The Importance of Weight Reduction in Automotive Manufacturing and the Role of CNC Machining

In automotive manufacturing, weight reduction stands as a pivotal factor influencing fuel efficiency and performance. Lighter vehicles facilitate improved mileage and acceleration along with decreased greenhouse gas emission, which makes it an eco-friendly solution. One essential technique that has emerged to support this weight reduction is Computer Numerical Control (CNC) machining.

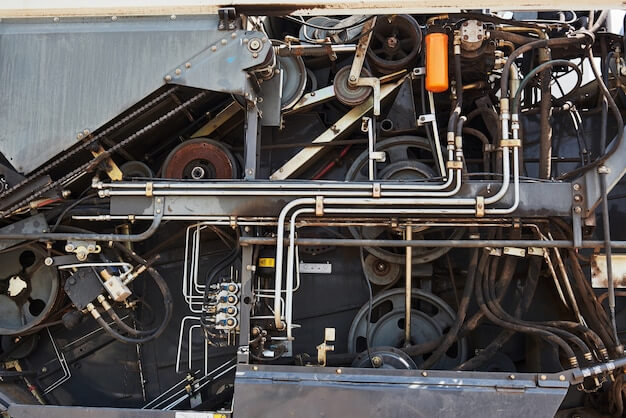

- CNC machining significantly advances the production process through its precise control over intricate parts with complex geometries which traditional techniques might struggle to produce accurately or at scale.

- This high-tech approach can effectively machine a diverse range of materials including magnesium alloys, which are known for their light weight yet strong composition making them ideal candidates for sorting out weight issues of automotive parts.

- Through CNC machining, these magnesium alloy-based components serve to greatly reduce vehicle mass without compromising on structural strength, thereby contributing indispensably towards lightweighting efforts in the automotive sector.

Understanding Magnesium Alloys

Magnesium alloys, a blend of magnesium with other metals, offer key distinct properties that make them ideal for automotive parts. These alloys display an impressive strength-to-weight ratio which means they deliver robust performance without adding excessive weight to the vehicle. This is especially valuable in the automotive industry where reducing vehicle weight is crucial to improving fuel efficiency and lowering CO2 emissions.

- Their superior machinability makes it easier to form complex shapes and designs, thereby widening their applications within the automotive sector.

- In terms of their physical characteristics, they exhibit good resistance to wear and tear, corrosion, and high temperatures – all vital aspects for materials used in manufacturing automotive components.

- Magnesium alloys also possess excellent damping capacity and vibration absorption ability, contributing to smoother rides in vehicles and heavy-duty equipment.

In essence, magnesium alloys tick multiple boxes including lightweight yet strong constitution, superior machinability, and remarkable durability under extreme conditions. These unique attributes position them as a fitting choice for CNC machining processes predominant in the production of automotive parts.

Benefits of Using Magnesium Alloys

Magnesium alloys play a key role in the automotive industry due to their unique properties. Firstly, their lightweight nature contributes significantly to weight reduction in CNC machined parts. This fact reduces fuel consumption and subsequently decreases carbon emissions. Secondly, these alloys have an impressive strength-to-weight ratio, making them ideal for applications that require both lightness and high strength.

- High Corrosion Resistance: They are capable of surviving harsh environments due to their high corrosion resistance, which ensures longevity and durability of vehicle parts.

- Thermal Stability Features: The thermal stability feature allows these alloys to maintain their physical and structural integrity under extremely high or low temperatures.

The use of magnesium alloys is evident in various aspects of motor vehicle manufacturing. For example, they make intricate components such as gearbox casings, steering wheels, brake assemblies, amongst others. As we continue to optimize vehicles’ efficiency and sustainability, the importance of magnesium alloys cannot be understated.

Impact of Reduced Weight on Automotive Performance

The reduction in weight, resulting from the use of magnesium alloys in CNC machined parts, has a direct positive impact on automotive performance. This is particularly seen in the area of fuel efficiency. Lightweight vehicles consume less energy as there is less mass to move; hence, fuel consumption is reduced and mileage is improved. Research suggests that for every 10% decrease in vehicle weight, fuel economy can be increased by 6-8%. In addition to enhanced fuel efficiency, reducing the weight also improves car safety and handling.

- Safety: Heavier vehicles are often harder to control especially during sudden braking or steering maneuvers. A lighter car will have shorter stopping distances, faster acceleration and more agile cornering. These attributes significantly enhance vehicle safety.

- Handling: Another notable improvement due to reduced weight sits within improved maneuverability and responsiveness. A lightweight car responds better to driver inputs such as steering, accelerating, and braking – all crucial factors in efficient driving.

Magnesium alloys thus prove to be integral in enabling these benefits while maintaining structural integrity. The high strength-to-weight ratio gives manufacturers the performance edge they need without compromising on vehicular quality and enduringness.

Process of CNC Machining with Magnesium Alloys

When considering the CNC machining process with magnesium alloys, it’s essential to partner with a online CNC service provider that specializes in precision machining. Magnesium alloys offer the advantage of combining strength with low weight, making them ideal for use in automotive parts to reduce overall vehicle weight and improve fuel efficiency.

Environmental Sustainability Aspect of Magnesium Alloys in CNC Machining

Magnesium alloys play a crucial role in improving environmental sustainability within the automotive industry. Their lighter weight significantly reduces material usage, facilitating sustainable manufacturing practices and minimizing carbon footprints. A vehicle’s weight directly influences its fuel efficiency and thus, emission standards. For instance, lighter vehicles often exceed emission standards due to their enhanced fuel economy.

- The reduced mass requires less energy for acceleration, resulting in lower CO2 emissions.

- The decreased load on tyres reduces particulate matter emissions released from tyre wear.

- Lighter vehicles also demand smaller and lighter components, further lessening the overall raw materials consumed in their production process.

This multifaceted positive impact maintains robust environmental implications. Thus, through magnesium alloys in automotive CNC machined parts, we can make strides towards eco-friendlier automotive engineering.

Challenges and Solutions In Implementing Magnesium Alloys

Manufacturing with magnesium alloys is a critical task due to certain challenges. Key issues can include the high costs associated with their production, processing, machining, and even the specialized equipment needed for their handling. Furthermore, despite their lightweight, magnesium alloys have lower durability as compared to steel or aluminum, raising concerns over long-term performance.

To address these challenges, several research projects are underway. Among potential solutions:

- Exploring alternative production methods that could substantially reduce cost factors,

- Finding effective treatment procedures to increase the material’s hardness and hence its durability,

- Improving heat-treatment techniques to enhance strength and corrosion resistance of magnesium alloys,

- Developing hybrid designs that combine magnesium with more durable materials without increasing weight significantly.

The continuous development in this field promotes optimism about overcoming these hurdles and optimizing the use of magnesium alloys for automotive applications.

Other Articles You Might Enjoy

- Mastering CNC Machining: Removing Chrome from Lightweight Metal(torsion snap joint Cathy)

Computer Numeric Controlled (CNC) machining has revolutionized the fabrication industry by providing high speed, precision and versatility. One common task in this field is dealing with various metals' unique characteristics,…

- Efficiently Removing Chrome from Lightweight Metal Using CNC Machining(titanium vs aluminum Miriam)

Removing chrome from lightweight metal can pose multiple challenges. Because of the hardness and durability of chrome, it often requires complex procedures to effectively remove it without damaging the base…

- Mastery of Removing Chrome from Lightweight Metal Through CNC Machining( snap fit Dave)

When it comes to machining processes, Computer Numerical Control (CNC) takes a pivotal role in shaping materials precisely and efficiently. This article will shed light on how CNC can help…