Custom CNC Machining in the Aerospace and Medical Sectors

In response to the steady growth of both the aerospace and medical industries, increasingly sophisticated manufacturing techniques have become a necessity. Custom Computer Numerical Control (CNC) machining services for titanium parts is one such technique, providing precise, efficient, and reliable solutions that can deal with the inherent challenges these sectors face.

- The aerospace industry necessitates strong but lightweight materials that can withstand extreme temperatures – titanium meets these exacting criteria perfectly.

- On the other hand, the medical sector demands sterile and non-reactive components – again, properties that are intrinsic to titanium.

This mutual requirement has led to the increased usage of custom CNC machining in the production of titanium parts. By using advanced design software coupled with high-speed machining tools, manufacturers can achieve unprecedented levels of precision. This ensures every part, whether an aircraft component or a surgical instrument, meets stringent quality and safety standards.

Basics of Precision Manufacturing with a Focus on Custom CNC Machining

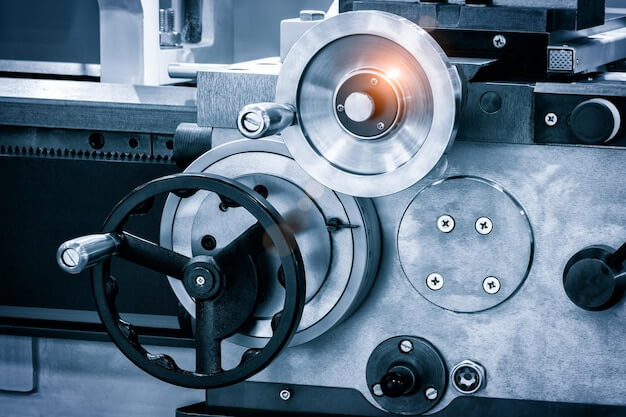

Precision manufacturing is a process where parts are produced by removing specific layers from a workpiece using advanced machine tools to ensure high accuracy and repeatability. This realm of manufacturing has taken immense strides with the advent of Computer Numerical Control (CNC) machining. CNC machining is a subtractive manufacturing technology which utilizes computerized controls to operate and manipulate machine tools, leading to products with intricate details, superior quality, and enhanced durability.

In modern manufacturing, CNC machining has become instrumental due to its ability to meet demanding precision requirements while maintaining consistent production standards. It offers unparalleled flexibility in terms of design versatility, reduced lead times, and effective cost management.

Custom CNC machining takes a crucial role in meeting specific industry needs. Industries such as aerospace and medical have stringent requirements for component accuracy, materials used, and strict compliance norms. Custom CNC machining allows for the creation of tailored solutions that meet these unique specifications, enabling advancements in both industries.

Valuable Characteristics of Titanium

Titanium, widely adopted in the aerospace and medical sectors for its unique properties, has become a metal of choice for multiple industries. Its superior strength, lightweight nature, and corrosion resistance inherently qualify it for an array of critical applications.

- Strength: Titanium’s high material strength makes it ideal for different demanding environments where other metals would falter. For example, aerospace engineers often use titanium to withstand intense pressure and temperature evolutions during flight operations.

- Lightweight: Despite its impressive toughness, titanium is significantly lighter than many common industrial materials like steel or iron. Thus, it ensures optimum performance without sacrificing durability – which is especially vital within aerospace constraints.

- Corrosion Resistance: Titanium sets itself apart with an innate resilience against rusting and erosion. Consequently, it promises longevity under harsh conditions, including those witnessed within healthcare procedures involving bodily fluids or pharmaceutical compounds.

In conclusion, these attributes collaboratively contribute to making titanium an invaluable asset within custom CNC machining services. The enhanced ability to adhere to precise design requirements while offering outstanding functionality substantiates its utilization across key industries.

Role of Custom CNC Machining Services for Titanium Parts in Aerospace Industries

Custom CNC machining services play a crucial role in aerospace industries by providing:

- Precision manufacturing of titanium parts

- Creation of vital components for aircraft engines and structural elements

- Ability to meet the high-quality requirements of the aerospace industry

- Enhancement of aerospace technology and innovation

Contribution of Custom CNC Machining Services for Titanium Parts to Medical Sectors

The application of custom CNC machining services for titanium parts has revolutionized the medical industry by producing high precision equipment and prosthetics that surpass other material choices. In particular, essential tools like surgical instruments and implants rely heavily on CNC-machined titanium parts for their construction.

- Surgical Instruments: Scalpels, forceps and scissors, among other surgical tools, are crafted with intricate detail using custom CNC machining. These implements require utmost precision, accuracy and durability – all provided by titanium materials.

- Aircraft Implants: Utilizing titanium in crafting implants is advantageous because of its light weight, strength and biocompatibility. It’s resistant to corrosion from body fluids which extends implant lifespan, reducing the need for repetitive medical procedures.

An illustrative case study highlights these benefits: patients witnessed improved health outcomes after receiving hip replacements made from CNC-machined titanium compared to those made from traditional metals. Overall, these services substantially contribute to enhanced patient care within the medical sector.

Challenges and Solutions in Custom CNC Machining for Titanium Parts

Custom Computer Numerical Control (CNC) machining of titanium parts does come with its own set of challenges. High cost is often one of the most significant hurdles, primarily due to the exceptional durability and strength of titanium which reduces tool life and thus increases costs. Additional technical difficulties include complex processing requirements, heavy-duty machining equipment needs, and heat generation that may distort the workpiece.

Nevertheless, advancements in technology and efficient operation management are providing valuable solutions. Utilization of cutting-edge machine tools improves operational efficiency and extends tool lifespan, thereby reducing costs. With advanced cooling technologies, dissipation of excess heat generated during machining can be managed to prevent part distortion.

- High Costs: The use of high-grade titanium often leads to increased expenses due to its impact on tool life. However, implementing high-performance cutting tools can counteract this issue by enhancing tool longevity and improving productivity.

- Technical Difficulties: Complexities related to processing requirements call for sophisticated technology and techniques. Advanced machine tools capable of handling intricate tasks offer a viable solution.

- Heat Generation: Overheating during machining could lead to deformation of the titanium part. This complication can be mitigated through modern cooling mechanisms which efficiently dissipate the heat produced while minimizing potential damages to the workpiece.

Related Posts

- Aluminum CNC Machining Service for Custom Parts

Aluminum CNC machining stands at the forefront of modern manufacturing, epitomizing precision, versatility, and efficiency. With its widespread applications across industries ranging from aerospace to automotive and beyond, aluminum CNC…

- Aerospace CNC Machining: What You Need to Know

At present, the global aerospace industry market value has increased by 278.43 billion, an increase of 6.6% compared to 2022. The ultra-high value proves that innovation in the aerospace industry…

- CNC Machining for Aerospace Applications: Titanium vs. Aluminum Alloys

CNC Machining in Aerospace: An Introduction and Overview Computer Numerical Control (CNC) machining is a manufacturing process that utilizes software-directed machines to fabricate complex parts with high accuracy and repeatability.…

- Nylon CNC Machining Service for Custom Parts

Nylon is an engineering plastic known for its high strength, wear resistance, and chemical inertness. It possesses excellent mechanical properties and durability, making it widely used in various fields including…

- 10 Advantages of CNC Machining for Custom Parts

CNC machining services produce high-quality parts with accuracy and efficient production. These CNC machines use computer numerical control machining tools to cut and shape materials precisely. Additionally, CNC machining services…

- CNC Machining for Aerospace: Titanium Alloys vs. Aluminum - Performance and Cost Analysis

CNC Machining in the Aerospace Industry: An Introduction and Importance of Material Selection CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software directs the movement of…