Removing chrome from lightweight metal can pose multiple challenges. Because of the hardness and durability of chrome, it often requires complex procedures to effectively remove it without damaging the base material. This article explores how Computer Numerical Control (CNC) machining technology can simplify this task and provide efficient solutions.

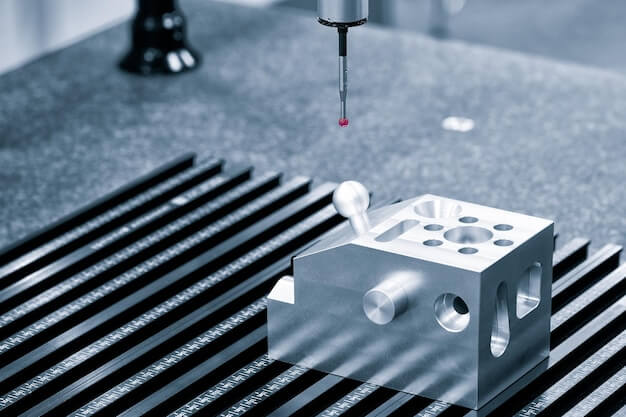

CNC machining is a popular method in manufacturing that offers high precision production through computer-controlled platforms. When removing chrome from metals like aluminum or titanium, this type of machinery enables accuracy, versatility, and minimal damage risk.

To start the process, the proper tooling needs to be selected, specifically for cutting into chrome-plated surfaces. Many might opt for diamond cutters due to their strength, but they are not ideally suited for every application. A more appropriate choice of cutting tools includes carbide end mills or other similar hard-tipped cutters.

Next is programming the machine using CAD/CAM software to ensure precise control over the process. The program will guide the tool’s path and movements to avoid damaging the underlying lightweight metal surface while removing the chrome efficiently.

During the process, safety precautions must be implemented given the hazardous chromium dust generated when stripping off chrome plating. For this reason, all personnel involved should wear necessary protective gear such as goggles, gloves, and masks. Additionally, the right ventilation system for effective dust extraction should be incorporated into the machining setup to maintain safe working conditions.

For larger-scale productions or complex geometries, the use of a CNC router with a rotary/4th axis may come in handy. Its ability to rotate workpieces enables easier access to intricate parts, allowing accurate removal of chrome even from hard-to-reach sections.

One crucial step during chrome removal using CNC machining involves careful monitoring and temperature control. Since high heat may cause thermal deformation affecting both the chrome layer and the base metal, coolant systems should be employed within the machines. The goal is to maintain optimal cutting temperatures which prevent any potential alteration in the material properties or dimensions.

Though debates surface about using chemical methods for further aid, experts warn against this due to potential damage risk to the metal’s integrity. However, a safer alternative could be electrochemical or galvanic stripping of chrome, provided that professional machinery and knowledge are available.

Once chrome removal has been successfully achieved, additional finishing operations might be essential. This can involve polishing or brushing techniques, possibly coupled with protective coatings depending upon where the lightweight metal parts will be used.

In conclusion, CNC machining stands as a prominent method when working on removing chrome from lightweight metals. It offers excellent precision and versatility while maintaining safety procedures essential in such sorts of operations. Embracing modern technology in manufacturing practices not only significantly enhances efficiency but also helps create more sustainable models by reducing waste generated through improper usage.

So whether you’re tackling small-scale projects or handling vast production facilities, understanding how to remove chrome the right way is vital. By leveraging AI-driven, computer-controlled machines, we authenticate an approach where accuracy meets consistency, quality, and eco-responsibility – a win-win situation for both industry players and the planet!

Other Articles You Might Enjoy

- The Role of Magnesium Alloys in Reducing Weight for Automotive CNC Machined Parts?

The Importance of Weight Reduction in Automotive Manufacturing and the Role of CNC Machining In automotive manufacturing, weight reduction stands as a pivotal factor influencing fuel efficiency and performance. Lighter…

- Mastering CNC Machining: Removing Chrome from Lightweight Metal(torsion snap joint Cathy)

Computer Numeric Controlled (CNC) machining has revolutionized the fabrication industry by providing high speed, precision and versatility. One common task in this field is dealing with various metals' unique characteristics,…

- Mastery of Removing Chrome from Lightweight Metal Through CNC Machining( snap fit Dave)

When it comes to machining processes, Computer Numerical Control (CNC) takes a pivotal role in shaping materials precisely and efficiently. This article will shed light on how CNC can help…