Relevance and Benefits of Cost Reduction in 3D Printing

In an era where innovation is pivotal, 3D printing emerges as a transformative force across numerous industries, from manufacturing complex aerospace components to creating bespoke medical devices. However, the cost associated with this technology can often be a barrier to entry or expansion. Minimizing expenses in 3D printing not only makes it more accessible but directly translates into competitive pricing, higher profit margins for businesses, and ultimately fuels further innovation by reallocating saved resources. For instance, employing techniques like hollowing out models or optimizing print orientation ensures material efficiency and reduces waste—leading to substantive savings on materials that often comprise a significant portion of the overall cost.

Understanding 3D Printing Costs

The cost-effectiveness of 3D printing hinges upon understanding the various expenses involved in the process. Material expenditure often dominates the conversation, with prices varying significantly based on the type of filament used—PLA is generally economical while specialized composites can be more costly. Machine operation costs cannot be overlooked either; this includes electricity usage and the depreciation of the printer itself over time. Labor costs also come into play, especially for post-processing requirements that demand manual effort to finish a piece. Furthermore, machine maintenance and potential downtimes add to the overall financial picture by affecting production flow and longevity of equipment. Optimizing each of these cost facets ensures a balanced and economically sound 3D printing strategy.

Material Considerations for Cost-Effective 3D Printing

In the context of 3D printing, selecting the right materials is crucial to manage expenses without sacrificing the integrity of the final product. This involves a strategic choice between various types of filaments, resins, or powders, aligning their properties with the intended application’s requirements. For instance, while a project may traditionally use ABS plastic for its strength and heat resistance, employing PLA—a biodegradable thermoplastic derived from renewable resources like cornstarch—can be substantially more cost-efficient for prototypes or non-functional models due to its lower price point and ease of printing. Choosing materials judiciously ensures that quality is upheld where necessary, and costs are trimmed wherever possible.

Design Optimization for Cost Saving

Economizing on 3D printing expenses can largely be attributed to the cunning refinements in design prior to production. One pivotal strategy is the simplification of geometry, which directly influences not only the print time but also curtails material use significantly. By removing unnecessary complexity and streamlining shapes, one ensures a more cost-effective model without sacrificing function. Further cost reductions are realized by integrating hollow features into designs along with decreasing infill percentages where structural integrity remains uncompromised, thus requiring less filament. Efficient design software tools play an instrumental role; they automate optimization tasks such as shell generation or infill pattern adjustment that lead to both material savings and faster print cycles. For instance, modifying a solid gear to have a lattice structure inside its body maintains performance while using less material, effectively trimming costs. Such practical alterations exemplify how thoughtful design decisions can result in substantial financial efficiencies within the realm of 3D printing.

Optimizing Layer Height and Wall Thickness for Economy

To achieve cost-effectiveness in 3D printing, adjusting layer height and wall thickness is essential. Thinner layers yield higher resolution prints but increase print time and material usage, boosting costs. Conversely, a thicker layer height can significantly reduce both factors, albeit at the expense of detail. Optimal economy is often found in a balance that maintains sufficient quality while minimizing resources. Similarly, wall thickness influences material consumption and structural integrity; reducing it may lower costs but risks compromising the item’s strength. Therefore, determining the minimum required wall thickness for your object can lead to material savings without affecting functionality.

Balancing Print Speed with Quality to Minimize Waste

Adjusting print speeds is instrumental in managing 3D printing costs. Higher speeds can decrease printing times and operational costs, yet they may also introduce defects or imperfections that result in wasted materials and additional labor for post-processing. Slower speeds enhance print quality but inflate production times and associated expenses. To economize, operators must find a middle ground, harnessing a speed that maintains an acceptable level of precision while curtailing extraneous expenditures. Mastery of this balance reduces waste from failed prints and conserves resources, ultimately optimizing cost efficiency within the 3D printing process.

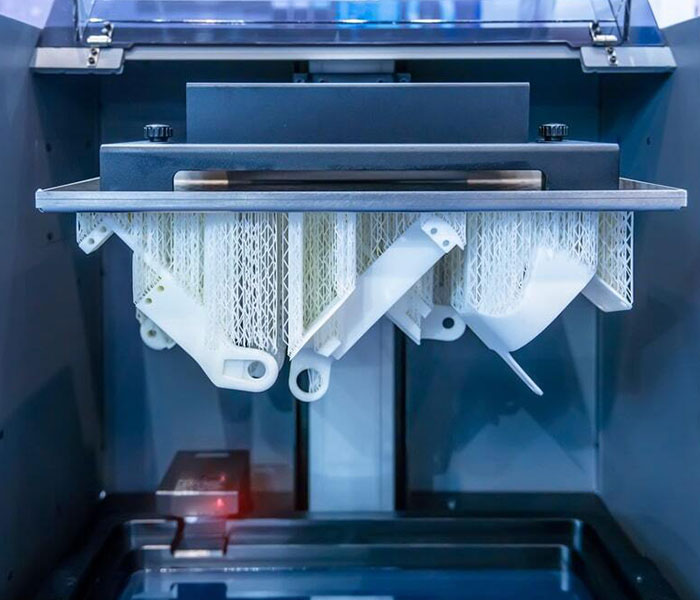

Batch Printing and Part Orientation

Maximizing the efficiency of 3D printing not only relies on the technology itself but also on strategic preparation before the print begins. Grouping multiple parts together in a single print job can significantly optimize the use of available printer capacity, allowing for more components to be produced at once and reducing overall print times. Carefully aligning these parts within the printer’s build volume is an equally critical practice; it minimizes the necessity for support structures that consume additional material and energy. By orienting parts to take advantage of the printer’s geometry, one can ensure stability during the printing process while simultaneously conserving resources. This technique reduces both the material waste from unnecessary supports and the post-processing time needed to remove them, effectively lowering the costs associated with production.

Reducing Post-Processing Needs Through Smart Design

A key way to reduce the cost associated with 3D printing is by minimizing the amount of post-processing required. By implementing smart design strategies, parts can be created that necessitate less finishing work after they have been printed. An example of this could be designing a component with self-supporting angles to avoid the use of additional support structures which would need to be removed and smoothed out later. This approach not only simplifies the production process but also results in significant savings in both time and labor costs, leading to an overall reduction in total cost for producing the part.

Leveraging Economies of Scale

One effective strategy to reduce the cost per unit in 3D printing is by planning larger production runs. By producing a higher volume of components at once, you can distribute the fixed setup costs, such as initial design and machine preparation time, across a greater number of parts, lowering the overall expense for each individual piece. This approach also potentially maximizes the use of materials more efficiently, decreasing waste. For example, nesting multiple designs within the same build volume ensures that not only more items are produced simultaneously but also optimizes printer occupancy, leading to savings on both material usage and operational hours. Operations benefit from the cumulative value of increased quantity without substantially raising production time, ultimately driving down total manufacturing expenses.

Q&A Section: Reducing 3D Printing Costs

Material Savings: How can I save on material costs in 3D printing? One effective method is to explore alternative materials that offer similar properties at a lower price point. For instance, if you typically use ABS plastic, consider switching to PLA for non-essential or prototype components, as it often comes at a reduced cost. Additionally, investigate the possibility of using composite filaments with additives like wood or metal – these can provide unique finishes while potentially reducing the total volume of expensive base plastic used.

Design Changes: What design adjustments can lead to cost reduction in 3D printing? A crucial aspect is optimizing your design to use less material without compromising structural integrity. Incorporating hollow sections or a honeycomb infill pattern achieves this by significantly decreasing the amount of filament needed. Also, consider minimizing support structures through strategic orientation and self-supporting angles above 45 degrees; this will not only reduce material usage but also cut down post-processing time and effort.

Machine Operation Efficiency: How can I optimize my print settings to save costs? Utilizing efficient print settings can drastically enhance resource management. Begin by calibrating your printer accurately to avoid unnecessary waste due to misprints. Select an appropriate layer height–finer layers for high detail prints, and coarser layers for quick prototypes can conserve filament. Moreover, slowing down print speeds may improve success rates and quality, leading to fewer failed prints and wasted material. Intelligently managing active print times by scheduling longer prints overnight also maximizes machine usage efficiency.

Other Articles You Might Enjoy

- 3D Printing Solutions: Bridging the Gap Between Design and Manufacturing

Introduction to 3D Printing Solutions 3D printing solutions represent a transformative advancement in the field of manufacturing. Assuredly, this cutting-edge technology completely redefines traditional methodologies by facilitating seamless transition from…

- Injection Molding Vs 3D Printing: Cost | Pros & Cons (2023)

Injection molding is expected to develop at a compound annual growth rate of roughly 6.2% over the next five years. Its growth is primarily driven by the rising demand for…

- Understanding 3D Printing: Processes, Benefits, and Uses

Introduction to 3D Printing Technology 3D printing, a transformative approach to manufacturing and prototyping, enables the creation of complex structures from digital blueprints by successively layering material until a three-dimensional…