Introduction to High-Precision CNC Machining in Cutting-Edge Biotechnology

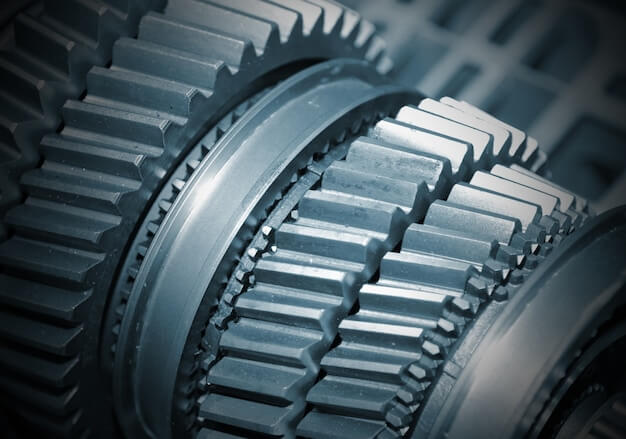

CNC (Computer Numerical Control) machining is a prominent automated manufacturing process that manipulates tools around multiple axes with computer-driven precision. Significantly, it provides an enhanced level of control and accuracy necessary for biotechnological applications where high levels of precision and consistency are required. In cutting-edge biotechnology, precise CNC machining aids in the development and creation of intricate biological components or devices such as diagnostic tools, prosthetic parts, implants, and microfluidic chips.

- Diagnostic tools: For instance, some bio-CNC machines can produce nano-scale features required for sophisticated medical diagnosis devices.

- Prosthetic parts and Implants: These are designed using CNC technology to achieve improved fit and comfort along with optimized functionality.

- Microfluidic Chips: The application also extends to fabricating microfluidic systems used in lab-on-a-chip technology, invaluable for biochemical analysis, creating terrain-like simulations on a chip surface.

Thus, high-precision CNC machining has emerged as a nexus between mechanical engineering and biotechnology, pushing boundaries and inciting breakthroughs in the field.

High-Precision CNC Machining: Definition, Process, and Importance:

- Step 1: CNC machining is a subtractive manufacturing process that utilizes computerized machine tools to create custom-designed parts with exceptional precision.

- Step 2: The process involves the removal of materials from a workpiece to achieve high tolerances and excellent surface quality, making it crucial for cutting-edge biotechnology applications.

- Step 3: To understand the importance of high-precision CNC machining in biotechnology, explore resources such as RapidDirect’s knowledge base for comprehensive insights and information.

Applications of High-Precision CNC Machining in Biotechnology

The relevance and use cases of high-precision Computer Numerical Control (CNC) machining expand into several areas of sophisticated biotechnology such as gene editing, production of diagnostic tools among others. The precision inherent in CNC processes ensures unmatched efficiency ideal for manipulating genetic structures critical in gene splicing and editing tasks. This is particularly important as it significantly reduces potential errors that could result in unwanted mutations or inaccuracies.

CNC machining’s precision is not only needed in gene modification but also finds a crucial place in the manufacturing of advanced diagnostic tools indispensable to modern biotech research and medical diagnostics. Here, CNC techniques ensure devices like endoscopes and micro-cameras are created with exceptional accuracy, aiding doctors in precise diagnosis and treatments.

One notable example is the utilization of high-precision CNC machining methods in fabricating DNA sequencers. Given the minute size of DNA molecules, constructing a machine capable of accurately analysing these complex structures necessitates extremely precise manufacturing processes. By using high-precision CNC machines, manufacturers can create components of DNA sequencers with exactness down to micron levels, thereby substantially increasing accurateness of sequencing results.

Advantages of Using High-Precision CNC Machining for Biotechnology

The application of high-precision Computer Numerical Control (CNC) machining in biotechnology comes with notable advantages. For instance, one major benefit is the enhanced accuracy it introduces to operations leading to more reliable research outcomes. With the superior precision provided by CNC technology, intricate and minute details involved in biological processes can be effectively handled reducing instances of errors that could compromise overall results.

- CNC’s automated features streamline workflow, consequently making time utilization efficient.

- They eliminate the need for manual labor, thus freeing up valuable time spent on repetitive tasks.

- This gains significance especially when dealing with large scale lab procedures where speed is as equally important as precision.

In sum, the incorporation of high-precision CNC machining into biotechnology proves to be a transformative move due to its exceptional ability to markedly improve operation accuracy, boost productivity and ultimately enhance both reliability and efficiency of research outcomes.

Comparison between Traditional Methods and High-Precision CNC Machining in Biotechnology Manufacturing

The manufacturing process in the biotechnology sector has been predominately ruled by conventional methods, which encounter several limitations. Time-consumption, cost-inefficiency and a lack of scalability negatively impact overall productivity. For instance, these traditional techniques often involve laborious procedures with numerous stages, consequently extending production time. Moreover, manual intervention increases the probability of errors leading to considerable waste, hence elevating production costs. This inefficiency restricts mass production, as scaling up becomes unfeasible within reasonable economic constraints.

Contrastingly, high-precision CNC (Computer Numerical Control) machining brings game-changing advantages in overcoming such limitations. CNC machining dwarfs its predecessors in aspects like:

- Time consumption: being entirely computer-operated, it hastens the workflow cutting down the processing times significantly.

- Cost-efficiency: Automated controls minimise human error, reducing waste and thus ultimately decreasing the per-unit manufacturing cost.

- Production Volume: reproducibility afforded by precise automation enables extensive scalability, thereby facilitating larger production volumes without compromising on quality or speed.

In essence, high precision CNC machining presents transformative solutions for advancing biotechnology manufacturing.

Future Impact and Possibilities of High-Precision CNC Machining in Biotech

The future impact and possibilities of high-precision CNC machining in biotechnology are immensely promising. With technological advancements, it is feasible that leading-edge precision machining could lay the groundwork for progressions such as artificial organs. This concept might have seemed unrealistic decades ago but with advancements in 3D printing and the level of accurate detailing provided by CNC machines, it ceases to remain a far-fetched dream.

- Highly precise surface details and internal structures can be created with today’s advanced software capabilities combined with CNC machining technology which forms an optimal solution to create synthetic tissues and potentially entire organs.

- These transformative technologies would not only make organ donations obsolete but save millions of lives waiting on transplant lists.

This revolution powered by CNC machining will propel the wider biotechnology industry into new, unchartered territories. The ability to design and fabricate flawless microscopic components or manipulable biomaterials efficiently will open up endless research possibilities while simultaneously enhancing the productivity, profitability, and lifespan of products and solutions from bio-industries.

Other Articles You Might Enjoy

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Exploring Bead Blasting in CNC Machining(cnc machining services china Nicole)

Bead blasting is a process used extensively in the world of computer numerical control (CNC) machining. A standard part of many businesses, bead blasting enriches various products that we use…

- Understanding Bead Blasting in CNC Machining(china machining Avery)

Bead blasting, a compelling term in the world of Computer Numerically Controlled (CNC) machining, is an influential process that plays a transformative role in optimizing and enhancing parts' aesthetic and…