In every machine shop, Often, after CNC drilling is complete, it is necessary to enlarging holes.There are three common methods for enlarging holes from the top: countersinking, counterboring, and spotfacing. These techniques are crucial for ensuring that mating parts fit precisely, particularly when bolt heads need to sit flush against a flat surface. Each method requires high concentricity and precise programming, with variations mainly in the tools used and slightly different spindle speeds and feed rates compared to standard drilling.

1. Countersinking

Countersinking involves creating a conical hole to match the head of a countersunk screw or bolt. It’s the most calculation-intensive of the three methods, needing precise depth measurements to ensure the perfect fit. The three most common countersink angles are 60°, 82° (the most typical), and 90°, though other angles are occasionally used.

To illustrate the programming and calculations involved, let’s look at a typical countersinking tool. The dimensions include the body diameter (d), countersink angle (A), drill point diameter (F), and tool length (L). When programming a countersinking operation, certain specifications from the blueprint are crucial. For example, a specification might read “Ø0.78 Countersink – 82°” and “13/32 Drill Through Hole.”

Accurate diameter values are essential and are obtained by carefully calculating the Z-axis depth. This involves constants (K) for different angles, which helps compute the drill tip length and ultimately the cutting depth. Here’s how you calculate it:

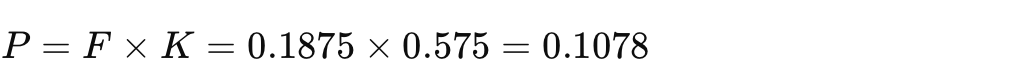

- Determine Height P: Using the given drill point diameter (F) and the constant K for the angle.

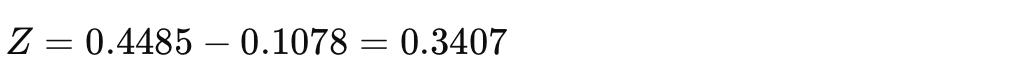

- Calculate Z-axis Depth: Subtract height P from the theoretical Z-axis depth.

For instance, with a countersink angle (A) of 82° and drill point diameter (F) of 3/16 (0.1875):

If F = 0 (sharp point), the Z-depth ignores height P:

Including height P, the final Z-depth becomes:

The resulting program segment might look like this:

N35 G99 G82 X0.75 Y0.625 R0.1 Z-0.3407 P200 F8.02. Counterboring

Counterboring creates a cylindrical hole to accommodate the head of a socket head screw or bolt, ensuring it sits below or flush with the surface. This process is used for rough or uneven surfaces or when the bolt needs to be perpendicular to the surface. Typically, a specialized counterbore tool is used, though an end mill can sometimes substitute. The programming uses the G82 canned cycle, with the known depth making calculations straightforward.

For example, for a through hole with a diameter of 1/2 inch and a counterbore diameter of 0.72 inch with a depth of 0.25 inch:

N41 G99 G82 X.. Y.. R0.1 Z-0.25 P300 F5.0Ensuring the pause time (P) in the G82 cycle is long enough is crucial. For a spindle speed of 600 rpm, the minimum dwell time (Dm) is:

Double this for a more reliable dwell time:

[ P = 0.2 ]

Thus, allowing the spindle to complete at least one full rotation to clean the bottom surface of the hole.

3. Spotfacing

Spotfacing is similar to counterboring but involves removing only a small amount of material to create a flat surface for a bolt head, washer, or nut. It’s often referred to as shallow counterboring. The programming approach is identical to counterboring, with similar tool choices and G82 cycle usage.

Spotfacing requires minimal depth cuts and is used to ensure a smooth mating surface. The main focus is on precision and achieving a perfectly flat surface.

Summary Table

Here’s a summary table of key parameters for these operations:

| Method | Purpose | Typical Tool | Angle (for CSINK) | Depth Calculation |

|---|---|---|---|---|

| Countersinking | Conical hole for countersunk screws | Countersink | 60°, 82°, 90° | Z-depth minus height P |

| Counterboring | Cylindrical hole for socket screws | Counterbore | N/A | Known depth |

| Spotfacing | Flat surface for bolt heads/nuts | End mill | N/A | Known depth |

By mastering these techniques, machinists can ensure that CNC machined parts meet precise specifications and fit perfectly in their assemblies. High concentricity, accurate depth calculations, and appropriate tool selection are crucial for achieving optimal results in countersinking, counterboring, and spotfacing operations.

Other Articles You Might Enjoy

- Requirements for CNC Machining Parts

Preparation Work Complete the necessary preparation before machining, including process analysis, process route design, tool and fixture selection, and program compilation. online cnc machining service Operating Steps and Contents Start…

- What are the requirements for CNC machining of bearing parts?

Bearings are common and important parts in the automotive industry, which can support transmission components and transmit torque. Generally, CNC machining centers are used to process bearing parts. So what…

- The Ultimate Guide to Acquiring CNC Machined Parts

In today's business landscape, there are two main categories: production and services. While service-based businesses are easier to establish, production businesses hold greater potential for growth. If you're considering venturing…

- What should be noted about materials when machining parts with CNC?

When machining parts with CNC, not all materials can be precisely processed. Some materials are too hard and may damage the CNC machining tools, making them unsuitable for precision machining…

- Mastering Corner Control in CNC Machining Parts

CNC machining is all about precision and efficiency, especially when it comes to navigating sharp corners and changing directions. When machining complex contours, the feed rate and movement control are…

- Improve the Precision of Your CNC parts

In some industries, precision machining is more essential than in others. For example, medical devices, certain parts, and products must be reliable and always work. The doctor must direct the…