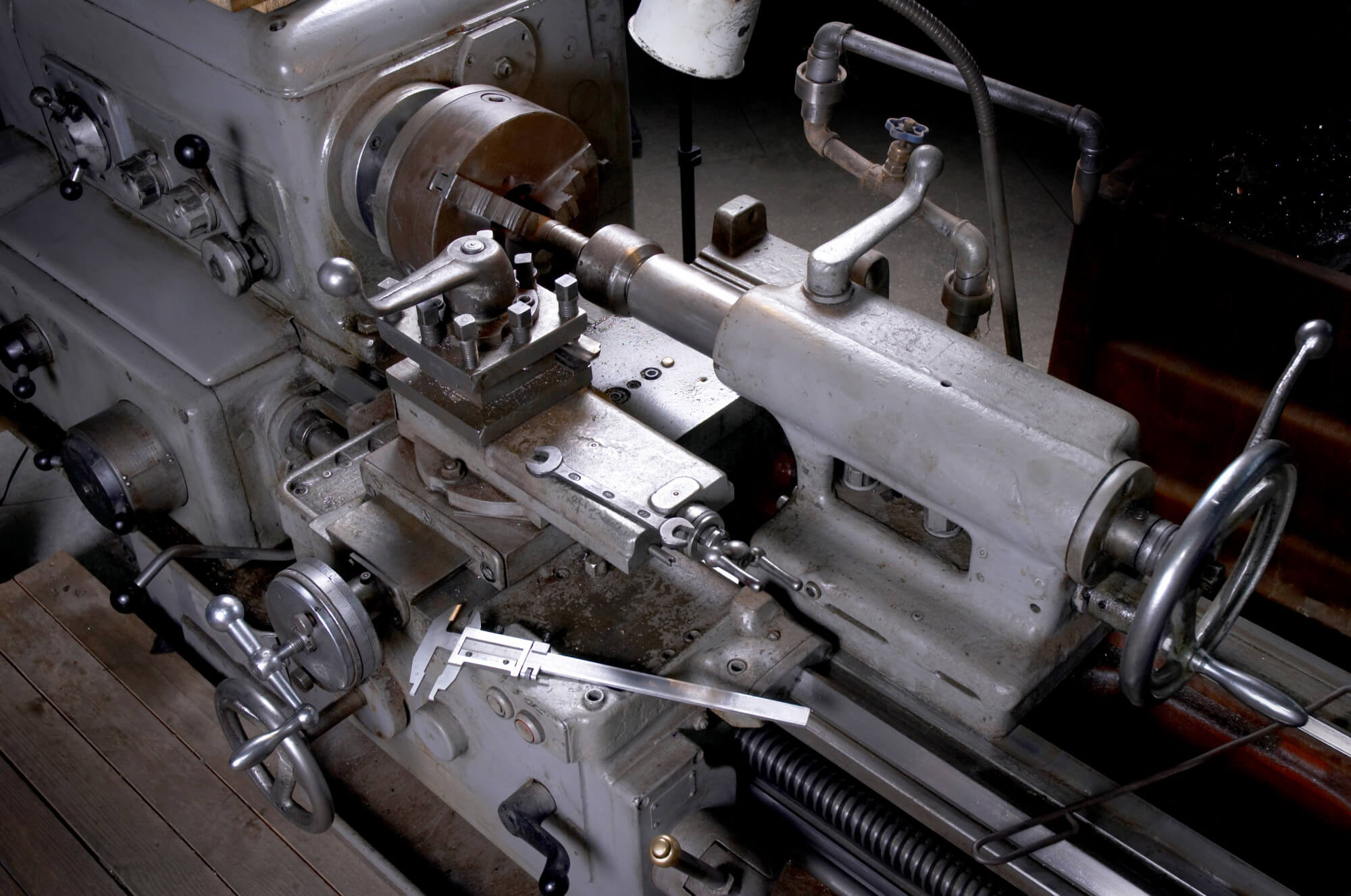

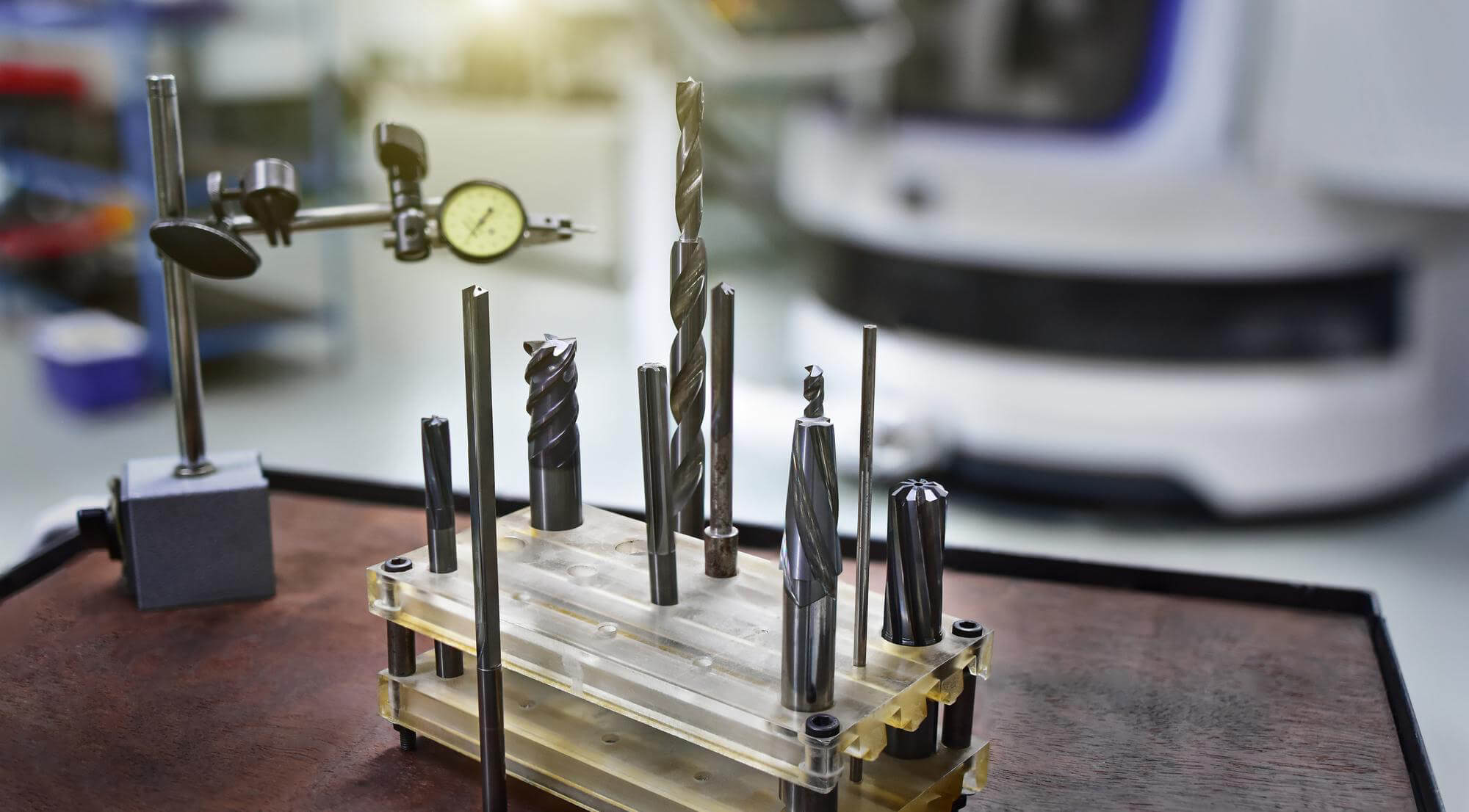

In every machine shop, Often, after CNC drilling is complete, it is necessary to enlarging holes.There are three common methods

Selection of Blank Forming Methods and Machining Processability In the process of mechanical manufacturing, selecting appropriate blank forming methods and

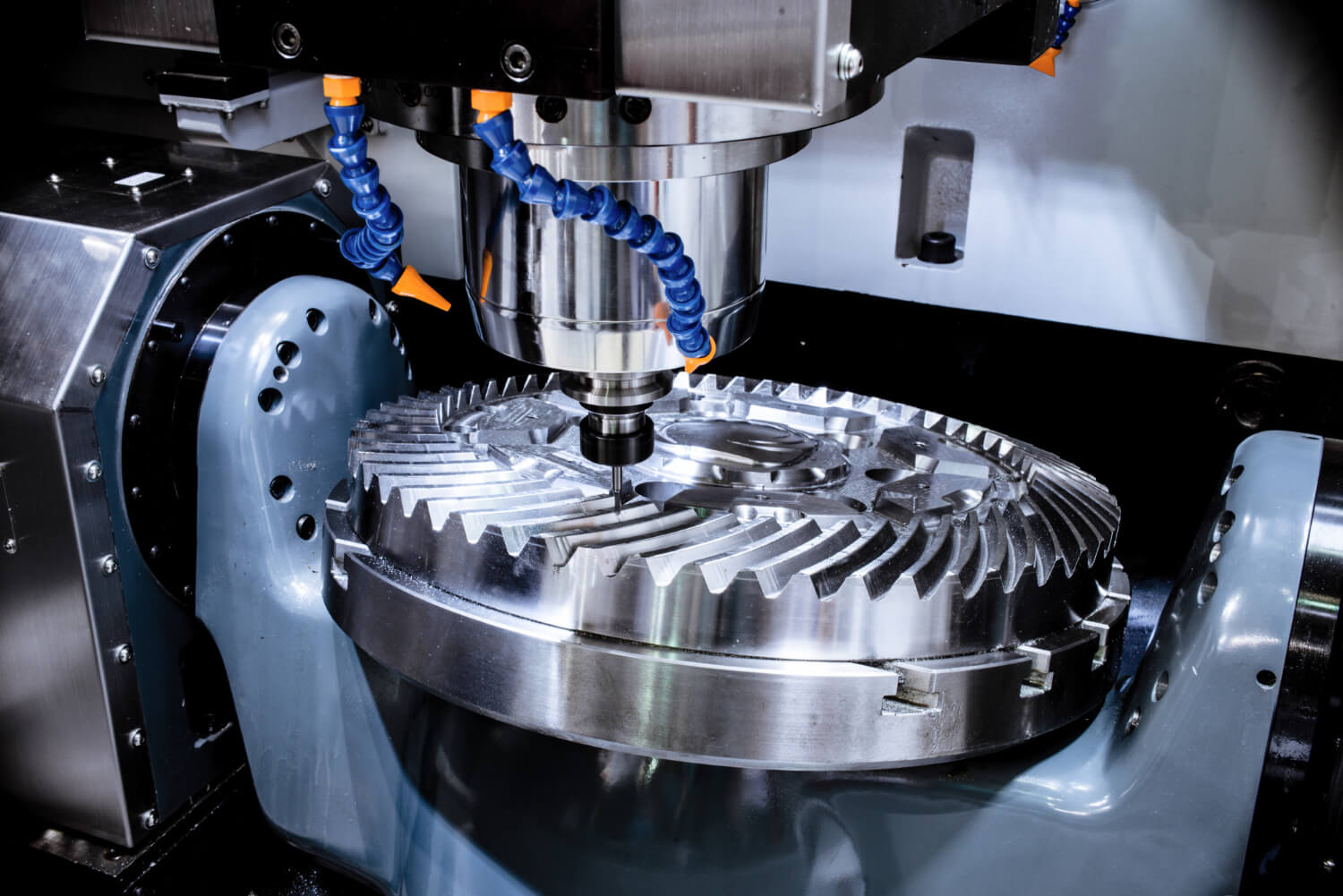

In the world of mold and aerospace machining, two-dimensional cavity machining stands out as one of the most material-intensive and

In mechanical manufacturing, selecting and forming blanks are critical factors that influence product quality, cost, and performance. Choosing the right

Many metals naturally form a protective oxide film on their surfaces, a process known as passivation. Chemical conversion films take

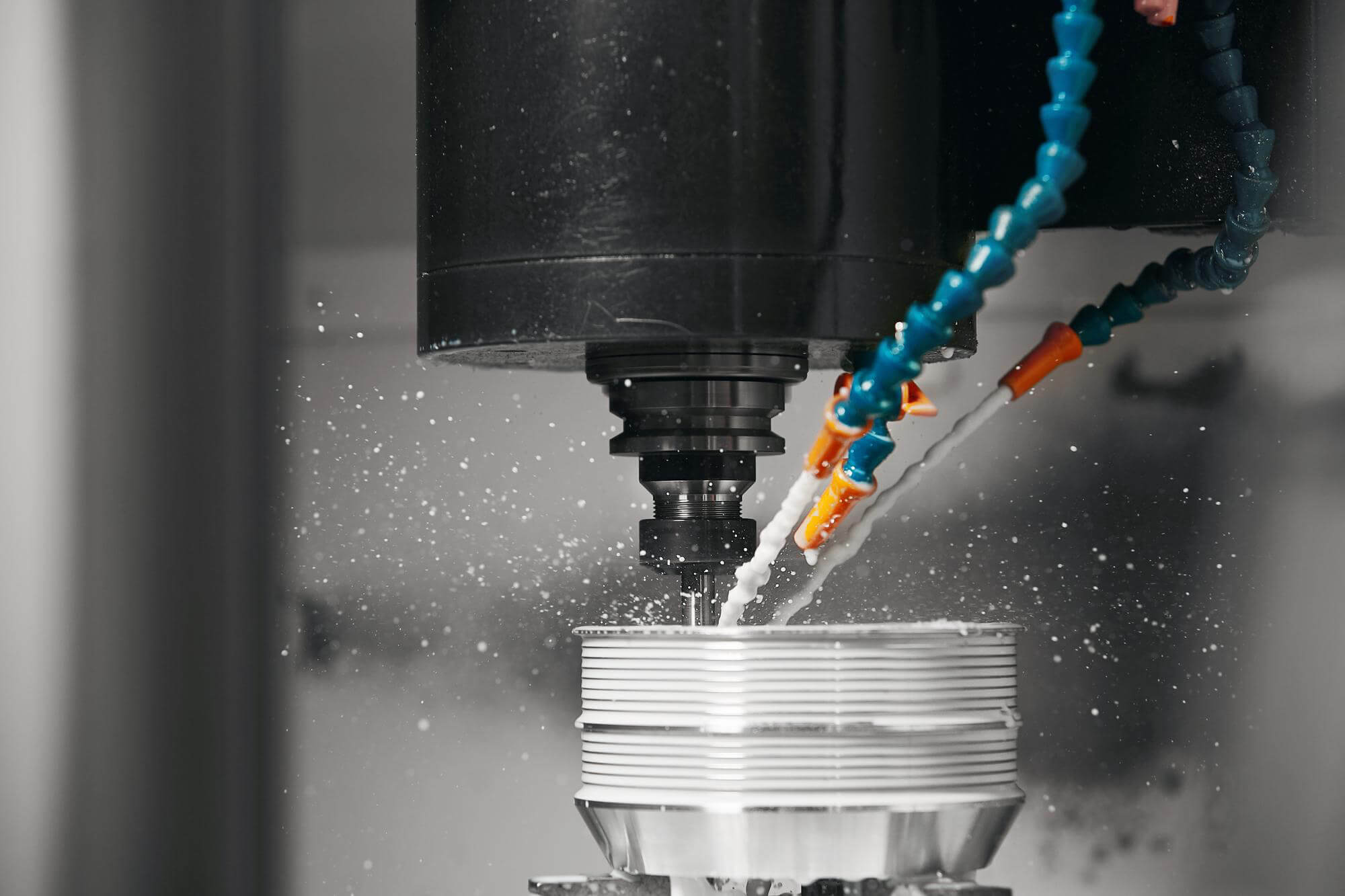

High-speed cutting (HSM or HSC) is not just a technological advancement; it’s a fascinating journey of innovation that has transformed

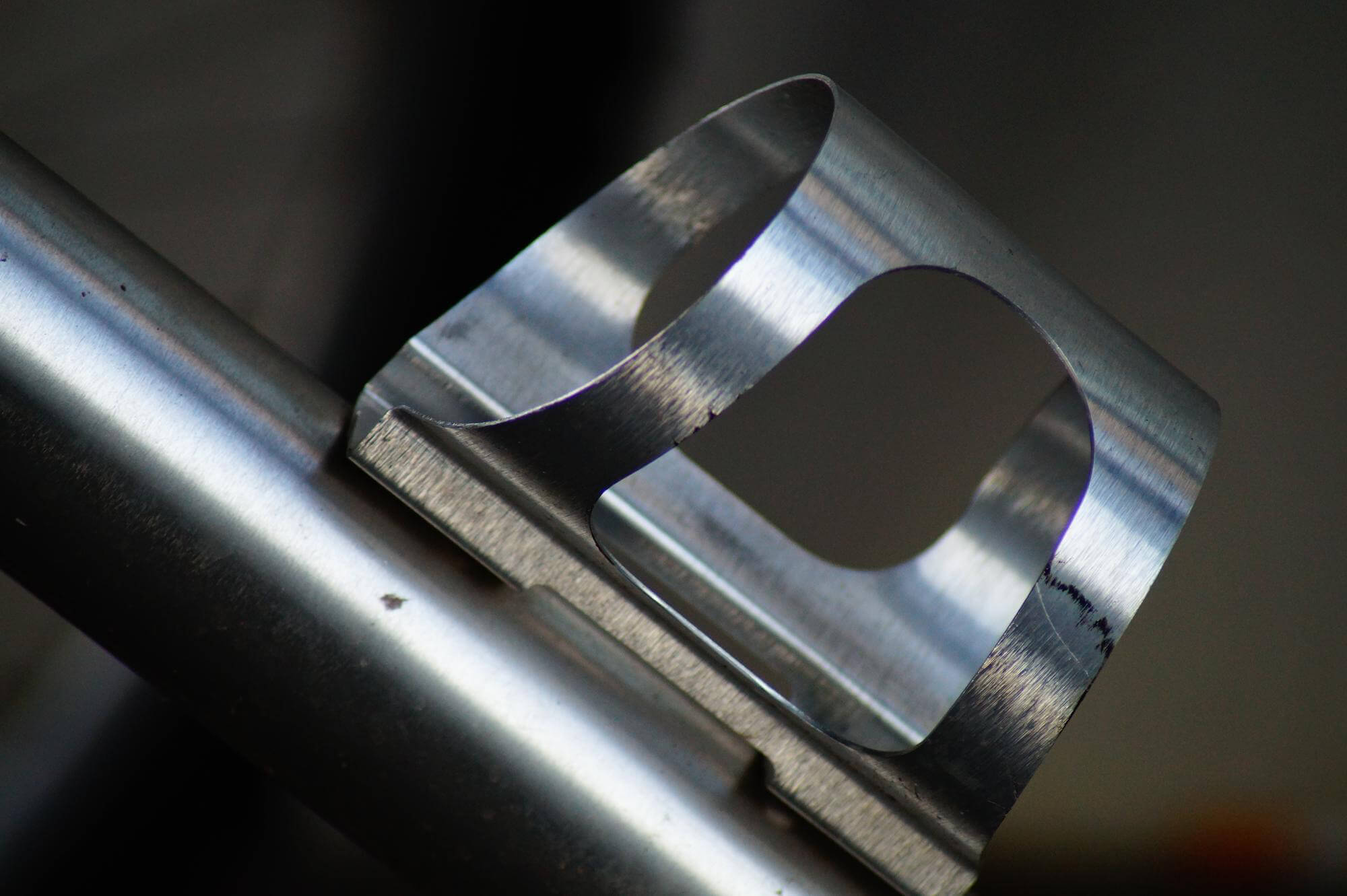

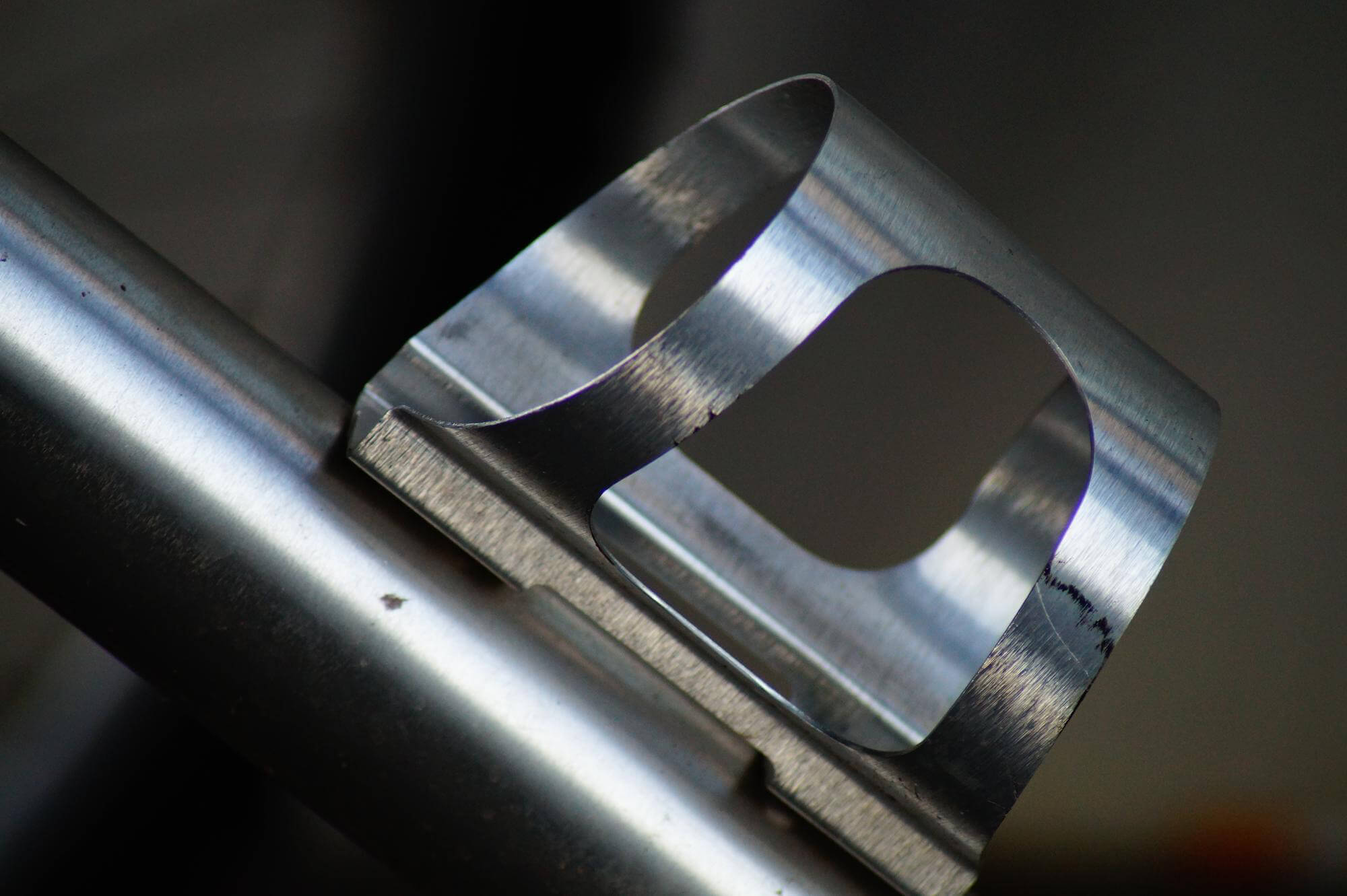

Boring holes with precision and quality in CNC machining can be a bit tricky, but with the right techniques, it

The Basics of CNC Turning-Milling Compound Machining Programming The programming basics for CNC turning-milling compound machining can vary due to

Surface quality in machining refers to the overall condition of a part’s surface after machining, encompassing its geometric shape, physical-mechanical

You’re one step from the factory-direct price of part manufacturing services.